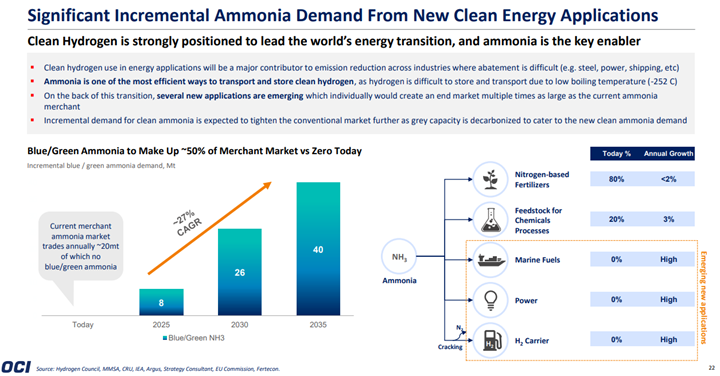

There is the potential for the ammonia thirst (please don’t drink it) to surpass opportunities to build cost-effective capacity for the medium term. Consequently, the shortages we see today could extend and become more severe. Co-firing coal-based power facilities in Asia is one of the more obvious ways to start decarbonizing a predominantly coal-based power region. The experiments in Japan, if successful, will drive a step-change in demand for blue or green ammonia, and this should drive much more new capacity than we have seen announced to date. The power-based demand comes on top of expected growth in fertilizer-driven demand and a possible rise as a shipping fuel. The issue for investors is that green ammonia at scale is economically challenging, especially with the recent shortfalls in renewable power generating plans and what now looks like rising power costs for a while. Blue ammonia is much easier to think about at scale, but we are still hamstrung by expensive carbon capture costs and a lack of incentives – either in terms of tax breaks or taxes or in terms of a customer willing to pay more, to get most ideas and plans past the “wouldn’t it be nice” phase. In the meantime, as indicated above, installed ammonia capacity is making abnormal returns.

Shortages: Ammonia, Affordable Ethanol, & Renewable Power In The Right Places

May 12, 2022 2:01:48 PM / by Graham Copley posted in Polyethylene, Ethylene, Renewable Power, Ammonia, ethanol, blue ammonia, Braskem, fertilizer, reshoring, green ammonia, sugar, green polyethelyne

Green Polyethylene Will Be Important But Costs Will Matter

Mar 18, 2022 11:39:46 AM / by Graham Copley posted in ESG, Polymers, Climate Change, Sustainability, Polyethylene, Ethylene, packaging, ethanol, renewable polymers, renewables, Braskem, crude oil, sugar cane, sugarcane

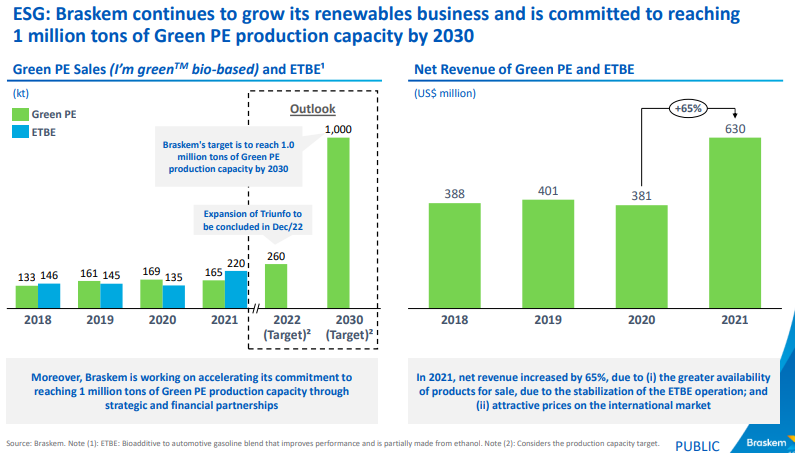

Braskem’s green polyethylene is an interesting niche opportunity, but we question how big the market might be for a product where you need the buyer to agree to prices that cover your costs – i.e. how many buyers will potentially pay up. In a $100 per barrel crude oil environment, polyethylene from sugar cane likely looks quite attractive, but probably less so in a $50 crude environment. Sugar cane-based ethanol has a cost advantage over corn-based ethanol, and one of the key questions for Braskem is how do you grow the business outside Brazil, where the barriers to entry for others are not much different. We do not doubt the demand potential for green polyethylene and other ethylene derivatives, but our concerns would be how to profitably grow the business, especially if there is a lower crude oil price backdrop. Today it is easy to make a bull case for oil – we do so above – but note that oil forecasting is not our strength and nor is it anyone else’s – based on hindsight. Paying a 20% premium over fossil fuel-based polymers may make sense for some packagers with meaningful ESG goals, but a 100% premium is likely unstable.

