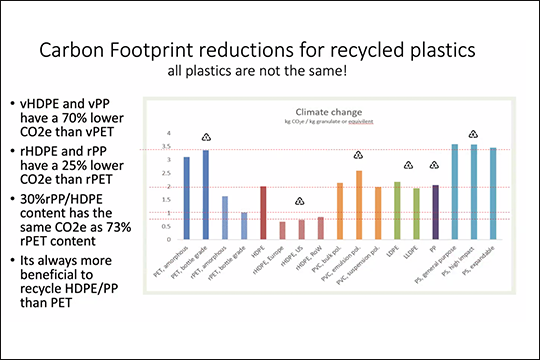

It is interesting to watch the pivot between recycled versus virgin polymer to the carbon footprint of the various options as outlined in the chart below. We are assuming that the numbers in the chart are averages as there is a sizeable range for everything. As we note in today's daily report, ethylene feedstock will impact the carbon footprint of ethylene and consequently, the footprint of polyethylene – HDPE made from ethane based ethylene in the US where the ethylene producer is recycling hydrogen back into the furnaces, will have a much lower carbon footprint than HDPE made from naphtha based ethylene in Europe, for example. On the recycling side, there will also be a range based on transportation costs for collection and sorting and then distribution to a customer.

Carbon Footprints Matter, For Polymers And LNG

Nov 18, 2021 1:55:23 PM / by Graham Copley posted in ESG, Hydrogen, Recycling, Polymers, LNG, Polyethylene, CCS, Ethylene, decarbonization, HDPE, carbon abatement, ethane, naphtha, climate, carbon footprints, recycled polymers, virgin polymers, fuel, Freeport LNG

The IEA Energy Efficiency Analysis Is Bearish On Recycling

Nov 17, 2021 2:30:42 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastics, Energy, Net-Zero, IEA, climate, packagers

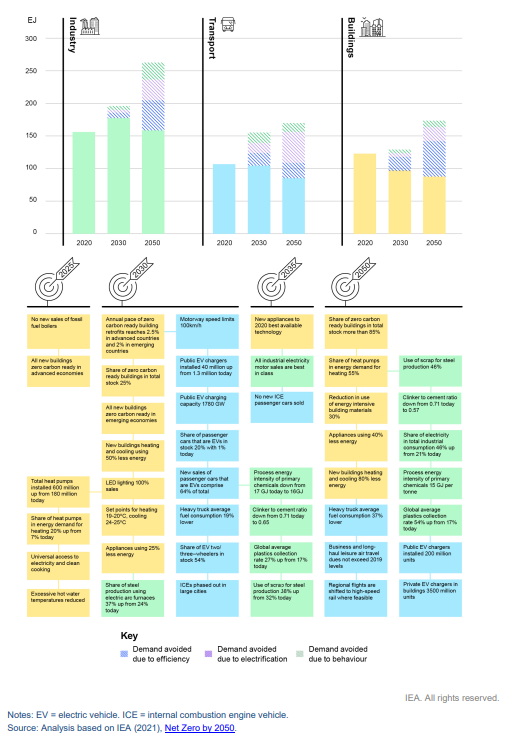

The IEA has published another report looking at energy intensity progress – noting that the rate of improvement in energy use is likely not fast enough to do its part in achieving net-zero needs. It is a comprehensive report (linked here) and we have chosen a couple of charts as you can see in today's daily report. The more interesting conclusion within the analysis may be that the IEA expects plastic collection for recycling to rise from 17% to only 27% by 2035. While this is a global average and will differ by country and likely by material, the overall rate looks low (but probably reasonable) and too low to allow packagers to meet recycle content goals, many of which are either 2025 or 2030 targets. We discuss some of the evolving packaging challenges in our ESG and Climate report today.

Recycle Availability Still Expected To Be A Headache For Packagers

Nov 16, 2021 1:02:05 PM / by Graham Copley posted in ESG, Recycling, Polymers, Sustainability, PET, Coca-Cola, polymer producers, renewable polymers, chemical recycling, low carbon, PepsiCo, Unilever, zero carbon, recycled polymers, FMCG, recycling goals

