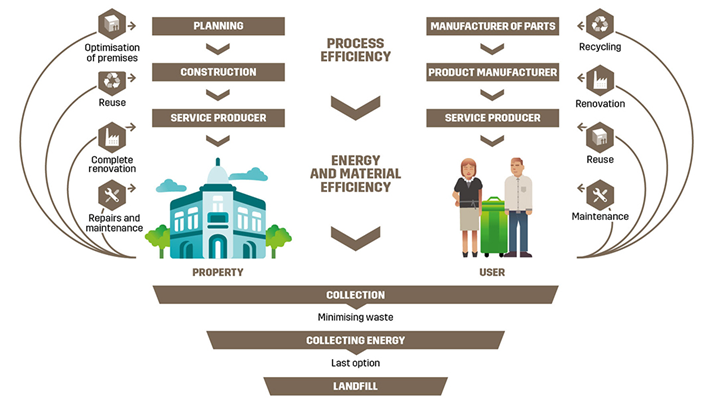

We tend to focus on recycling conventional plastic waste, but there are growing initiatives to look at the longer life cycle of durables and while this has mostly been focused on the automotive space, it is interesting to see the building industry looking at building life cycles. Many of the alternative use mechanical recycling initiatives are directed toward substituting building products such as concrete and wood and while this will help the construction sustainability story, the end of life cycle issue is less clear. The majority of commercial real-estate emissions are associated with operations (around 70%) and this is the greater focus for owners today, but the life cycle question is increasingly important for building tenants. In the UK for example there are redevelopment projects proactively advertising how much of the original building will be retained – i.e. not demolished and landfilled. Ultimately this might lead to lower demand for commercial building products where developers are looking at existing buildings, but it will not impact new greenfield builds unless you get a steep increase in recycled polymer use. The offset would likely be concrete as this is the high carbon footprint material that most are targeting. See more in today's ESG and Climate Report.

It's Not Just Packaging That Needs To Be Recycled

Mar 30, 2022 11:55:43 AM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Sustainability, Plastic Waste, Plastics, Emissions, packaging, durables, carbon footprint, polymer, recycle, materials, Building Products, construction, life cycle, greenfield, building industry, recycled materials

Plastic Waste Challenges Will Persist in 2022

Jan 5, 2022 2:25:33 PM / by Graham Copley posted in Plastic Waste, recycled polymer, advanced recycling

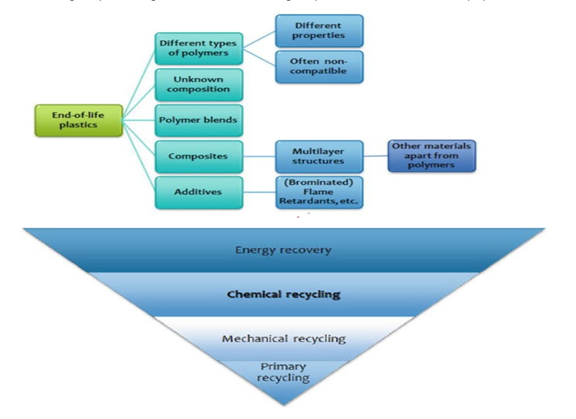

In our ESG and Climate report today we discuss whether plastics recycling and substitution from renewable polymers could take a breath in 2022, in part because of falling virgin polymer prices and in part because of cost inflation around new investments. Packagers, especially those who have been prescriptive around how much recycled/renewable material they plan to use by 2030, cannot afford for the pace of development to slow, but there is not much they can do about it. The polymer industry is pushing chemical recycling and has the balance sheet to keep pushing chemical recycling investment while the independent mechanical recyclers may be forced to pause. The packagers will need to endorse the use of chemically recycled material as the share of plastic waste moving in this direction increased. Complicating things further, there are two headlines today - linked here and here - that talk about plastic waste to hydrogen processes. These add to the Fulcrum Bioenergy facility starting up in Nevada and a second one planned for Indiana. These waste to hydrogen plants will take plastic waste out of the system (which is good) but there will be no ability to prove a chain of custody back into virgin resin as there is with chemical recycling. At some point, we believe that packagers will need to pivot and endorse both chemical recycling and low carbon polymers as an alternative to strict recycling targets. We would add the caveat with the waste to hydrogen processes that there is still a lot of learning curve to travel on large scale waste gasification – Fulcrum is a year late with its facility and not yet operational – the newcomers highlighted in the links are not guaranteed a smoother path.

