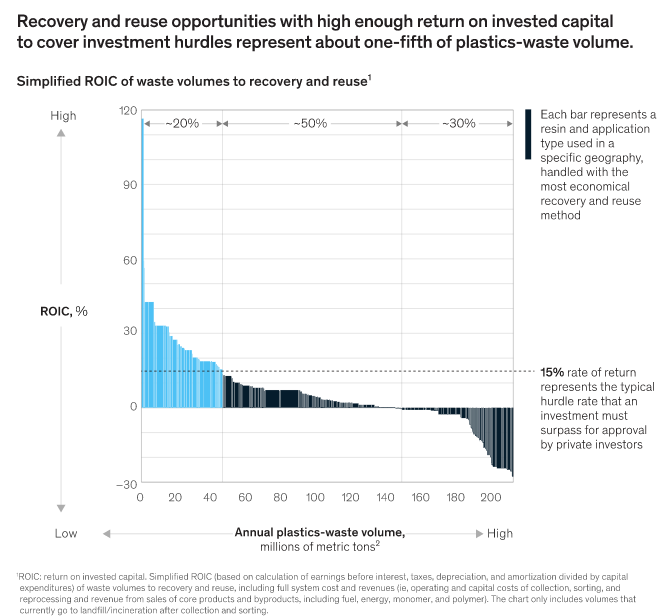

The McKinsey analysis is likely spot-on, as it is very difficult to get enough recycled polymer to produce a mechanically recycled stream that can be used in the highest value same use market. Solving for this is complicated by many factors, with too many stakeholders in many of the chains to make it work:

Plastics Recycling Is Mostly About Volume

Mar 4, 2022 1:42:27 PM / by Graham Copley posted in Recycling, Polyethylene, Plastics, PET, Mechanical Recycling, recycled polymer, HDPE, polymer, Plastics recycling

Pretty Charts Hide Very Complex ESG Problems

Sep 28, 2021 12:43:15 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Sustainability, Carbon, Emissions, Mechanical Recycling, recycled polymer, Gevo, feedstock, chemical recycling, polymer, biodegradable plastics, Origin, polymer demand, Covestro

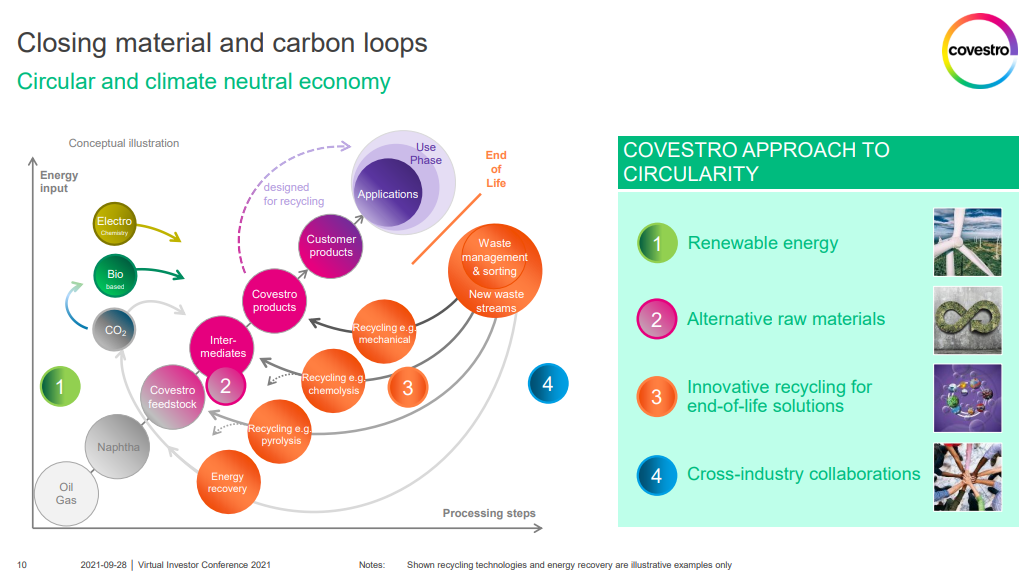

Companies are being encouraged/forced to produce climate plans by ever more focused shareholders many of whom only have a passing understanding of how some of the companies operate and how they might best set a course to lower emissions and otherwise be better stewards of the environment. The pretty graphic by Covestro below likely looks much better than the data and ambition behind it really are. This is not necessarily meant as a criticism of Covestro, but the company like many others is being challenged to explain a very complex, process, and engineering-heavy set of options to an audience not really qualified to understand them – pictures with circles are easier.

