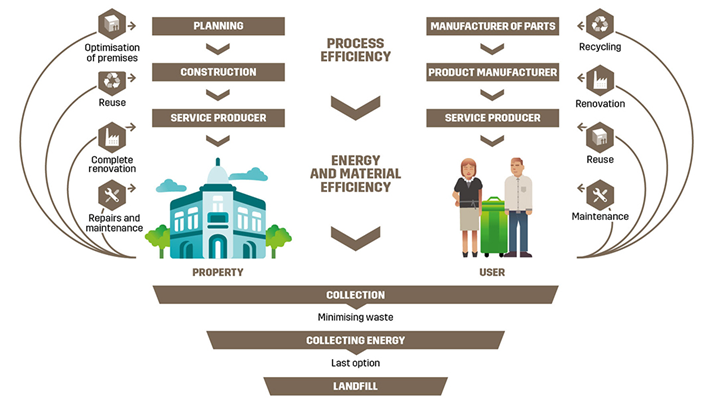

We tend to focus on recycling conventional plastic waste, but there are growing initiatives to look at the longer life cycle of durables and while this has mostly been focused on the automotive space, it is interesting to see the building industry looking at building life cycles. Many of the alternative use mechanical recycling initiatives are directed toward substituting building products such as concrete and wood and while this will help the construction sustainability story, the end of life cycle issue is less clear. The majority of commercial real-estate emissions are associated with operations (around 70%) and this is the greater focus for owners today, but the life cycle question is increasingly important for building tenants. In the UK for example there are redevelopment projects proactively advertising how much of the original building will be retained – i.e. not demolished and landfilled. Ultimately this might lead to lower demand for commercial building products where developers are looking at existing buildings, but it will not impact new greenfield builds unless you get a steep increase in recycled polymer use. The offset would likely be concrete as this is the high carbon footprint material that most are targeting. See more in today's ESG and Climate Report.

It's Not Just Packaging That Needs To Be Recycled

Mar 30, 2022 11:55:43 AM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Sustainability, Plastic Waste, Plastics, Emissions, packaging, durables, carbon footprint, polymer, recycle, materials, Building Products, construction, life cycle, greenfield, building industry, recycled materials

Green Polyethylene Will Be Important But Costs Will Matter

Mar 18, 2022 11:39:46 AM / by Graham Copley posted in ESG, Polymers, Climate Change, Sustainability, Polyethylene, Ethylene, packaging, ethanol, renewable polymers, renewables, Braskem, crude oil, sugar cane, sugarcane

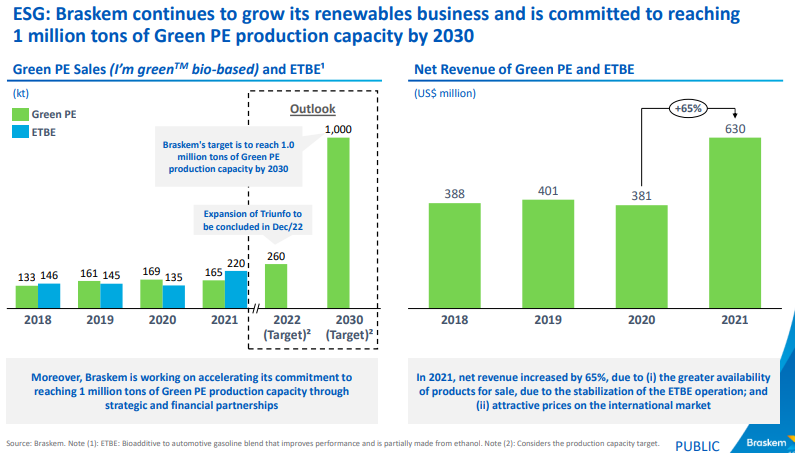

Braskem’s green polyethylene is an interesting niche opportunity, but we question how big the market might be for a product where you need the buyer to agree to prices that cover your costs – i.e. how many buyers will potentially pay up. In a $100 per barrel crude oil environment, polyethylene from sugar cane likely looks quite attractive, but probably less so in a $50 crude environment. Sugar cane-based ethanol has a cost advantage over corn-based ethanol, and one of the key questions for Braskem is how do you grow the business outside Brazil, where the barriers to entry for others are not much different. We do not doubt the demand potential for green polyethylene and other ethylene derivatives, but our concerns would be how to profitably grow the business, especially if there is a lower crude oil price backdrop. Today it is easy to make a bull case for oil – we do so above – but note that oil forecasting is not our strength and nor is it anyone else’s – based on hindsight. Paying a 20% premium over fossil fuel-based polymers may make sense for some packagers with meaningful ESG goals, but a 100% premium is likely unstable.