Food Grade Plastic Proving Difficult To Recycle - Pyrolysis Is The Answer

Aug 26, 2021 12:40:00 PM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Plastic Waste, Plastics, Pyrolysis, chemical recycling, reuse, food packagers, food-grade polymer

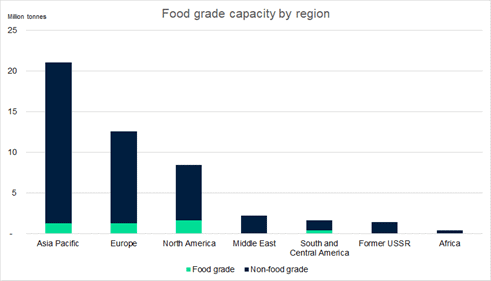

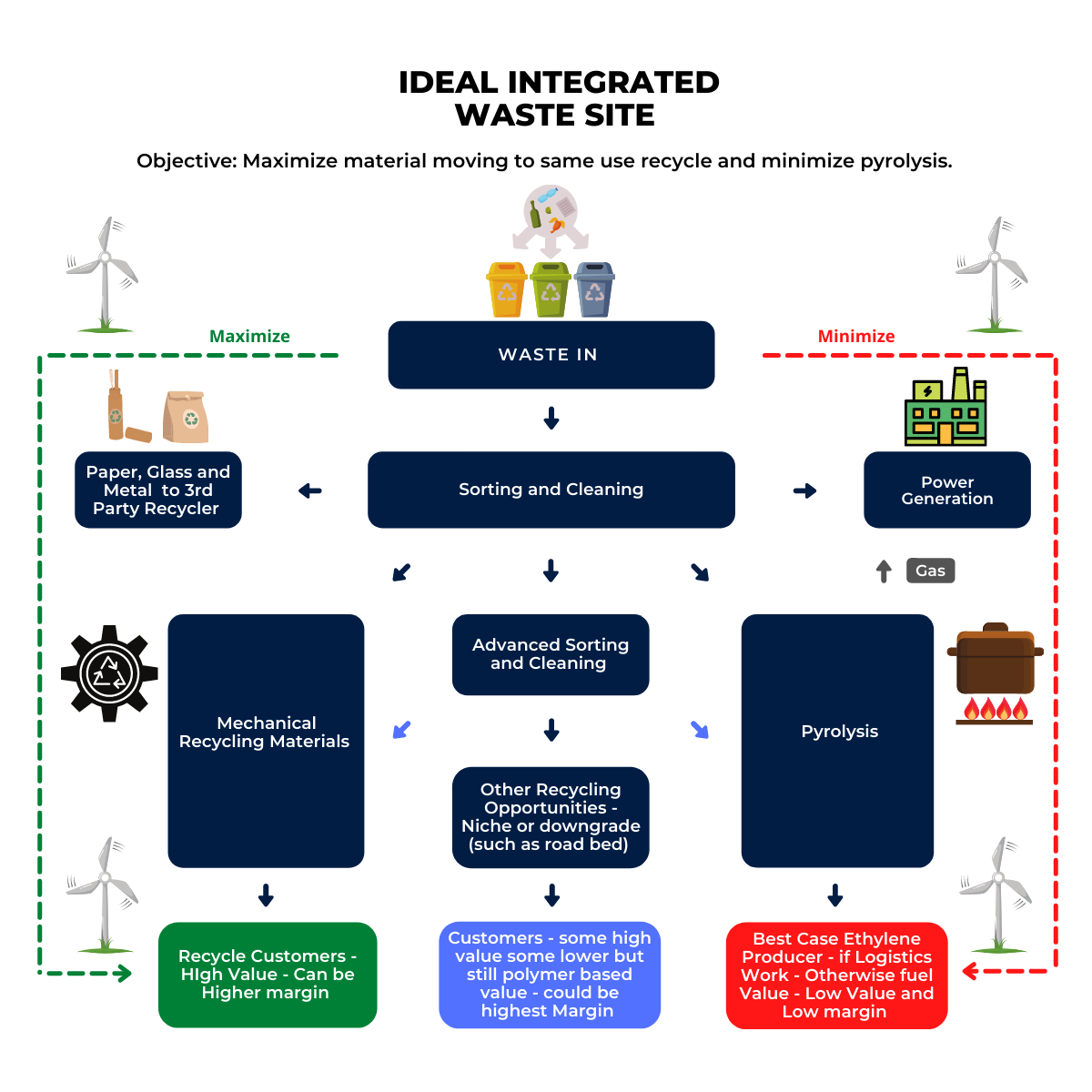

The exhibit below will come to many as a surprise, and it underlines one of the most significant challenges facing the recycling world. It is the food packagers who want the recycled content, but most food-grade polymer is not easily recycled (mechanically) once it has been in contact with food. Shrink-wrap for example is hard to collect and even harder to clean to a standard that is deemed safe and then hard to regrind because it is thin-film. This is where the polymer industry can really push the benefits of “advanced” chemical recycling as the process can take a mixed and not thoroughly cleaned stream of waste polymers with the recycling process itself (pyrolysis) destroying the contaminants and for the output that gets redirected back to ethylene units an additional shot at 1600-1700 Fahrenheit should remove any fears of contamination. You will not get the pound for pound recycle, but 35% is much better than the numbers suggested in the chart. Plus, in the process, you can destroy and reuse a great deal of plastic waste. See our ACC initiative write-up in yesterday’s ESG and Climate report.

100% Recycling: A Bold But Necessary Ambition For The ACC

Aug 25, 2021 1:33:16 PM / by Graham Copley posted in ESG, Recycling, Polymers, PVC, Plastic Waste, Plastics, chemical recycling, packaging polymers, ACC, plastics packaging, reuse, recycle, recover

The ACC goal of recovering 100% of packaging polymers is bold but likely necessary to show that its members are focused on a full solution, rather than some sort of halfway step. The goal is broken down as follows:

Will The Climate Frenzy Leave Plastic Waste Ignored For Now?

Aug 13, 2021 11:46:37 AM / by Graham Copley posted in ESG, Climate Change, Plastic Waste, Plastics, CCS, CO2, Emissions, Carbon Price, carbon abatement, climate, IPCC, Plastics producers, COP26, virgin plastic, plastic tax