Some Recycling Ambitions Expect Too Much Of The Consumer

Jul 23, 2021 12:43:02 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastic Waste, Mechanical Recycling, chemical recycling, reusable plastics

The analysis behind the projections in Exhibit 6 in today's daily report, likely makes more assumptions than just the level of reusable plastics. To get the waste reduction projected, there will still need to be a step up in collection, sorting and recycling and it will all need to work to get the results desired. We are still concerned that these “high recycle” plans ask too much of an unwilling public, a slow to move average packager, and underfunded municipalities.

Chemical Recycling: An Easier Plastic Waste Than Recycling Story

Jul 20, 2021 2:23:38 PM / by Graham Copley posted in ESG, Recycling, Polymers, Plastic Waste, Pyrolysis, Mechanical Recycling, feedstock, chemical recycling, Agilyx, advanced recycling

The clear advantage of chemical recycling – as seen in the linked Agilyx headline – is that there are no issues with product cleanliness, etc., to get the material back into the cycle. As the polymers are essentially destroyed in the pyrolysis process and then reused as a feedstock in the traditional polymer production process, the rigors of sorting and cleaning for a mechanical recycling alternative are not needed. From a food contact perspective, chemical recycling is the easiest way to close the loop. What we are seeing in the headlines, however, is still “proof of concept” stuff and there remain plenty of challenges with logistics and/or proof of custody with the feedstocks that are flowing back to the ethylene unit, as well as how much recycling credit is appropriate, given that roughly half of the recycled feedstock does not end up as a polymer.

Advanced Recycling: Have We Misjudged You?

Jul 15, 2021 1:26:31 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Plastic Waste, Plastics, Mechanical Recycling, carbon footprint, carbon abatement, chemical recycling, zero waste

The ACC call for 30% recycling of plastics by 2030 emphasizes chemical recycling, and in our ESG and Climate report yesterday we talked about an alternate path for plastics, one that focuses on reducing waste rather than increasing recycling. The product standardization and consumer and municipality waste collection and sorting rigor that would be needed to maximize mechanical recycling are significantly harder to achieve than the changes that would be needed to dramatically increase chemical recycling – i.e. it may be easier and less expensive to get to zero waste than it is to get to maximum recycling. Maybe we are thinking about this wrong, but to change tacks from here the industry would need to demonstrate that plastic waste can be removed, at scale, and then convince the plastic buyers that the path is better. We discuss the possibility in more depth in yesterday’s report.

Recycling Confusion Continues: Brand Owners Could Struggle To Meet Goals

Jun 22, 2021 1:48:14 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastic Waste, Plastics, Mechanical Recycling, carbon footprint, polymer producers, chemical recycling

We want to focus on the following headline as it is both relevant and confusing:

More Recycling News. Hopefully More Recycling Action

May 27, 2021 1:48:57 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Polypropylene, Pyrolysis, Mechanical Recycling, LyondellBasell, Dow, unrecyclable polymer, sorting and cleaning, Nova, Closed Loop Partners, ethylene feed, PE