Market For Renewably Source Polymers Is Growing

Feb 25, 2022 1:52:40 PM / by Graham Copley posted in ESG, Polymers, Climate Change, Sustainability, renewable polymers, renewables, polymer demand, Origin Materials

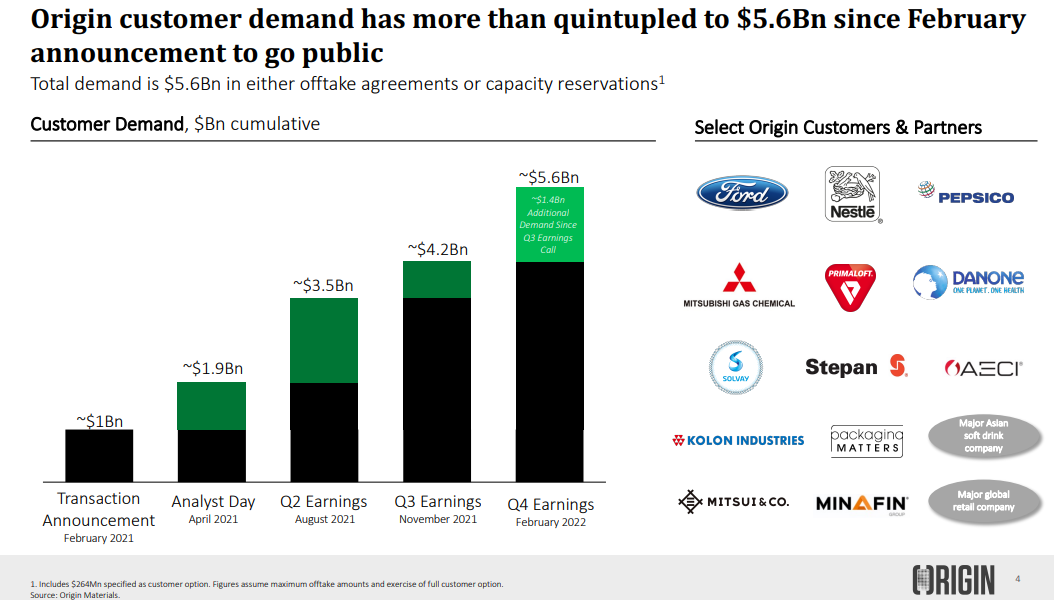

Origin Materials reported earnings yesterday and the highlight was the further increase in possible customer demand for the products the company plans to make, as well as the recent announcement of a second US plant. In our ESG and Climate piece on Wednesday, we talked about how important it is going to be for these new technology companies to have bankable offtake agreements, as these will be needed to support funding, given the more cautious outlook that the market has towards project finance today and the concerns over rising rates. The products that Origin expects to make should have robust demand, and they should attract a whole bunch of interested customers, all of whom are struggling with their own ESG dialogue. The question around Origin is whether the technology can deliver the products at costs that make sense and in reliable volumes. The story looks good if the process does what is promised.