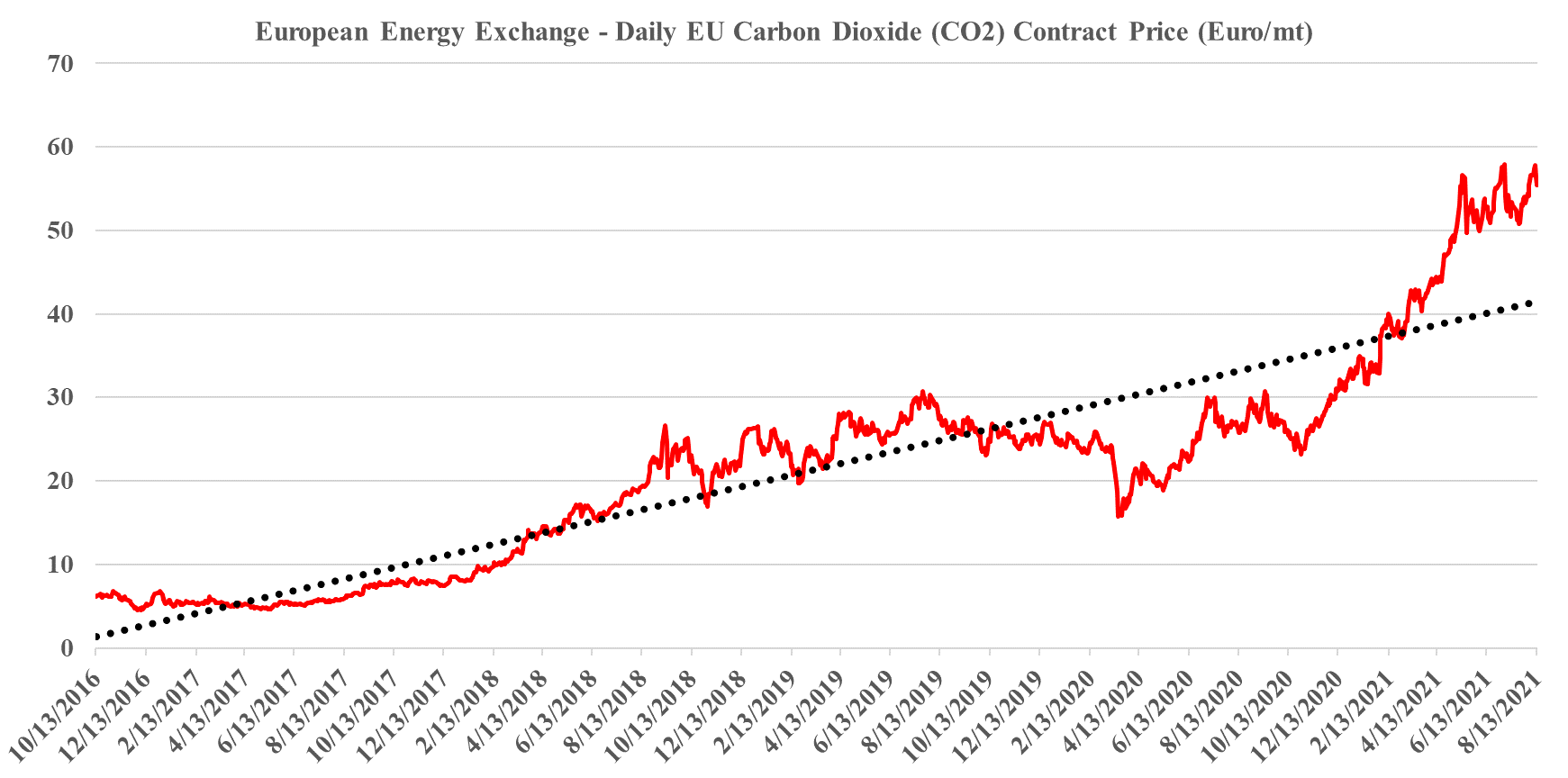

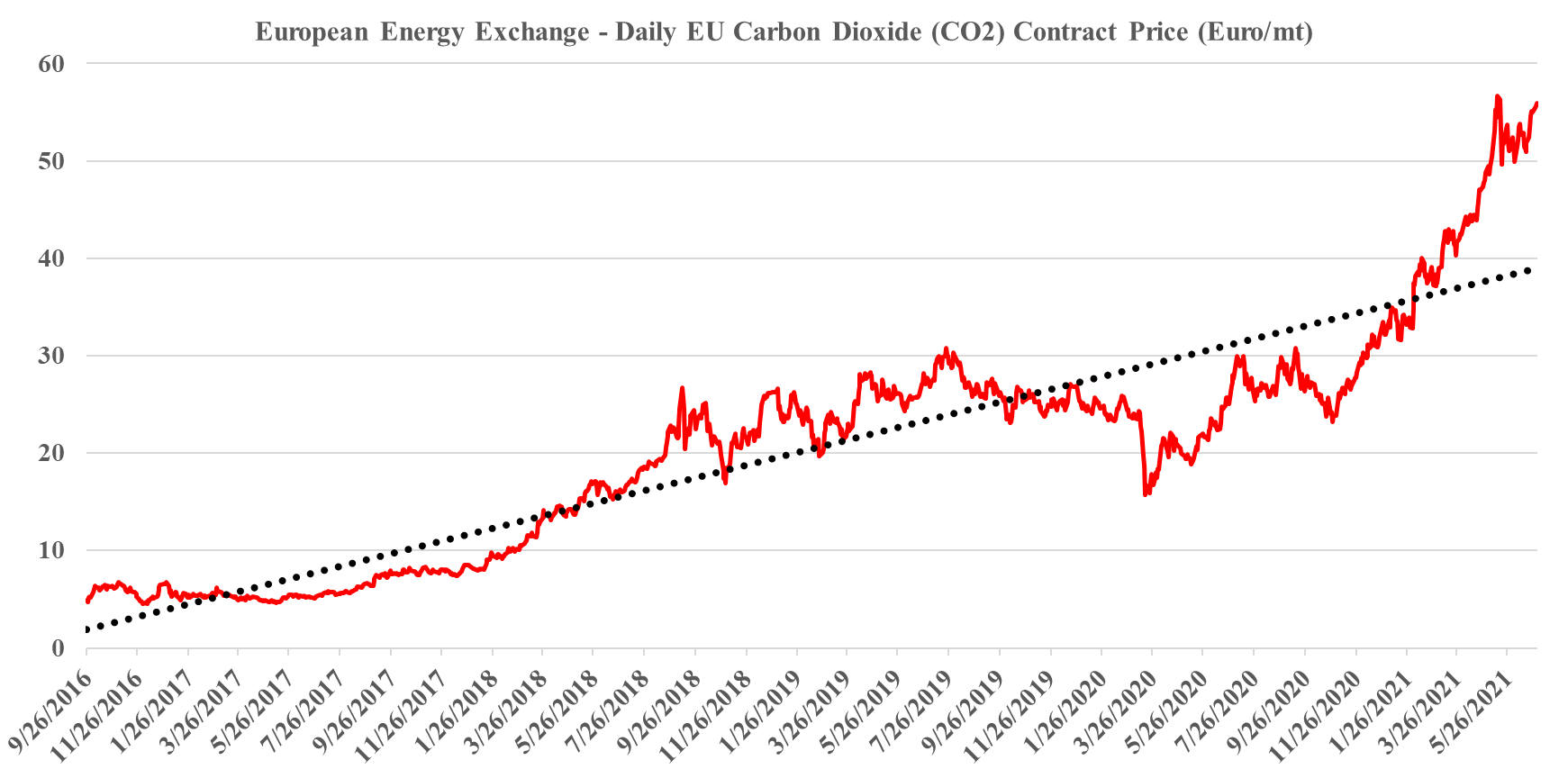

As we sift through the positioning for the upcoming COP26 meeting and the attention focusing report from the IPCC this week, it is a reasonable question to ask what this means for the plastic waste issue. If governments, lobbyists, and activists are likely to be more focused on climate change action over the next few years, which seems to be a reasonable conclusion, will there be the bandwidth for plastic waste? The plastic waste issue is less open to interpretation than the climate change issue and is a visible problem for all, but if governments need to prioritize where they spend their incremental dollar, and/or where they provide incentives of penalties, the climate is going to be pushed to the front of the line in our view. Plastics producers will have to deal with emissions, like any other industrial user of power and heat. The risk is that local governments, looking for revenue to support climate initiatives see taxing virgin plastic (or unrecycled plastic) as a way to both push plastic waste initiatives forward and raise revenue. Adding a plastic tax in the US to the superfund proposal in the infrastructure bill would be hitting the chemicals industry from two sides and would give bodies like the ACC far more grounds for pushback. For more on the IPCC analysis see our ESG & Climate Change report from this week.

