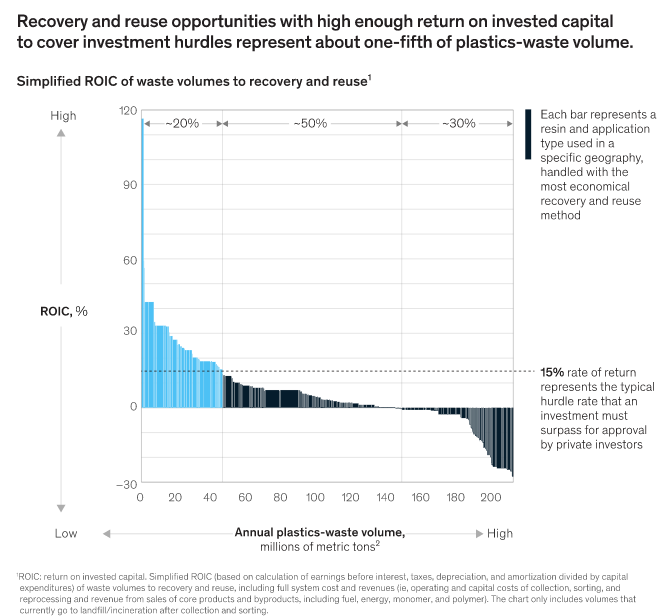

The McKinsey analysis is likely spot-on, as it is very difficult to get enough recycled polymer to produce a mechanically recycled stream that can be used in the highest value same use market. Solving for this is complicated by many factors, with too many stakeholders in many of the chains to make it work:

Plastics Recycling Is Mostly About Volume

Mar 4, 2022 1:42:27 PM / by Graham Copley posted in Recycling, Polyethylene, Plastics, PET, Mechanical Recycling, recycled polymer, HDPE, polymer, Plastics recycling

Plastic Waste Challenges Will Persist in 2022

Jan 5, 2022 2:25:33 PM / by Graham Copley posted in Plastic Waste, recycled polymer, advanced recycling

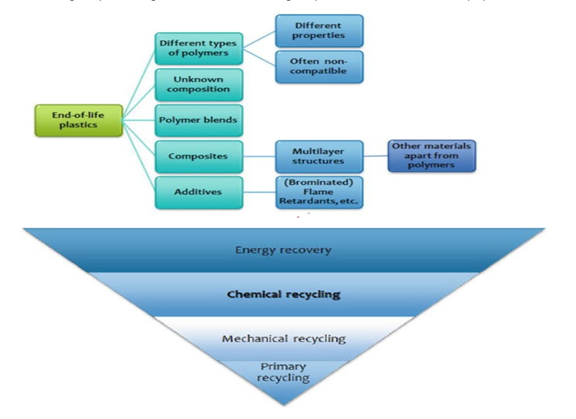

In our ESG and Climate report today we discuss whether plastics recycling and substitution from renewable polymers could take a breath in 2022, in part because of falling virgin polymer prices and in part because of cost inflation around new investments. Packagers, especially those who have been prescriptive around how much recycled/renewable material they plan to use by 2030, cannot afford for the pace of development to slow, but there is not much they can do about it. The polymer industry is pushing chemical recycling and has the balance sheet to keep pushing chemical recycling investment while the independent mechanical recyclers may be forced to pause. The packagers will need to endorse the use of chemically recycled material as the share of plastic waste moving in this direction increased. Complicating things further, there are two headlines today - linked here and here - that talk about plastic waste to hydrogen processes. These add to the Fulcrum Bioenergy facility starting up in Nevada and a second one planned for Indiana. These waste to hydrogen plants will take plastic waste out of the system (which is good) but there will be no ability to prove a chain of custody back into virgin resin as there is with chemical recycling. At some point, we believe that packagers will need to pivot and endorse both chemical recycling and low carbon polymers as an alternative to strict recycling targets. We would add the caveat with the waste to hydrogen processes that there is still a lot of learning curve to travel on large scale waste gasification – Fulcrum is a year late with its facility and not yet operational – the newcomers highlighted in the links are not guaranteed a smoother path.