Bioplastics: Probably Important But Small For Now

Dec 7, 2021 2:50:00 PM / by Graham Copley posted in ESG, Recycling, Polymers, Sustainability, Plastics, biodegradable, ESG investment, climate, plastics industry, biodegradable polymers, biodegradable plastics, polymer demand, bioplastics

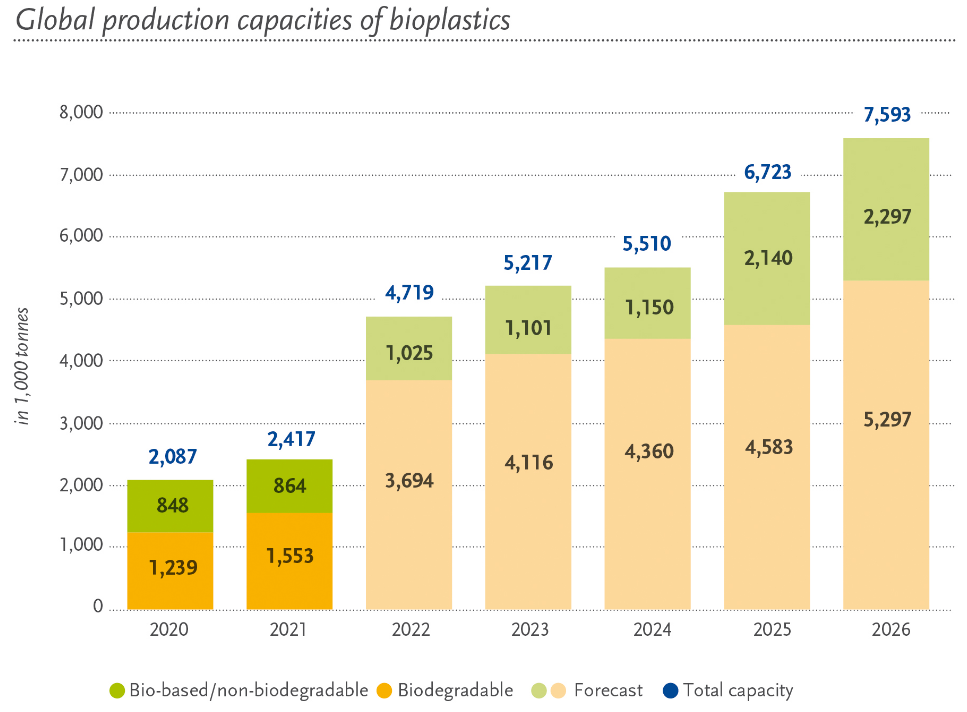

The bioplastics chart below (from today's daily report) is interesting from a couple of perspectives, the first being whether the projections are reasonable and the second being the significance of the investments. We believe that the volume targets are optimistic, given the capital requirements and that many of the companies pursuing bioplastics are relatively new and need to borrow most or all of the capital needs. The volumes would be easier to believe if the participants were large companies with strong balance sheets. The second point is just how small the volumes are in the grand scheme of plastics. Global demand for plastics exceeds 300 million tons and consequently, the 2026 projection would account for only 2.5% of global polymer demand. Note that in the article (linked here) around the uptake of biodegradable plastics – in this case in the UEA – one of the constraints to growth listed is availability. The other constraint, which likely faces producers in all markets is consumer education. Introducing a new polymer – or range of polymers – into an already confusing mix will require consumer education around what is biodegradable and what to do with the material. This topic follows on from the recycling theme in last week's ESG and Climate Report.

Carbon Footprints Matter, For Polymers And LNG

Nov 18, 2021 1:55:23 PM / by Graham Copley posted in ESG, Hydrogen, Recycling, Polymers, LNG, Polyethylene, CCS, Ethylene, decarbonization, HDPE, carbon abatement, ethane, naphtha, climate, carbon footprints, recycled polymers, virgin polymers, fuel, Freeport LNG

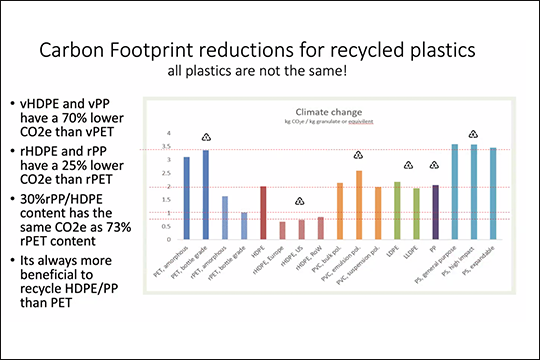

It is interesting to watch the pivot between recycled versus virgin polymer to the carbon footprint of the various options as outlined in the chart below. We are assuming that the numbers in the chart are averages as there is a sizeable range for everything. As we note in today's daily report, ethylene feedstock will impact the carbon footprint of ethylene and consequently, the footprint of polyethylene – HDPE made from ethane based ethylene in the US where the ethylene producer is recycling hydrogen back into the furnaces, will have a much lower carbon footprint than HDPE made from naphtha based ethylene in Europe, for example. On the recycling side, there will also be a range based on transportation costs for collection and sorting and then distribution to a customer.

