Recycling is a fixed cost business – it does not vary with the price of oil or the price of natural gas – and the more willing potential customers are to pay on a fixed cost basis, to cover the collection, separation, cleaning, and re-pelletizing costs, the more recycled material will make it back into the cycle and not into landfill or pyrolysis. The pyrolysis technologies being discussed by the major polymer producers are a solution to the plastic WASTE problem, and they allow for a degree of recycling potentially, but they will never be able to bid waste polymer away from a mechanical recycling alternative if the buyer is willing to cover the costs. We have written extensively on these topics in our ESG and Climate reports and we would point readers back to Unwanted: Chemical Recycling – Necessary Now, Less So Later and the second section of True Blue: Not Green but Likely Good Enough.

Pyrolysis Will Never Win If Consumers Are Willing To Pay For Recycled Plastics

Apr 30, 2021 1:46:22 PM / by Graham Copley posted in Recycling, Polymers, Plastic Waste, Plastics, Pyrolysis, Mechanical Recycling

Ideal Plastic Waste Facility and Carbon Neutral Carbon Black!

Apr 8, 2021 12:46:20 PM / by Graham Copley posted in ESG, Plastic Waste, Carbon Black

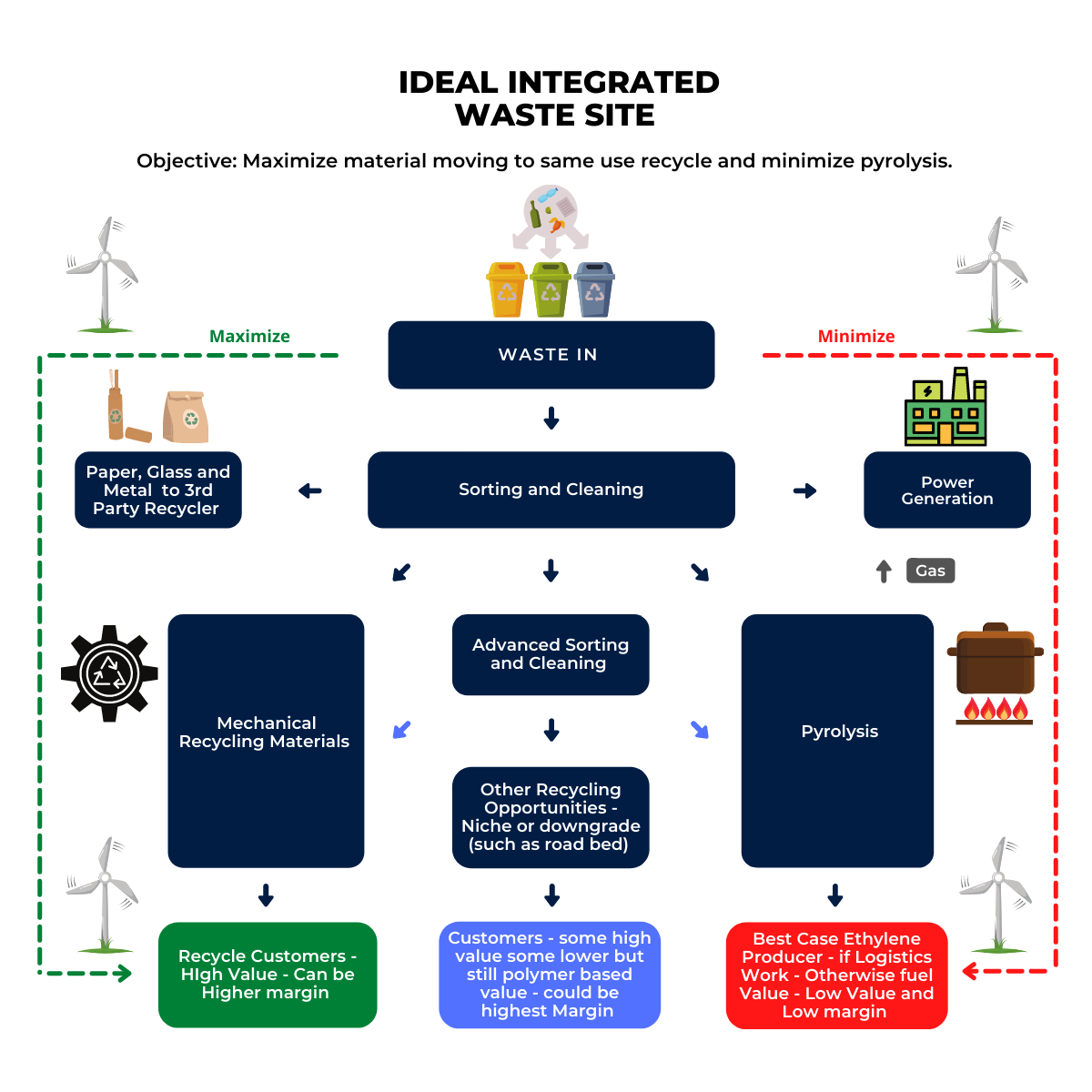

Given the complexity of solving both the climate and the plastics waste issues, both of central importance to the chemical industry, we are very much of the view that you should try everything. No single technology or pathway is likely to be the answer and different solutions may have different levels of attraction in different geographies. In our ESG and Climate weekly report yesterday, we spent time talking about recycling and how the business might logically develop and we talked about where blue and green methanol might fit.

