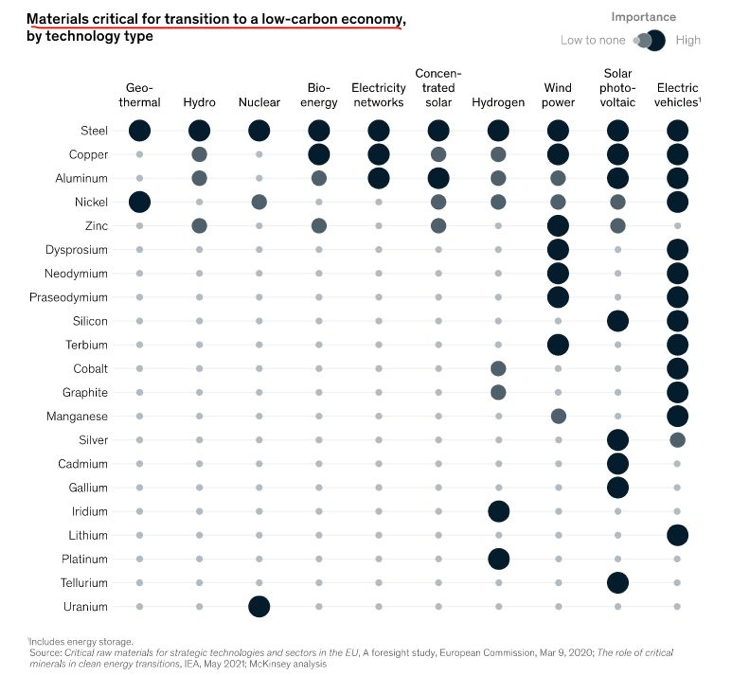

The materials chart in the exhibit below from today's daily report, is worth noting as it highlights all of the materials that are needed to advance the production of equipment required to drive renewable power production and demand. We would make one change to the chart in that lithium should also be added to the wind and solar categories to account for storage that needs to be built, although this could be done through hydrogen production or hydraulically, depending on location. One of our primary concerns concerning renewable power projections is the availability of some of these materials and we have written about the topic at length – most comprehensively in - 2022 – Policy Key, But Inflation Will Distract – Maybe Beneficially.

Another Illustration Of How Important Metals Are To Energy Transition

Jan 21, 2022 1:07:16 PM / by Graham Copley posted in ESG, Hydrogen, Sustainability, Renewable Power, Metals, Raw Materials, solar, renewable energy, wind, energy transition, Lithium, climate, advanced recycling, materials, low carbon, material shortages, low carbon economy, renewable power production

Plastic Waste Challenges Will Persist in 2022

Jan 5, 2022 2:25:33 PM / by Graham Copley posted in Plastic Waste, recycled polymer, advanced recycling

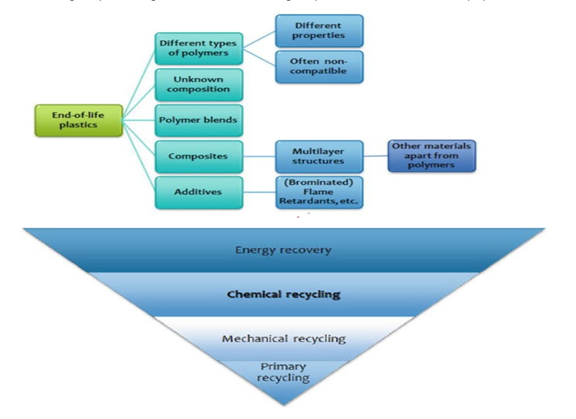

In our ESG and Climate report today we discuss whether plastics recycling and substitution from renewable polymers could take a breath in 2022, in part because of falling virgin polymer prices and in part because of cost inflation around new investments. Packagers, especially those who have been prescriptive around how much recycled/renewable material they plan to use by 2030, cannot afford for the pace of development to slow, but there is not much they can do about it. The polymer industry is pushing chemical recycling and has the balance sheet to keep pushing chemical recycling investment while the independent mechanical recyclers may be forced to pause. The packagers will need to endorse the use of chemically recycled material as the share of plastic waste moving in this direction increased. Complicating things further, there are two headlines today - linked here and here - that talk about plastic waste to hydrogen processes. These add to the Fulcrum Bioenergy facility starting up in Nevada and a second one planned for Indiana. These waste to hydrogen plants will take plastic waste out of the system (which is good) but there will be no ability to prove a chain of custody back into virgin resin as there is with chemical recycling. At some point, we believe that packagers will need to pivot and endorse both chemical recycling and low carbon polymers as an alternative to strict recycling targets. We would add the caveat with the waste to hydrogen processes that there is still a lot of learning curve to travel on large scale waste gasification – Fulcrum is a year late with its facility and not yet operational – the newcomers highlighted in the links are not guaranteed a smoother path.

Chemical Recycling: An Easier Plastic Waste Than Recycling Story

Jul 20, 2021 2:23:38 PM / by Graham Copley posted in ESG, Recycling, Polymers, Plastic Waste, Pyrolysis, Mechanical Recycling, feedstock, chemical recycling, Agilyx, advanced recycling

The clear advantage of chemical recycling – as seen in the linked Agilyx headline – is that there are no issues with product cleanliness, etc., to get the material back into the cycle. As the polymers are essentially destroyed in the pyrolysis process and then reused as a feedstock in the traditional polymer production process, the rigors of sorting and cleaning for a mechanical recycling alternative are not needed. From a food contact perspective, chemical recycling is the easiest way to close the loop. What we are seeing in the headlines, however, is still “proof of concept” stuff and there remain plenty of challenges with logistics and/or proof of custody with the feedstocks that are flowing back to the ethylene unit, as well as how much recycling credit is appropriate, given that roughly half of the recycled feedstock does not end up as a polymer.