As we look at the news flow on recycling, we see many initiatives to collect, sort, and reuse polymers, whether for like-for-like applications, pyrolysis, or energy. What we do not see enough of, in our view, are initiatives to increase the pool of recycled plastics through packaging standardization or the elimination of compounds or colors that make recycling more challenging. Recycling can be improved by better collection and sorting methodologies and technologies. Still, the rate-limiting step will eventually be the pool of materials fit for recycling, and this is particularly important for like-for-like mechanical recycling. The ironic piece here is that the consumer staples and beverage companies call for higher recycled content and are primarily responsible for the amount of recyclable material in the market. If the packagers were to focus on sustainability rather than the unique look and feel of their packaging, we would see a material change in the volumes of recyclable polymers. This might come at the expense of some of the compounders, especially those with an extensive packaging component to their customer base, but it might also impact specific polymers and we would highlight polystyrene as a particularly vulnerable material as almost any application for which polystyrene is used today could be replaced with PET, polyethylene and/or polyethylene – all of which are larger volume polymers that are easier to recycle. The polystyrene industry is doing a good job of promoting recycling initiatives, but this may not be enough.

More Standardization In Packaging Is Needed To Boost Recycling

Apr 14, 2022 3:59:49 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Sustainability, packaging, standardization

It's Not Just Packaging That Needs To Be Recycled

Mar 30, 2022 11:55:43 AM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Sustainability, Plastic Waste, Plastics, Emissions, packaging, durables, carbon footprint, polymer, recycle, materials, Building Products, construction, life cycle, greenfield, building industry, recycled materials

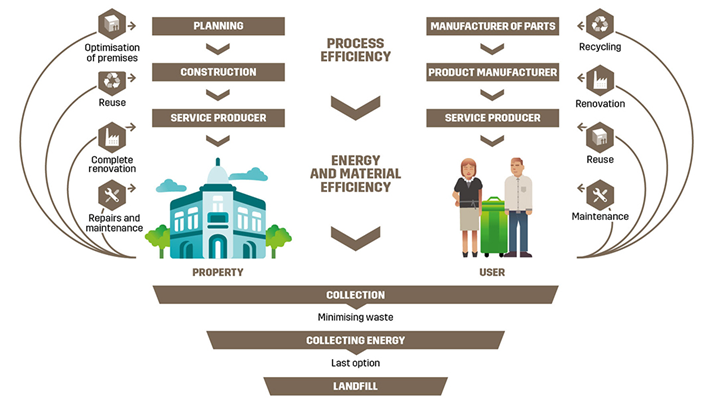

We tend to focus on recycling conventional plastic waste, but there are growing initiatives to look at the longer life cycle of durables and while this has mostly been focused on the automotive space, it is interesting to see the building industry looking at building life cycles. Many of the alternative use mechanical recycling initiatives are directed toward substituting building products such as concrete and wood and while this will help the construction sustainability story, the end of life cycle issue is less clear. The majority of commercial real-estate emissions are associated with operations (around 70%) and this is the greater focus for owners today, but the life cycle question is increasingly important for building tenants. In the UK for example there are redevelopment projects proactively advertising how much of the original building will be retained – i.e. not demolished and landfilled. Ultimately this might lead to lower demand for commercial building products where developers are looking at existing buildings, but it will not impact new greenfield builds unless you get a steep increase in recycled polymer use. The offset would likely be concrete as this is the high carbon footprint material that most are targeting. See more in today's ESG and Climate Report.

Green Polyethylene Will Be Important But Costs Will Matter

Mar 18, 2022 11:39:46 AM / by Graham Copley posted in ESG, Polymers, Climate Change, Sustainability, Polyethylene, Ethylene, packaging, ethanol, renewable polymers, renewables, Braskem, crude oil, sugar cane, sugarcane

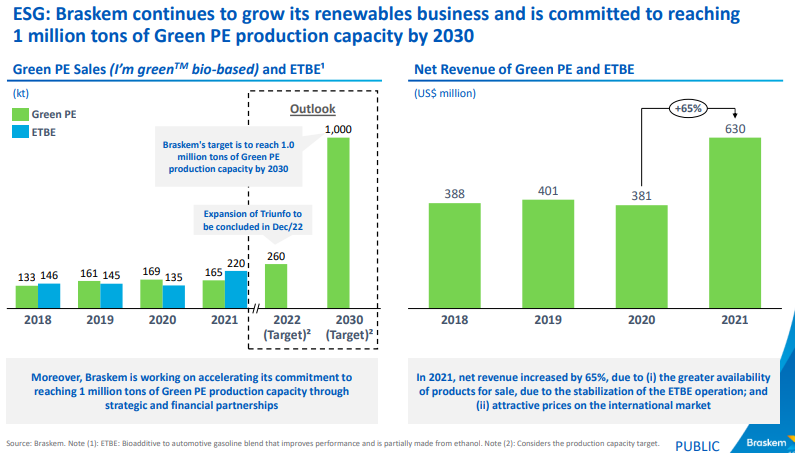

Braskem’s green polyethylene is an interesting niche opportunity, but we question how big the market might be for a product where you need the buyer to agree to prices that cover your costs – i.e. how many buyers will potentially pay up. In a $100 per barrel crude oil environment, polyethylene from sugar cane likely looks quite attractive, but probably less so in a $50 crude environment. Sugar cane-based ethanol has a cost advantage over corn-based ethanol, and one of the key questions for Braskem is how do you grow the business outside Brazil, where the barriers to entry for others are not much different. We do not doubt the demand potential for green polyethylene and other ethylene derivatives, but our concerns would be how to profitably grow the business, especially if there is a lower crude oil price backdrop. Today it is easy to make a bull case for oil – we do so above – but note that oil forecasting is not our strength and nor is it anyone else’s – based on hindsight. Paying a 20% premium over fossil fuel-based polymers may make sense for some packagers with meaningful ESG goals, but a 100% premium is likely unstable.

Packaging Waste Disposal May Not Mean Packaging Waste Recycled

Dec 17, 2021 1:59:37 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Pyrolysis, packaging, chemical recycling, renewables, climate, waste, carbon footprints, polymer recycling, waste disposal, recycled waste

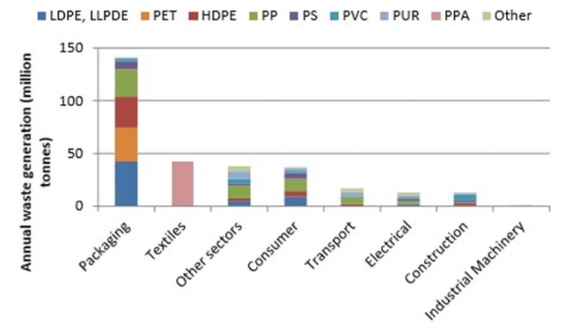

We have spent a lot of time over the last few weeks talking about polymer recycling and renewables and the chart below is another look at where plastic waste is coming from. Packaging is the big piece and it is also the area where customers, i.e. the packagers, are looking for the largest increase in the use of recycled materials quickly. As we noted in our ESG and Climate piece this week, increasing volumes of this packaging waste is moving into different use applications, such as building products and durables, and even more could potentially flow into chemical recycling – note that there are 7 headlines on chemical/advanced recycling in today's daily report. The packagers have little chance of meeting their near-term recycling content goals in our opinion, but they have zero chance if they do not accept chemical recycling as part of the mix. It will be important to accurately audit the chain of custody of chemical recycling to avoid double counting. The separate challenge with chemical recycling is the now increased focus on carbon footprints, as the pyrolysis process is energy-intensive, whether direct heat from burning fossil fuel or electric power-based heat.

Packagers Are Looking At Renewable Sources As Recycle Availability Is Limited

May 20, 2021 2:17:33 PM / by Graham Copley posted in Recycling, Biofuels, Polymers, PET, packaging, Gevo, Supply Chain, Butanol, Coca-Cola, packaging materials, biogradable polymers, Renewable Sources, hydrocarbons

The coverage of the IEA study continues with lots of opinions, which is a good sign as it means that the work is being taken seriously.