Carbon Footprints Matter, For Polymers And LNG

Nov 18, 2021 1:55:23 PM / by Graham Copley posted in ESG, Hydrogen, Recycling, Polymers, LNG, Polyethylene, CCS, Ethylene, decarbonization, HDPE, carbon abatement, ethane, naphtha, climate, carbon footprints, recycled polymers, virgin polymers, fuel, Freeport LNG

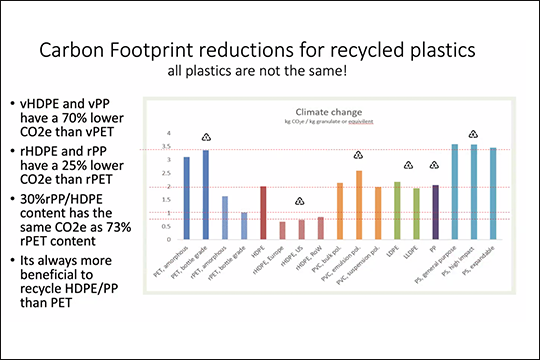

It is interesting to watch the pivot between recycled versus virgin polymer to the carbon footprint of the various options as outlined in the chart below. We are assuming that the numbers in the chart are averages as there is a sizeable range for everything. As we note in today's daily report, ethylene feedstock will impact the carbon footprint of ethylene and consequently, the footprint of polyethylene – HDPE made from ethane based ethylene in the US where the ethylene producer is recycling hydrogen back into the furnaces, will have a much lower carbon footprint than HDPE made from naphtha based ethylene in Europe, for example. On the recycling side, there will also be a range based on transportation costs for collection and sorting and then distribution to a customer.

ESG Friday Question: Can Technology Keep Pace?

May 21, 2021 1:12:36 PM / by Graham Copley posted in ESG, Carbon Capture, Ethylene, Emissions, Net-Zero, IEA, Dow, propane, Technologies, ethane dehydrogenation, carbon footprint, BASF

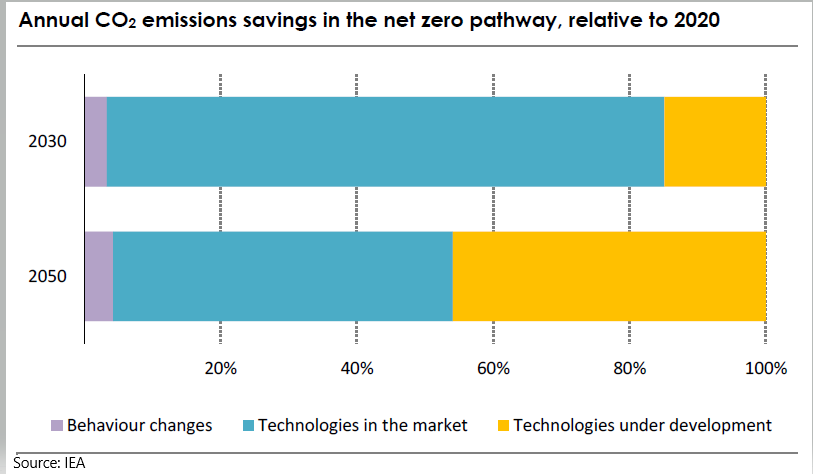

There is a broad technology theme to the articles that we have chosen today, which is in keeping with one of the core conclusions of the IEA report earlier this week. The IEA is estimating that roughly half of the path to net-zero will require technologies still in the test phase, or in some cases still conceptual. The Dow headline around ethane dehydrogenation and electric furnaces is a good example. Both technologies could lower the carbon footprint of making ethylene, but the dehydrogenation route will require some catalyst or other breakthrough as current propane dehydrogenation technologies require a lot of heat. The electric furnace idea is complex and would require extremely high levels of power, all of which would have to be renewable for the carbon footprint to fall – this type of technology is likely implied in the BASF announcement today. The IEA talked about some of the transition moves required to allow the technology advances time to become either commercial or cost effective, or both. Carbon capture features meaningfully in the IEA plans, but the study has carbon capture volume rising through 2050, which we find odd. The idea of carbon capture is to act as a bridge between where we are today and where we could be once new technology is developed – therefore, while companies like Dow should be aiming for technologies that lower the carbon production of its processes, carbon capture should be an almost immediate bridge to lower emissions while both the technology is developed, and its costs are reduced. Carbon capture needs should then decline. View today's Daily Report for more.

A Novel Technology, But Are There Better Uses For The Renewable Power?

Mar 24, 2021 1:08:33 PM / by Graham Copley posted in Ethylene, Renewable Power

We don’t want to throw cold water on a very HOT idea, but the BASF, SABIC, Linde announcement of collaboration on electric furnaces for ethylene production is not the first that we have seen, as both Dow and Shell have stated that they are looking at similar ideas. As an “endgame” objective this is interesting, as it would remove the need for natural gas fuel and greatly reduce emissions, but despite the claims in the release, this is an interesting pilot project at best today. It is a credible process, and the companies have likely achieved ethylene production this way on a lab scale. It is possible to get significantly higher temperatures today through electric power than the 800c (1500f) suggested in the article. Some plasma jet technology can achieve temperatures in the 1000s of degrees centigrade, but the power consumption is extremely high, and it is worth noting that the press release does not mention the possible power requirements to get to a metric ton of ethylene. Modern ethylene units produce a million tons a year (or more) – which is around 2 metric tons per minute. The better technologies involve raising the feedstocks to very high temperatures very quickly (measured in fractions of a second). The partners talk about achieving electric power-based ethylene at scale. This is a lofty goal. Should they succeed, not only would ethylene plants require significant retrofitting at the front end at very high capital cost, but the power requirements would be enormous, putting even greater strain on global and regional renewable power ambitions, that already looks hard to achieve, given all of the competing needs. We would want to ask two questions:

- Are you better off making hydrogen and using hydrogen as a furnace fuel in a traditional and well-practiced ethylene process – this would likely mean much lower capital refit costs?

- Are you better off still just capturing and sequestering the CO2 from existing facilities?

Photo by Linde Engineering. The ethylene furnaces are in the background to the right of the picture

With many of these “cleaner” objectives and theoretical technologies, there may be other more practical workarounds, and if not they still probably do not make sense until there is such an abundance of renewable power that the incremental cost of power is very low for 95% of the time.