Will Falling Polymer Prices Put The Brakes On Recycling Investment In 2022?

Jan 4, 2022 12:19:17 PM / by Graham Copley posted in recycled polymer, chemical recycling, biodegradable plastics, recycled waste

In our ESG and Climate Piece tomorrow we will look at the impact on plastic waste initiatives of falling virgin polymer prices. If recycling initiatives stall – especially the more expensive mechanical piece – it will likely add to concerns that packagers already have around whether they can get enough material to meet their public goals on recycled content. If it then also looks likely that new materials – renewable based on biodegradable - may be either late to market or more expensive than anticipated the door opens wider for the chemical recycling advocates and also for alternative materials. The chemical recyclers also need collection and sorting to improve, but the more complex/forgiving the facility, the less rigorous the sorting needs to be. Also, this route is somewhat agnostic to the price of virgin polymers as the output is competing with fuels and chemical feedstock values. For chemical recycling to be economic, the price of crude oil must remain high. For chemical recycling to get the lion’s share of recovered plastic waste the price of oil needs to be high and the price of virgin polymers low – discouraging mechanical recycling. While this may spur more chemical recycling, the net effect of low virgin polymer prices would overwhelm the benefit of better recycling economics for the majors – many of whom make up the bulk of the existing and planned chemical recycling capacity today. That said, the more plastic waste that ends up in chemical recycling, the less of an impact there will be on virgin plastic demand

Pretty Charts Hide Very Complex ESG Problems

Sep 28, 2021 12:43:15 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Sustainability, Carbon, Emissions, Mechanical Recycling, recycled polymer, Gevo, feedstock, chemical recycling, polymer, biodegradable plastics, Origin, polymer demand, Covestro

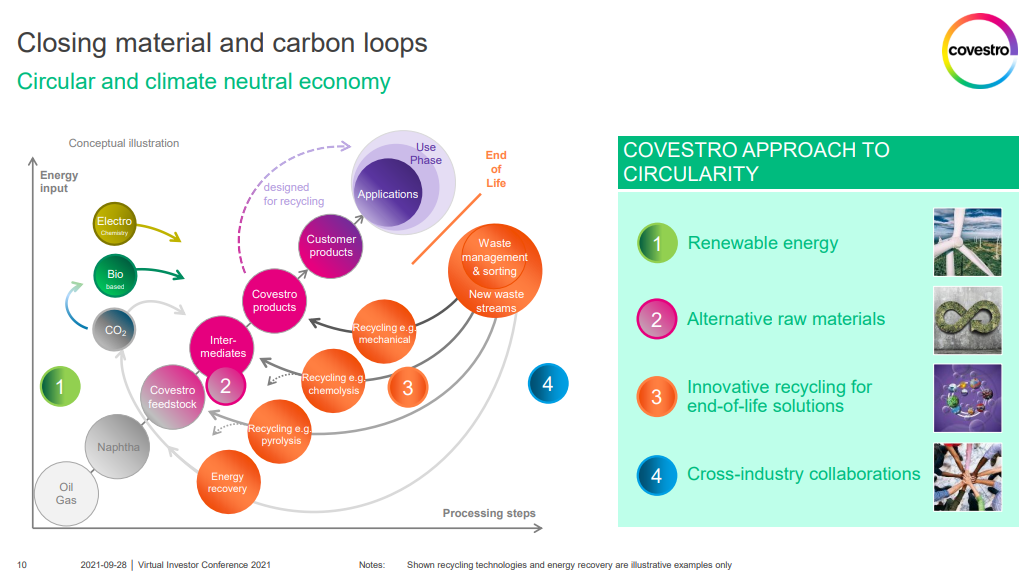

Companies are being encouraged/forced to produce climate plans by ever more focused shareholders many of whom only have a passing understanding of how some of the companies operate and how they might best set a course to lower emissions and otherwise be better stewards of the environment. The pretty graphic by Covestro below likely looks much better than the data and ambition behind it really are. This is not necessarily meant as a criticism of Covestro, but the company like many others is being challenged to explain a very complex, process, and engineering-heavy set of options to an audience not really qualified to understand them – pictures with circles are easier.