Recycle Availability Still Expected To Be A Headache For Packagers

Nov 16, 2021 1:02:05 PM / by Graham Copley posted in ESG, Recycling, Polymers, Sustainability, PET, Coca-Cola, polymer producers, renewable polymers, chemical recycling, low carbon, PepsiCo, Unilever, zero carbon, recycled polymers, FMCG, recycling goals

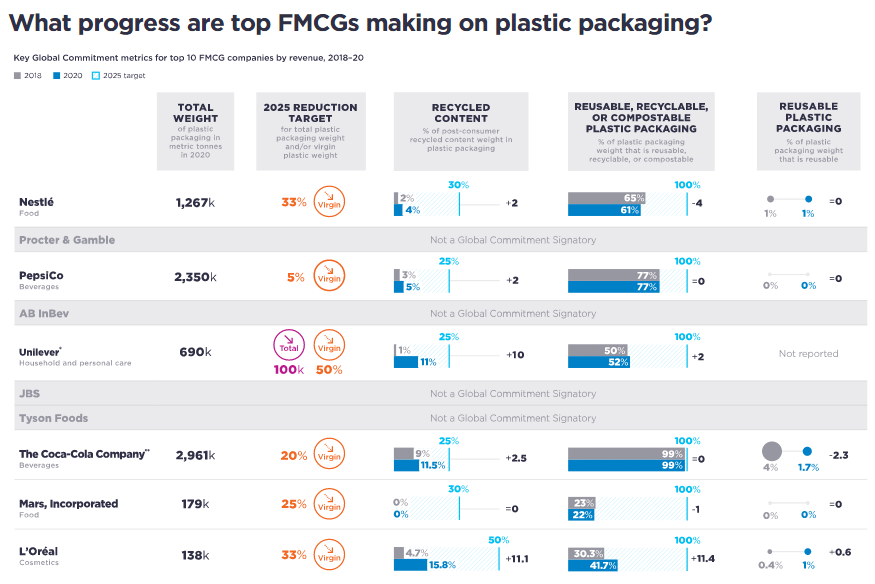

The chart below on recycling progress by the major FMCG companies is timely as it bumps into plenty of “national recycling day” headlines which include as many stories around recycling polymers into new applications as stories about like for like recycling. The more polymer that moves through collection and sorting and into roadbeds or composite particleboard replacement, etc., the less there is available for the FMCG companies to meet recycling goals. We see this as a major opportunity for the renewable polymer makers, but it is unlikely that there will be enough renewable-based polymers available to close the 2025 gap for most of the companies listed below. What is likely, in our view, is that the packagers will embrace chemical recycling as a way to increase their recycled content and will strike very specific deals with those able to show a chain of custody from collection through new polymer production.

Hydrogen Investments: Companies Weighing Alternatives As They Should

Oct 5, 2021 1:36:33 PM / by Graham Copley posted in ESG, Hydrogen, Polymers, Climate Change, Sustainability, CCS, Renewable Power, Emissions, Net-Zero, ethylene producers, Climate Goals

The gaps in the exhibit below are not surprising as 2050 is a long way away and we would not expect all of the needed capacity to be announced or pledged yet, especially as many companies are still weighing alternatives. For example, as an ethylene producer, you have 5 paths – hydrogen as a furnace fuel – electric power as a heating medium – stick with what you have and use CCS – find an alternative route to make the polymers – make alternative polymers.