Some Recycling Ambitions Expect Too Much Of The Consumer

Jul 23, 2021 12:43:02 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastic Waste, Mechanical Recycling, chemical recycling, reusable plastics

The analysis behind the projections in Exhibit 6 in today's daily report, likely makes more assumptions than just the level of reusable plastics. To get the waste reduction projected, there will still need to be a step up in collection, sorting and recycling and it will all need to work to get the results desired. We are still concerned that these “high recycle” plans ask too much of an unwilling public, a slow to move average packager, and underfunded municipalities.

Chemical Recycling: An Easier Plastic Waste Than Recycling Story

Jul 20, 2021 2:23:38 PM / by Graham Copley posted in ESG, Recycling, Polymers, Plastic Waste, Pyrolysis, Mechanical Recycling, feedstock, chemical recycling, Agilyx, advanced recycling

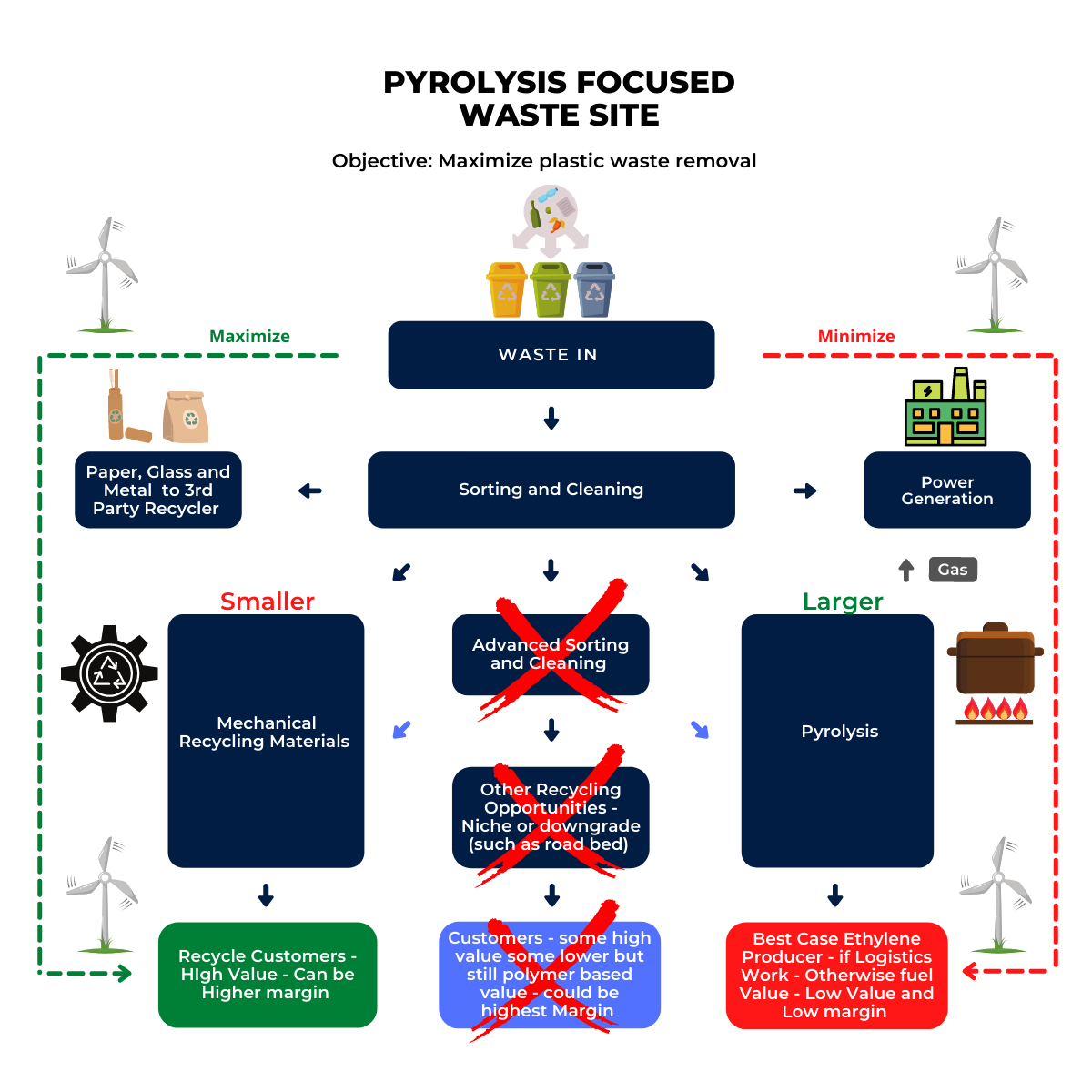

The clear advantage of chemical recycling – as seen in the linked Agilyx headline – is that there are no issues with product cleanliness, etc., to get the material back into the cycle. As the polymers are essentially destroyed in the pyrolysis process and then reused as a feedstock in the traditional polymer production process, the rigors of sorting and cleaning for a mechanical recycling alternative are not needed. From a food contact perspective, chemical recycling is the easiest way to close the loop. What we are seeing in the headlines, however, is still “proof of concept” stuff and there remain plenty of challenges with logistics and/or proof of custody with the feedstocks that are flowing back to the ethylene unit, as well as how much recycling credit is appropriate, given that roughly half of the recycled feedstock does not end up as a polymer.

Advanced Recycling: Have We Misjudged You?

Jul 15, 2021 1:26:31 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Plastic Waste, Plastics, Mechanical Recycling, carbon footprint, carbon abatement, chemical recycling, zero waste