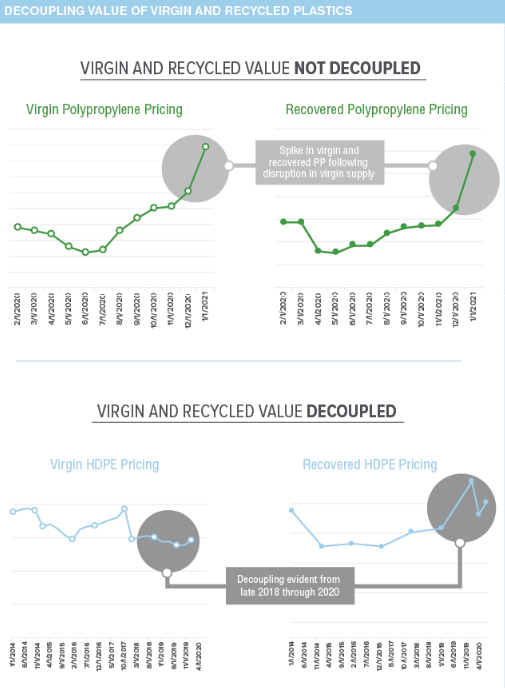

Consistent Supply Of Recycled Plastics Will Require Consistent & High Enough Pricing

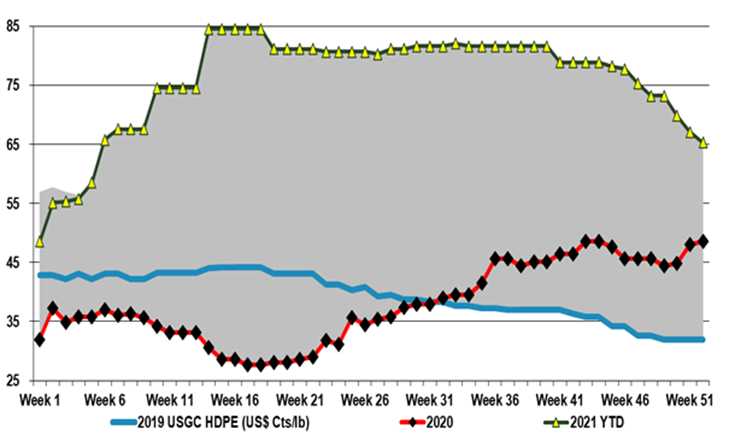

May 13, 2021 1:37:30 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Plastics, Polypropylene, recycled polymer, polymer pricing, hydrocarbon prices, virgin resins, supply and demand, raw materials inflation, LyondellBasell, Suez, polymer buyers

We talked a little about recycled polymer pricing in our ESG and Climate report yesterday. Recycled polymer pricing is rising relative to virgin polymer pricing (see chart below) and is likely to continue to rise unless hydrocarbon prices push virgin resins materially higher. Demand for recycled polymer is growing quickly and more quickly than supply, and we expect this to be reflected in an increased premium, barring more raw material inflation. Recycling is a fixed cost business – each step has a well-understood cost and companies are innovating to try and lower the cost of each step, but as so many different stakeholders are in the chain, it is a complex problem. One of the reasons why see the LyondellBasell/Suez venture works in The Netherlands is because Suez controls the waste in a region where recycling compliance at the household level is high. Despite this, it has taken a couple of years to get to the volumes needed to make the venture adequately profitable – mostly ensuring enough pure recycled polyethylene and polypropylene makes it to the facility. If polymer buyers are willing to cover the full cost of recycling in terms of the prices they are willing to pay, more material will become available – if LyondellBasell/Suez can demonstrate that they can make money when all the stars are aligned, it will likely encourage them to work with other municipalities in other parts of Europe (first) to see if they can replicate what they are doing now. In our view, all of the other advertised recycling programs are very small, very focused on niche applications, and don’t move the needle.