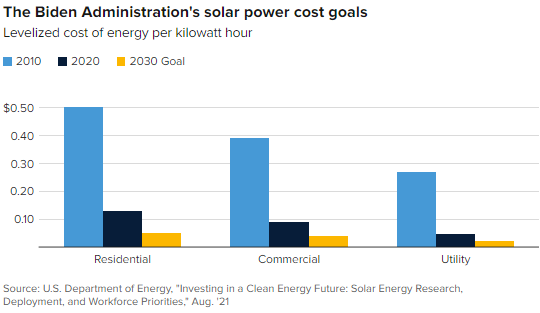

We are back on one of our pet topics today which is the reasonableness around some of the assumptions around the future cost of renewable power. We reference, work done by the US Department of Energy in the Exhibit below, and see two potential pitfalls with the assumptions around continuous improvement in solar, wind, and hydrogen costs, although there is a slight twist for hydrogen. The first is around the dynamics of learning curves. As the exhibit shows, in the early stages of any product development, there are huge leaps in cost improvements, driven by scale, better know-how, more efficient manufacturing, and in the case of solar power, both better processes for installation and some technology improvements. However, as you drive costs lower, the cost of raw materials becomes a much larger component of overall costs, and your ability to lower costs further can be overwhelmed by moves in material costs. Any inability to pass on the costs will result in economics that do not justify additional capital and you find yourselves in a commodity cycle. This is something that we have seen in basic polymers for decades, and no buyer of polyethylene today can claim that they are benefiting from a learning curve improvement. Closer to home for solar, we are seeing the same issue today in semiconductors – not enough margin to invest as everyone has been trying to push costs lower. The expectation in the DOE study and highlighted in the CNBC take on the study below is that annual solar installations in the US need to rise by 3-4X to meet some of the renewable power goals the Biden Administration is looking for by 2030, while similar growth is expected in other markets – the solar panel and other component makers have to be making good money to achieve this.

It's Hard To Bet On Deflation When You Are Dependent On Commodity Pricing

Aug 19, 2021 11:57:02 AM / by Graham Copley posted in ESG, Hydrogen, Climate Change, Sustainability, Renewable Power, Raw Materials, solar, copper, silver, wind, Lithium, solar energy, steel, basic polymers, semiconductors, renewable power goals, aluminum, EV batteries, rare earths

Lithium: A Commodity With Funding - Unlikely To End Well

Jul 2, 2021 12:10:22 PM / by Graham Copley posted in ESG, Sustainability, ESG Investing, copper, silver, batteries, energy transition, mining, Lithium, GM, auto market

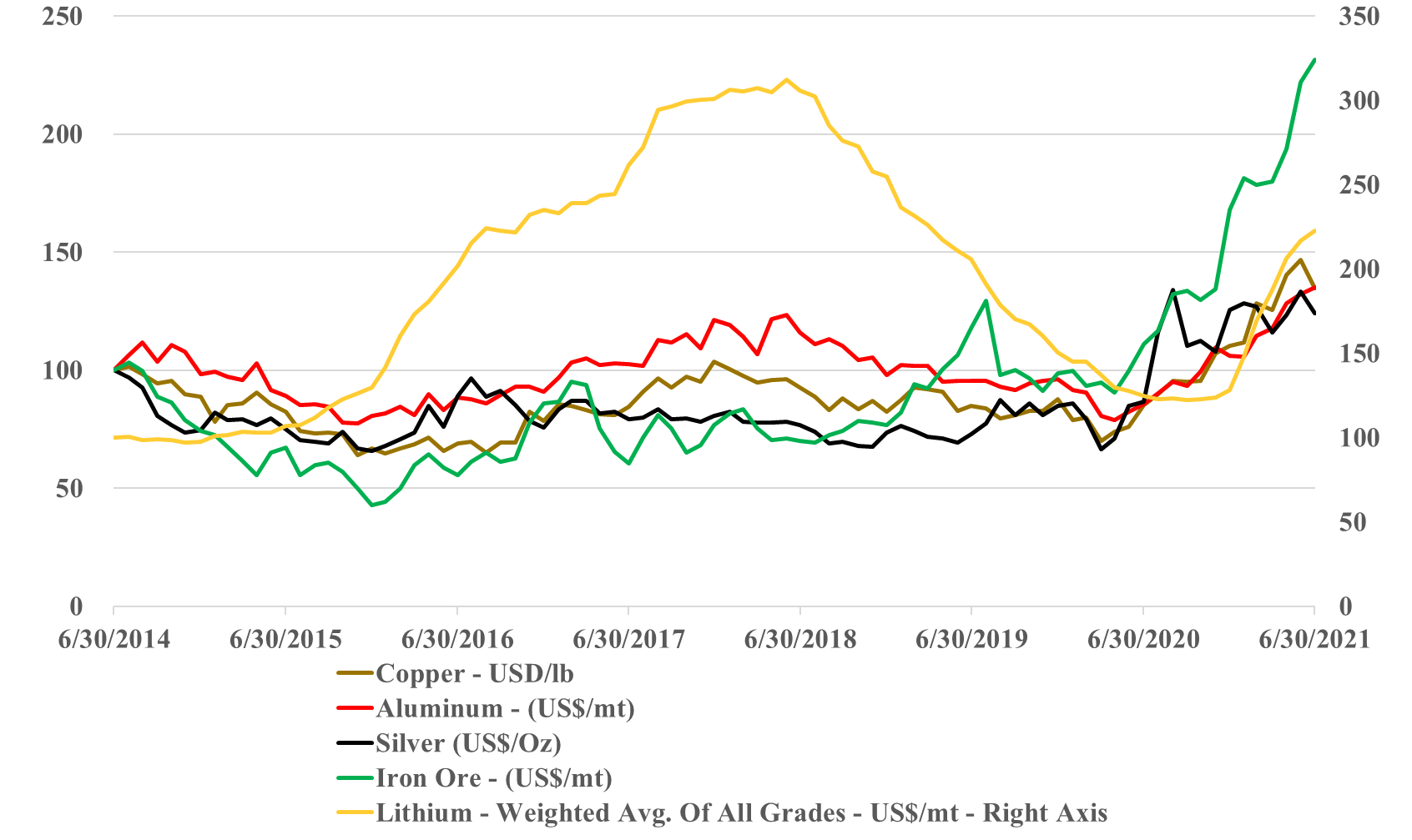

One of our concerns with the Lithium hype has been what we perceive to be very low barriers to entry – coupled with significant momentum from lithium ultimate end-users to encourage more production. If we look at the linked GM announcement, the company is making exactly the right strategic move. Providing some funding, but more importantly, high-level credibility for a new US-based project that could dwarf other US initiatives. While GM may have contracted all of the lithium volumes from this project, it is unlikely. GM’s interest, which should be aligned with all the other automakers is to ensure an ample to surplus availability of lithium long-term to keep pricing low. Investing a few million to give legitimacy to a new large project may have huge potential longer-term benefits if the capacity helps maintain a longer-term surplus market. While there may be some special sauce in the technology required to make the lithium grades for higher-end and higher density batteries, the bulk of the auto market is likely to trade range for cost in its battery decisions – and at the less expensive end, the lithium barriers are very low, with other brine-based projects under consideration and likely to find funding.

Solar: A Clear Example Of Potential Renewable Energy Inflation

Jun 17, 2021 1:32:30 PM / by Graham Copley posted in ESG, Hydrogen, Biofuels, Polymers, ESG Investing, Electric Vehicles, Raw Materials, LyondellBasell, Inflation, Gevo, solar, polysilicon, Wacker, copper, silver, Aemetis, renewable energy

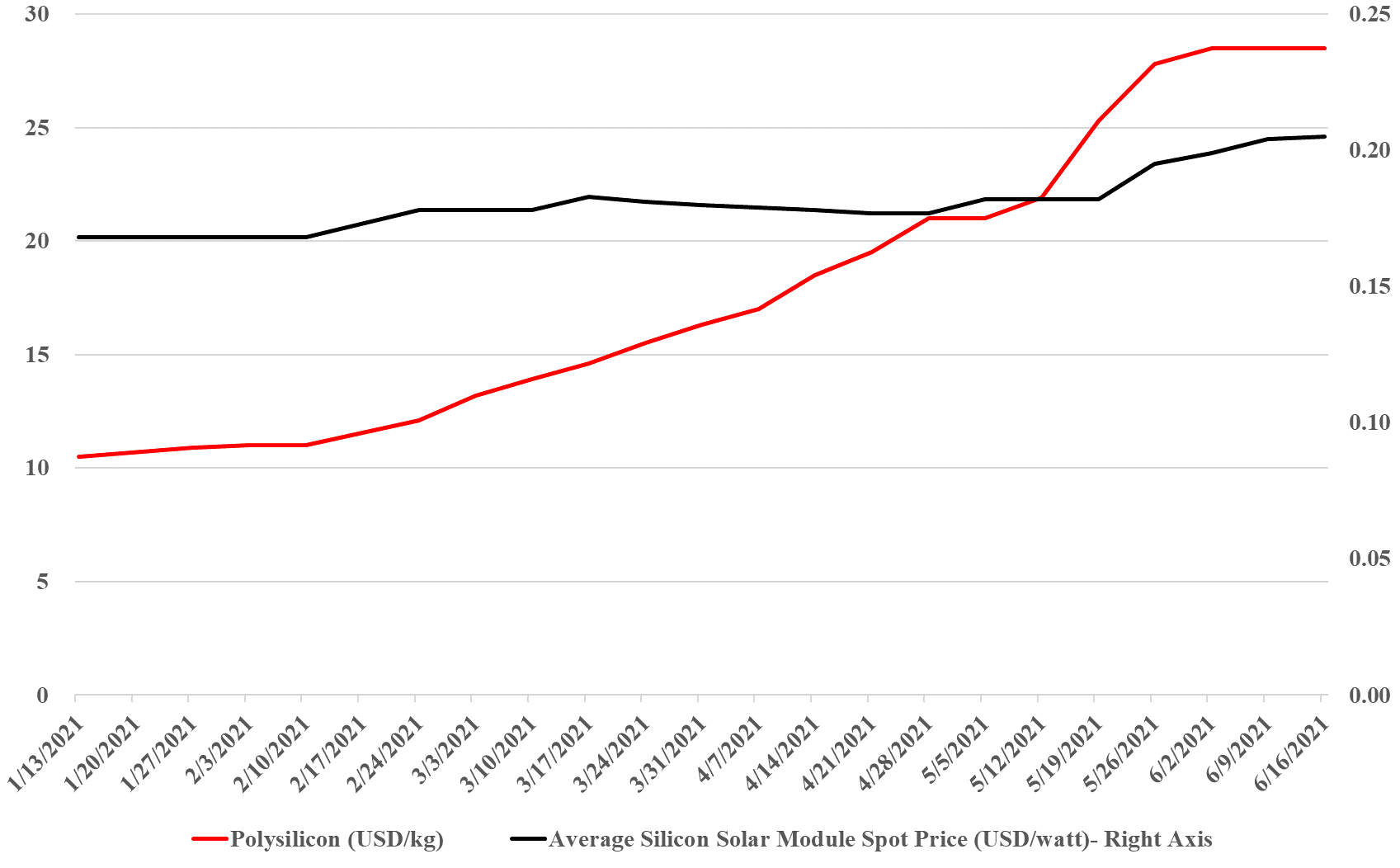

The exhibit below summarizes well one of the primary concerns that we have with some of the very ambitious goals for decarbonizing power grids, EV introduction, the further electrification of industry, and hydrogen. While the solar module price increase does not look that significant (yet), to put it in context, solar module prices have collapsed from over $1.80 per watt in 2010 to below $0.20 in 2020, and many of the expectations around cheap hydrogen require the cost to keep falling. The bigger concern is the polysilicon price, which is up 160% this year, good for the polysilicon producers like Wacker (see the headline here), but bad for the solar module producers, who are seeing major margin squeezes, especially given the rise in copper and silver as well this year. The raw material pressure should drive further increases in solar module pricing and while the higher margins for polysilicon will likely drive expansion investment, the metals are harder to call, given the ESG views on mining. We remain firmly of the view that raw material availability and price inflation, as well as module and wind turbine manufacturing capacity, will be the rate-determining constraint in terms of the growth in renewable power and this is why we question all of the near-term cheap power and cheap hydrogen goals that are being suggested by potential producers and government agencies.