Plastic Waste Challenges Revisited

Mar 11, 2021 11:20:12 AM / by Graham Copley posted in Recycling, Polymers, Plastic Waste

We are back on plastic waste today, following the IHS World Petrochemical Conference post that collaboration is key to evolving the circular plastics economy, reminding us what the largest challenge is regarding creating a circular plastics economy. Our work on trying to find a waste solution for a specific source material that we have discussed in prior reports has shown us firsthand how difficult it is to get the parties that should be interested in collaborating to talk to each other. While some see the waste problem as an urgent need, generally those that have the waste and are looking for a solution, others that are needed to complete the chain, have the issue far down their list of priorities. Making matters worse is that the margin in the collection, sorting, and then finding the most appropriate home for different streams of waste, is very small unless you are very efficient and/or unless you know that you are getting a disproportionate amount of material that can be upgraded (mechanically recycled) versus downgraded (chemically recycled).

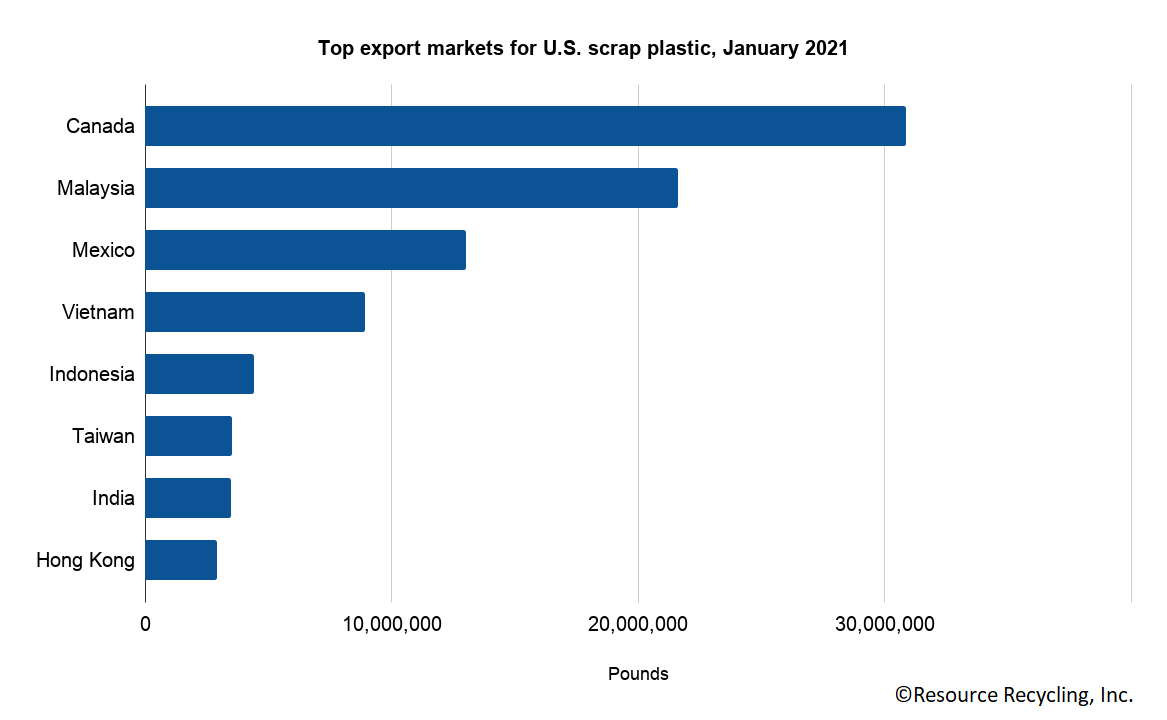

An added complication is that when China was taking waste, there was a payment for the mixed plastic and consequently, many who were involved in that trade are used to being paid for the waste – and have higher expectations of the margins to be shared than are likely available – in other words they want more for the plastic than it is worth locally, especially in a downgrading chemical recycling process.

Source: ResourceRecycling, US Census Bureau

In the chart above, it is likely that the prices being paid for the plastics that are being exported are very low and we have seen instances of local municipalities paying to have waste removes as it is less expensive than landfill – this is a mindset that is needed broadly to generate solutions for waste disposal and the optimal use of the various plastic waste streams. IHS is spot on with its call for greater collaboration, but that collaboration is not at a national level as the waste polymer is spread nationally and internationally and is a problem for local municipalities, counties and if they are coordinated, States, within the US. It is not one instance of collaboration and investment that is needed - it is thousands and while some solution investments may be common, many may not be. This one of the reasons why we believe that the chemical recycling ambitions of the chemical majors are wildly optimistic, given that outside of very large urban centers, they will need to work with hundreds of distinct local groups to get more material into the system. There is much more on plastic waste and recycling options in our March 3rd ESG and Climate Piece - Trash, or Treasure: Waste Plastic Challenges and Opportunities