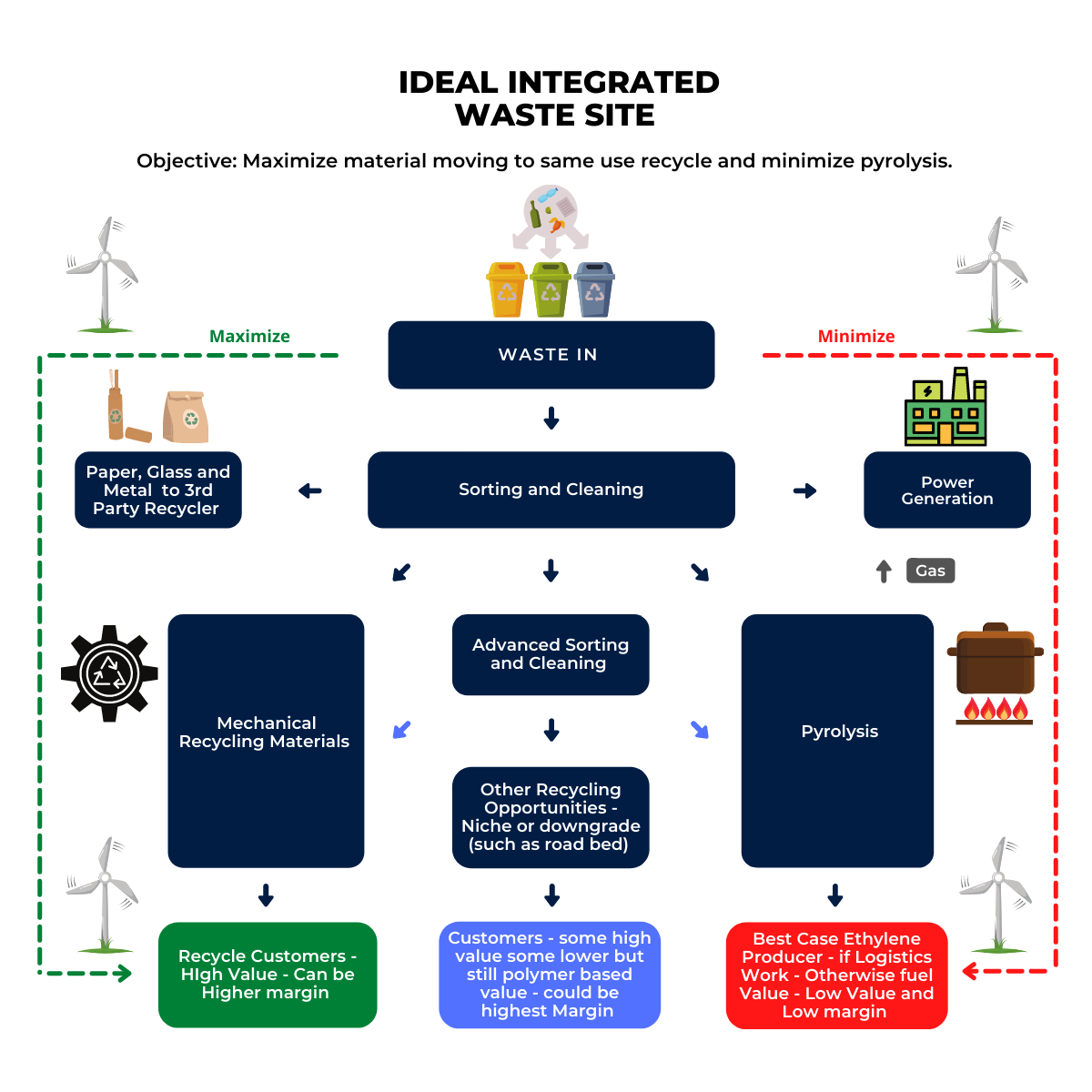

The Dow, LyondellBasell, Nova, Closed Loop Partners announcement yesterday is worth some thoughts. Closed Loop Partners is a PE company focused on funding recycling opportunities, but by its nature, it is relatively risk-averse as it has return goals to meet for its investors – to date its investments have been low-hanging fruit and niche in nature, but steps in the right direction nonetheless. The investment from the majors perhaps gives Closed Loop some wiggle room to look at projects that are less of a sure thing and maybe require a leap of faith on untested technologies or at least technologies untested at scale – primarily in sorting and identifying polymers and cleaning. We would still expect each project to be small, simply because access to the clean and easily sorted polyethylene and polypropylene in the US is limited by very poor standards of recycling and the vast proportion of unrecyclable polymer that ends up in a waste stream. If the group can find locations with significant supply, it might be wise to build pyrolysis at the same site to deal with everything that cannot be recycled. Our hope for this investment is that it is not simply an ESG PR opportunity for the polymer producers and that it does the following:

Pyrolysis Will Never Win If Consumers Are Willing To Pay For Recycled Plastics

Apr 30, 2021 1:46:22 PM / by Graham Copley posted in Recycling, Polymers, Plastic Waste, Plastics, Pyrolysis, Mechanical Recycling

Recycling is a fixed cost business – it does not vary with the price of oil or the price of natural gas – and the more willing potential customers are to pay on a fixed cost basis, to cover the collection, separation, cleaning, and re-pelletizing costs, the more recycled material will make it back into the cycle and not into landfill or pyrolysis. The pyrolysis technologies being discussed by the major polymer producers are a solution to the plastic WASTE problem, and they allow for a degree of recycling potentially, but they will never be able to bid waste polymer away from a mechanical recycling alternative if the buyer is willing to cover the costs. We have written extensively on these topics in our ESG and Climate reports and we would point readers back to Unwanted: Chemical Recycling – Necessary Now, Less So Later and the second section of True Blue: Not Green but Likely Good Enough.