The ACC call for 30% recycling of plastics by 2030 emphasizes chemical recycling, and in our ESG and Climate report yesterday we talked about an alternate path for plastics, one that focuses on reducing waste rather than increasing recycling. The product standardization and consumer and municipality waste collection and sorting rigor that would be needed to maximize mechanical recycling are significantly harder to achieve than the changes that would be needed to dramatically increase chemical recycling – i.e. it may be easier and less expensive to get to zero waste than it is to get to maximum recycling. Maybe we are thinking about this wrong, but to change tacks from here the industry would need to demonstrate that plastic waste can be removed, at scale, and then convince the plastic buyers that the path is better. We discuss the possibility in more depth in yesterday’s report.

Expected ESG Regulation Likely Good For Pure-Play Energy Transition Stocks

Jun 30, 2021 4:05:20 PM / by Graham Copley posted in ESG, Biofuels, Plastic Waste, CCS, Carbon, Dow, ESG Fund, solar, ESG investment, wind, European Carbon price, carbon emissions

The ESG investment shakeup could be one of the major events of this year, and as many of the headlines in our daily report suggest, there is a lot of work to be done, whether it is agreeing on a common set of measurement metrics – note the US and European differences discussed in one story – or the introduction of more empirical methods to judge whether what is labeled as an ESG investment fund is labeled correctly. There is also the issue of comparable disclosures, especially for companies in complex industries. It is interesting to note that in many analyses we see around carbon footprint or greenhouse gas emissions, and the potential routes to and cost of abatement, the chemical industry is omitted, except for ethanol and hydrogen. This is despite the industry accounting for 15% of the non-power emissions in the US industrial sector (similar in size to refineries). We believe that this is because the complexity of the industry makes it hard to model, and analysts choose to exclude it because they are not sure what they are doing.

Recycling Confusion Continues: Brand Owners Could Struggle To Meet Goals

Jun 22, 2021 1:48:14 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastic Waste, Plastics, Mechanical Recycling, carbon footprint, polymer producers, chemical recycling

We want to focus on the following headline as it is both relevant and confusing: