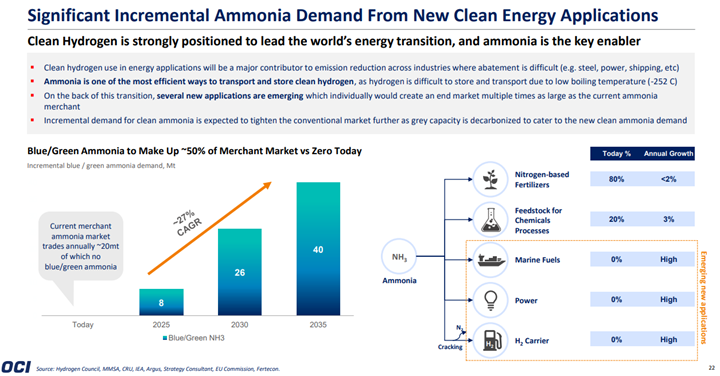

There is the potential for the ammonia thirst (please don’t drink it) to surpass opportunities to build cost-effective capacity for the medium term. Consequently, the shortages we see today could extend and become more severe. Co-firing coal-based power facilities in Asia is one of the more obvious ways to start decarbonizing a predominantly coal-based power region. The experiments in Japan, if successful, will drive a step-change in demand for blue or green ammonia, and this should drive much more new capacity than we have seen announced to date. The power-based demand comes on top of expected growth in fertilizer-driven demand and a possible rise as a shipping fuel. The issue for investors is that green ammonia at scale is economically challenging, especially with the recent shortfalls in renewable power generating plans and what now looks like rising power costs for a while. Blue ammonia is much easier to think about at scale, but we are still hamstrung by expensive carbon capture costs and a lack of incentives – either in terms of tax breaks or taxes or in terms of a customer willing to pay more, to get most ideas and plans past the “wouldn’t it be nice” phase. In the meantime, as indicated above, installed ammonia capacity is making abnormal returns.

Shortages: Ammonia, Affordable Ethanol, & Renewable Power In The Right Places

May 12, 2022 2:01:48 PM / by Graham Copley posted in Polyethylene, Ethylene, Renewable Power, Ammonia, ethanol, blue ammonia, Braskem, fertilizer, reshoring, green ammonia, sugar, green polyethelyne

Green Polyethylene Will Be Important But Costs Will Matter

Mar 18, 2022 11:39:46 AM / by Graham Copley posted in ESG, Polymers, Climate Change, Sustainability, Polyethylene, Ethylene, packaging, ethanol, renewable polymers, renewables, Braskem, crude oil, sugar cane, sugarcane

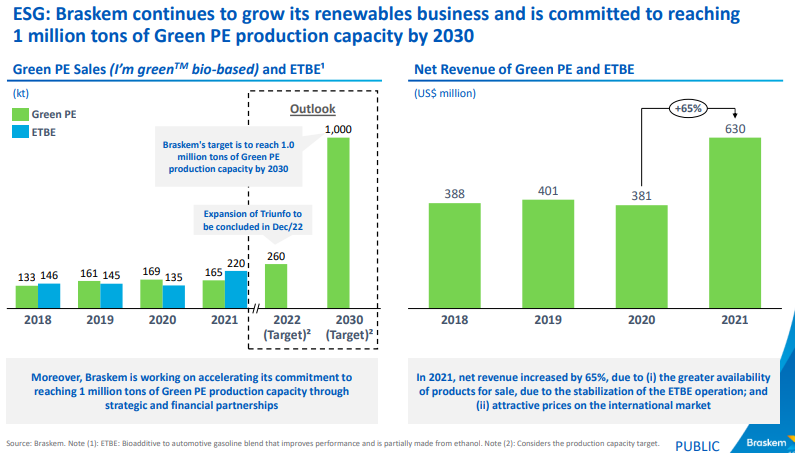

Braskem’s green polyethylene is an interesting niche opportunity, but we question how big the market might be for a product where you need the buyer to agree to prices that cover your costs – i.e. how many buyers will potentially pay up. In a $100 per barrel crude oil environment, polyethylene from sugar cane likely looks quite attractive, but probably less so in a $50 crude environment. Sugar cane-based ethanol has a cost advantage over corn-based ethanol, and one of the key questions for Braskem is how do you grow the business outside Brazil, where the barriers to entry for others are not much different. We do not doubt the demand potential for green polyethylene and other ethylene derivatives, but our concerns would be how to profitably grow the business, especially if there is a lower crude oil price backdrop. Today it is easy to make a bull case for oil – we do so above – but note that oil forecasting is not our strength and nor is it anyone else’s – based on hindsight. Paying a 20% premium over fossil fuel-based polymers may make sense for some packagers with meaningful ESG goals, but a 100% premium is likely unstable.

Plastics Recycling Is Mostly About Volume

Mar 4, 2022 1:42:27 PM / by Graham Copley posted in Recycling, Polyethylene, Plastics, PET, Mechanical Recycling, recycled polymer, HDPE, polymer, Plastics recycling

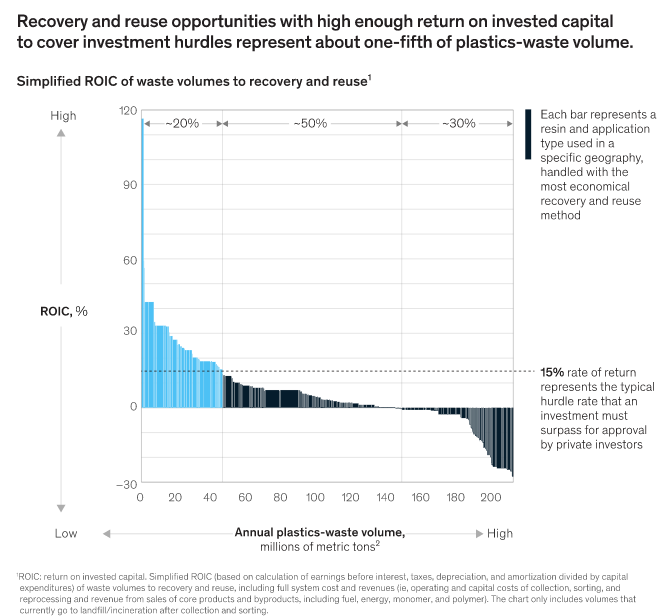

The McKinsey analysis is likely spot-on, as it is very difficult to get enough recycled polymer to produce a mechanically recycled stream that can be used in the highest value same use market. Solving for this is complicated by many factors, with too many stakeholders in many of the chains to make it work:

Carbon Footprints Matter, For Polymers And LNG

Nov 18, 2021 1:55:23 PM / by Graham Copley posted in ESG, Hydrogen, Recycling, Polymers, LNG, Polyethylene, CCS, Ethylene, decarbonization, HDPE, carbon abatement, ethane, naphtha, climate, carbon footprints, recycled polymers, virgin polymers, fuel, Freeport LNG

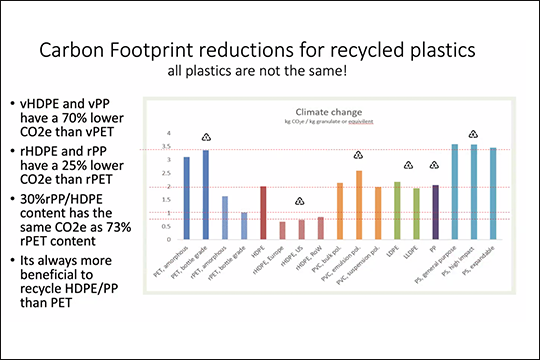

It is interesting to watch the pivot between recycled versus virgin polymer to the carbon footprint of the various options as outlined in the chart below. We are assuming that the numbers in the chart are averages as there is a sizeable range for everything. As we note in today's daily report, ethylene feedstock will impact the carbon footprint of ethylene and consequently, the footprint of polyethylene – HDPE made from ethane based ethylene in the US where the ethylene producer is recycling hydrogen back into the furnaces, will have a much lower carbon footprint than HDPE made from naphtha based ethylene in Europe, for example. On the recycling side, there will also be a range based on transportation costs for collection and sorting and then distribution to a customer.

Dow And Air Products Have Got The Ball Rolling, But How Fast?

Oct 21, 2021 1:54:22 PM / by Graham Copley posted in ESG, Hydrogen, Sustainability, Polyethylene, Blue Hydrogen, Air Products, decarbonization, Dow, climate, low carbon polyethylene

The Dow chart below was included in the presentation around the Canada project and repeated today in the earnings call. We have talked about the Canada project at length as well as the more recently announced Air Products blue hydrogen project in the US. The more interesting debate from here is what will happen next. Are Dow’s and Air Product’s phones ringing off the hooks with potential customers saying “we want some of that”, or is it quieter? We suspect that the phones are ringing and ringing a lot. Perhaps because people genuinely want the low carbon polyethylene or hydrogen, but also perhaps because users of polyethylene and hydrogen are likely obligated to find out more so that they can explore both the opportunities of buying from Dow or Air Products, or evaluating what their alternatives might be. We suspect that a surge in genuine customer interest is likely, good for both Dow and Air Products, but also good for others either considering decarbonizing projects or offering a carbon-free alternative already. See our ESG and Climate piece from yesterday for more on this.

More Recycling News. Hopefully More Recycling Action

May 27, 2021 1:48:57 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Polypropylene, Pyrolysis, Mechanical Recycling, LyondellBasell, Dow, unrecyclable polymer, sorting and cleaning, Nova, Closed Loop Partners, ethylene feed, PE

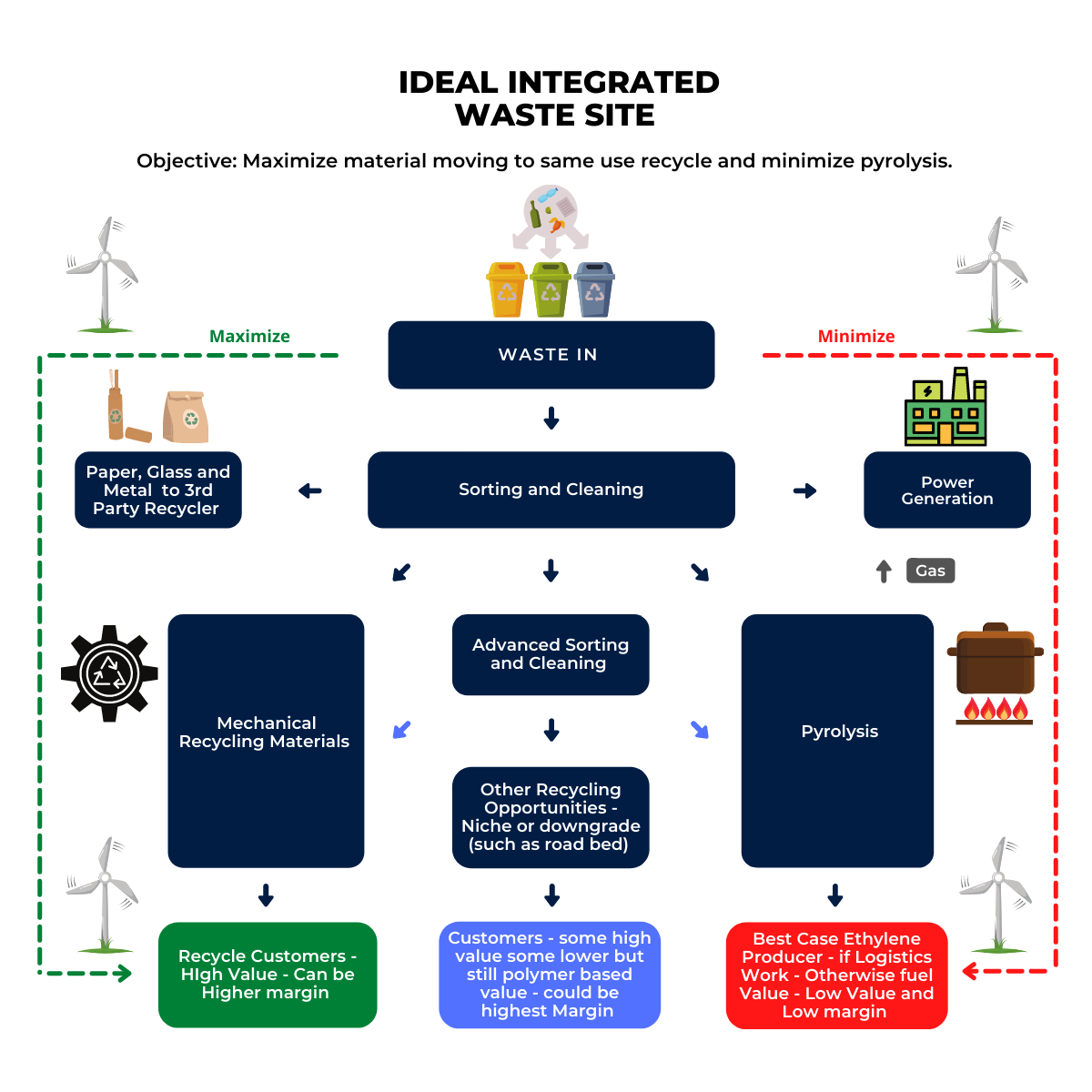

The Dow, LyondellBasell, Nova, Closed Loop Partners announcement yesterday is worth some thoughts. Closed Loop Partners is a PE company focused on funding recycling opportunities, but by its nature, it is relatively risk-averse as it has return goals to meet for its investors – to date its investments have been low-hanging fruit and niche in nature, but steps in the right direction nonetheless. The investment from the majors perhaps gives Closed Loop some wiggle room to look at projects that are less of a sure thing and maybe require a leap of faith on untested technologies or at least technologies untested at scale – primarily in sorting and identifying polymers and cleaning. We would still expect each project to be small, simply because access to the clean and easily sorted polyethylene and polypropylene in the US is limited by very poor standards of recycling and the vast proportion of unrecyclable polymer that ends up in a waste stream. If the group can find locations with significant supply, it might be wise to build pyrolysis at the same site to deal with everything that cannot be recycled. Our hope for this investment is that it is not simply an ESG PR opportunity for the polymer producers and that it does the following:

Consistent Supply Of Recycled Plastics Will Require Consistent & High Enough Pricing

May 13, 2021 1:37:30 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Plastics, Polypropylene, recycled polymer, polymer pricing, hydrocarbon prices, virgin resins, supply and demand, raw materials inflation, LyondellBasell, Suez, polymer buyers

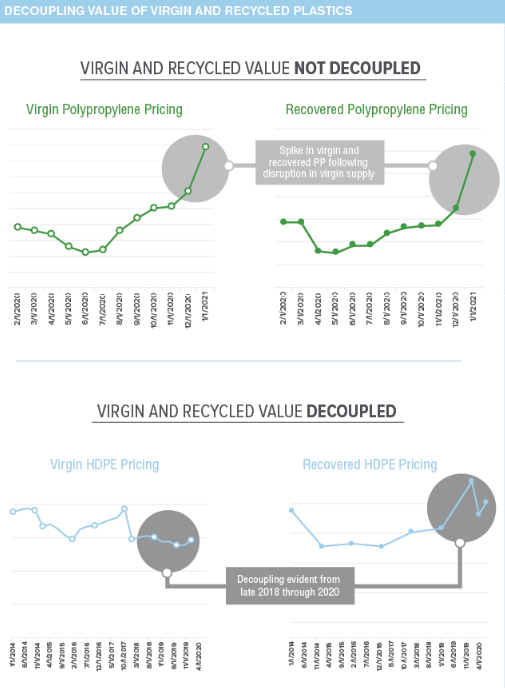

We talked a little about recycled polymer pricing in our ESG and Climate report yesterday. Recycled polymer pricing is rising relative to virgin polymer pricing (see chart below) and is likely to continue to rise unless hydrocarbon prices push virgin resins materially higher. Demand for recycled polymer is growing quickly and more quickly than supply, and we expect this to be reflected in an increased premium, barring more raw material inflation. Recycling is a fixed cost business – each step has a well-understood cost and companies are innovating to try and lower the cost of each step, but as so many different stakeholders are in the chain, it is a complex problem. One of the reasons why see the LyondellBasell/Suez venture works in The Netherlands is because Suez controls the waste in a region where recycling compliance at the household level is high. Despite this, it has taken a couple of years to get to the volumes needed to make the venture adequately profitable – mostly ensuring enough pure recycled polyethylene and polypropylene makes it to the facility. If polymer buyers are willing to cover the full cost of recycling in terms of the prices they are willing to pay, more material will become available – if LyondellBasell/Suez can demonstrate that they can make money when all the stars are aligned, it will likely encourage them to work with other municipalities in other parts of Europe (first) to see if they can replicate what they are doing now. In our view, all of the other advertised recycling programs are very small, very focused on niche applications, and don’t move the needle.