We don’t want to throw cold water on a very HOT idea, but the BASF, SABIC, Linde announcement of collaboration on electric furnaces for ethylene production is not the first that we have seen, as both Dow and Shell have stated that they are looking at similar ideas. As an “endgame” objective this is interesting, as it would remove the need for natural gas fuel and greatly reduce emissions, but despite the claims in the release, this is an interesting pilot project at best today. It is a credible process, and the companies have likely achieved ethylene production this way on a lab scale. It is possible to get significantly higher temperatures today through electric power than the 800c (1500f) suggested in the article. Some plasma jet technology can achieve temperatures in the 1000s of degrees centigrade, but the power consumption is extremely high, and it is worth noting that the press release does not mention the possible power requirements to get to a metric ton of ethylene. Modern ethylene units produce a million tons a year (or more) – which is around 2 metric tons per minute. The better technologies involve raising the feedstocks to very high temperatures very quickly (measured in fractions of a second). The partners talk about achieving electric power-based ethylene at scale. This is a lofty goal. Should they succeed, not only would ethylene plants require significant retrofitting at the front end at very high capital cost, but the power requirements would be enormous, putting even greater strain on global and regional renewable power ambitions, that already looks hard to achieve, given all of the competing needs. We would want to ask two questions:

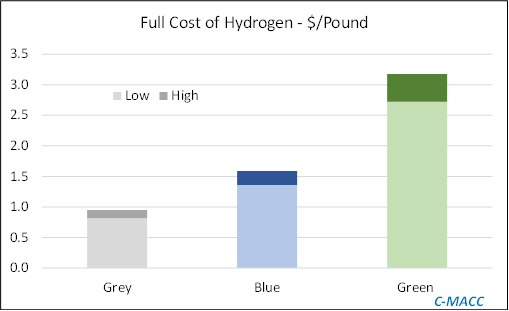

- Are you better off making hydrogen and using hydrogen as a furnace fuel in a traditional and well-practiced ethylene process – this would likely mean much lower capital refit costs?

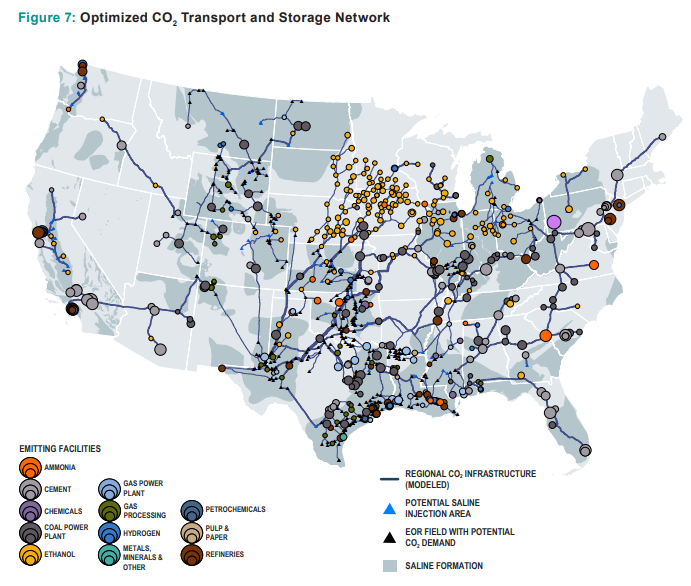

- Are you better off still just capturing and sequestering the CO2 from existing facilities?

Photo by Linde Engineering. The ethylene furnaces are in the background to the right of the picture

With many of these “cleaner” objectives and theoretical technologies, there may be other more practical workarounds, and if not they still probably do not make sense until there is such an abundance of renewable power that the incremental cost of power is very low for 95% of the time.