Food Grade Plastic Proving Difficult To Recycle - Pyrolysis Is The Answer

Aug 26, 2021 12:40:00 PM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Plastic Waste, Plastics, Pyrolysis, chemical recycling, reuse, food packagers, food-grade polymer

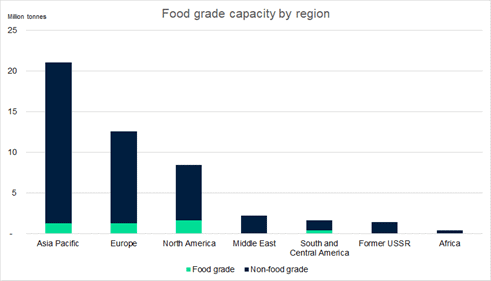

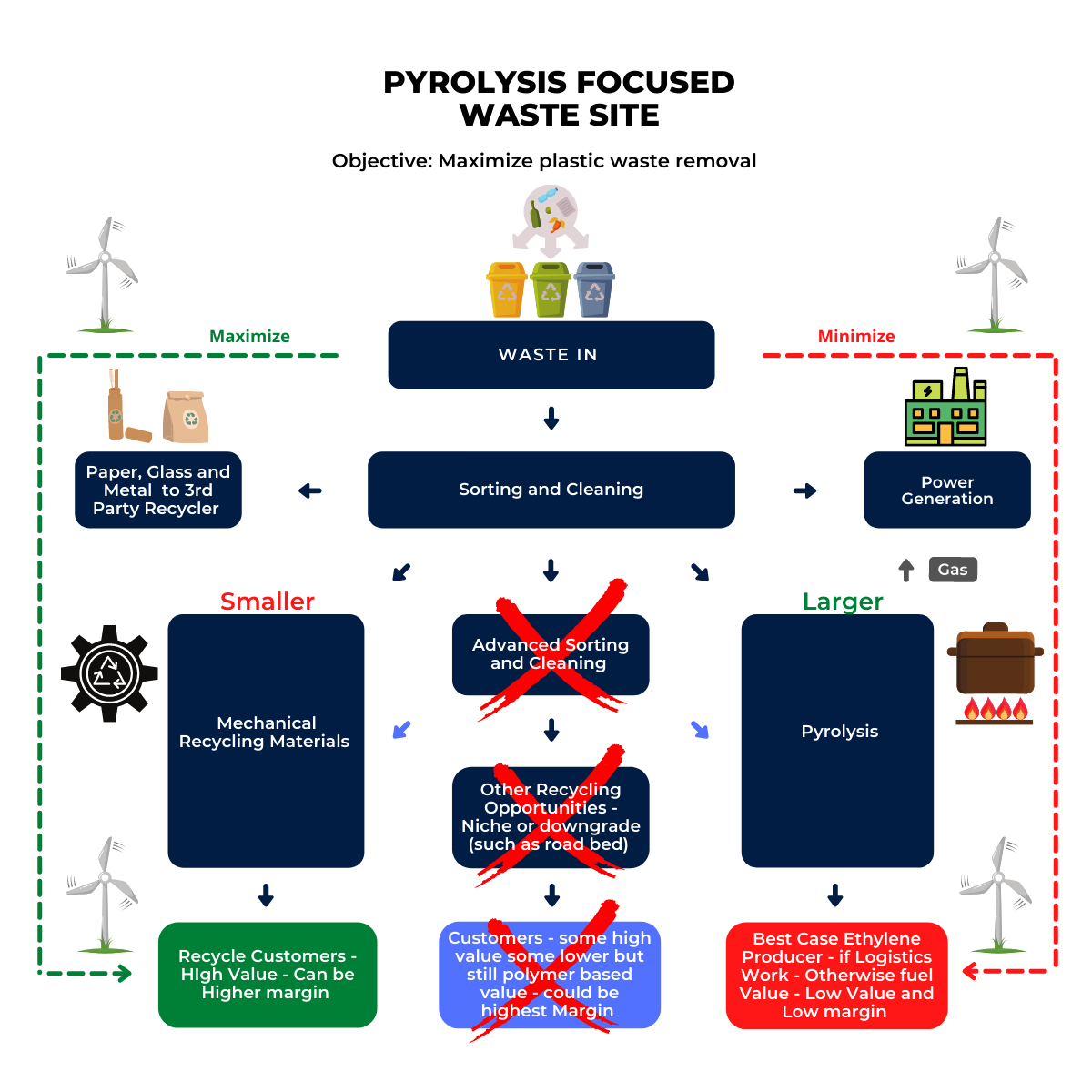

The exhibit below will come to many as a surprise, and it underlines one of the most significant challenges facing the recycling world. It is the food packagers who want the recycled content, but most food-grade polymer is not easily recycled (mechanically) once it has been in contact with food. Shrink-wrap for example is hard to collect and even harder to clean to a standard that is deemed safe and then hard to regrind because it is thin-film. This is where the polymer industry can really push the benefits of “advanced” chemical recycling as the process can take a mixed and not thoroughly cleaned stream of waste polymers with the recycling process itself (pyrolysis) destroying the contaminants and for the output that gets redirected back to ethylene units an additional shot at 1600-1700 Fahrenheit should remove any fears of contamination. You will not get the pound for pound recycle, but 35% is much better than the numbers suggested in the chart. Plus, in the process, you can destroy and reuse a great deal of plastic waste. See our ACC initiative write-up in yesterday’s ESG and Climate report.

100% Recycling: A Bold But Necessary Ambition For The ACC

Aug 25, 2021 1:33:16 PM / by Graham Copley posted in ESG, Recycling, Polymers, PVC, Plastic Waste, Plastics, chemical recycling, packaging polymers, ACC, plastics packaging, reuse, recycle, recover

The ACC goal of recovering 100% of packaging polymers is bold but likely necessary to show that its members are focused on a full solution, rather than some sort of halfway step. The goal is broken down as follows:

Carbon Capture: Front and Center & Enabling Hydrogen Growth

Aug 5, 2021 1:17:52 PM / by Graham Copley posted in Hydrogen, Chemicals, Carbon Capture, Polymers, Green Hydrogen, CCS, Blue Hydrogen, Emissions, Emission Goals, natural gas, carbon emissions, CBAM, NGLs, gray hydrogen

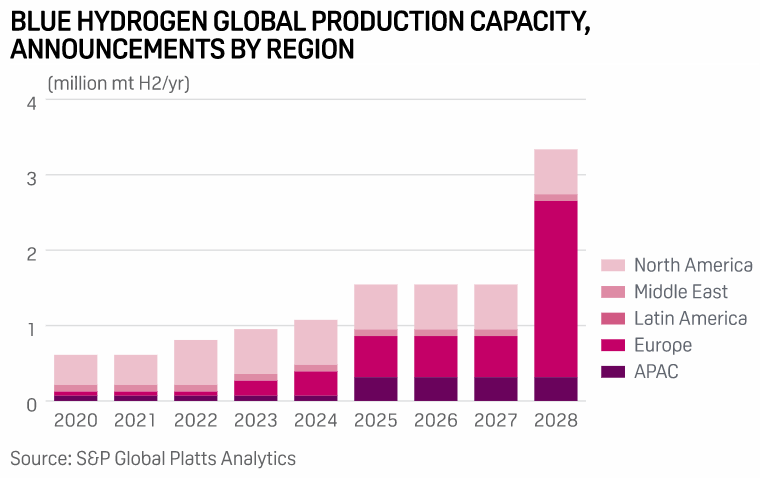

The primary reason for the flurry of carbon capture related headlines in the US over the last few weeks – and our analysis shows a significant step up – is because it looks like this will be the one technology/route to lower carbon emissions that will get a real boost from the infrastructure bill. There is bipartisan support for CCS because the fossil fuel industry sees it as a way to stay in the game and the unions believe that it will create jobs. This combination should garner enough votes to push it into the bill and get it passed, although the details around how CCS would be supported remain unclear. The infrastructure bill has very few real sources of income in it to offset the very high costs – something we will discuss on Sunday – and consequently giving a bigger tax break, through the 45Q program would create an even larger funding gap than we have today. The value/cost dynamic has to rise to get the activity that everyone is looking for and maybe that could be achieved by overlaying a carbon credit onto the program. Anyone exporting to Europe and concerned about the CBAM extending to natural gas, NGLs, chemicals, and polymers would likely consider CCS if they were eligible for 45Q and could also claim an offset on their exported products to neutralize the CBAM tax/fee.