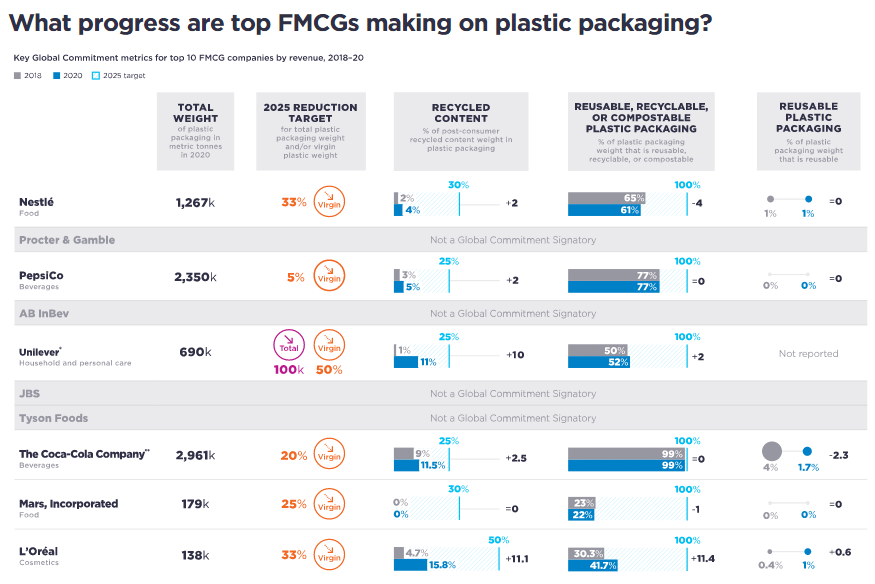

The chart below on recycling progress by the major FMCG companies is timely as it bumps into plenty of “national recycling day” headlines which include as many stories around recycling polymers into new applications as stories about like for like recycling. The more polymer that moves through collection and sorting and into roadbeds or composite particleboard replacement, etc., the less there is available for the FMCG companies to meet recycling goals. We see this as a major opportunity for the renewable polymer makers, but it is unlikely that there will be enough renewable-based polymers available to close the 2025 gap for most of the companies listed below. What is likely, in our view, is that the packagers will embrace chemical recycling as a way to increase their recycled content and will strike very specific deals with those able to show a chain of custody from collection through new polymer production.

Challenging Recycle Targets Suggest High Prices & Opportunities For Renewables

Oct 28, 2021 1:57:50 PM / by Graham Copley posted in ESG, Recycling, Sustainability, PET, polymer producers, renewable polymers, renewables, climate, recycled PET, virgin material, bio-polymers, waste, recycled material

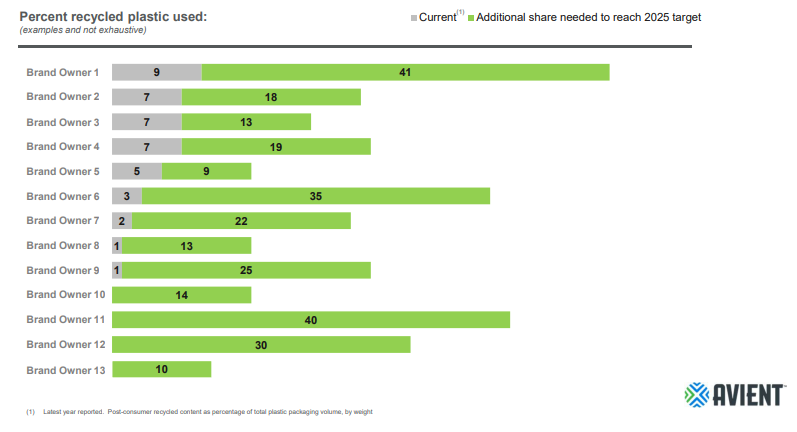

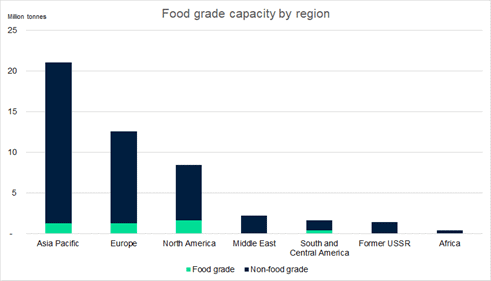

The Avient chart around where brand owners sit with recycled content versus 2025 goals is quite scary. There are not enough initiatives collectively to address the needs, as the demand extends beyond the 13 brand owners listed. In our ESG and climate report yesterday we talked about the challenges with recycled PET and the complicating factor around recycled material heading into different applications, and consequently not being available to bottlers. We also have the issue of PET bottle pre-form capacity being overweight in Asia versus PET bottle demand and waste – setting up an imbalance between where the waste is and where the recycled material is needed. The gaps in the Avient chart and the slow and challenging recycling progress lead to a couple of conclusions. The first is that recycled material is likely going to rise in value versus virgin material – simply because of competition and the PR, IR, Social cost of not meeting targets for many brand owners. The second conclusion is that the renewably sourced polymer producers have a huge potential opportunity to step in and fill the gap. The challenge will be the ability to have enough capacity up and running to meet demand in 2025.

Pretty Charts Hide Very Complex ESG Problems

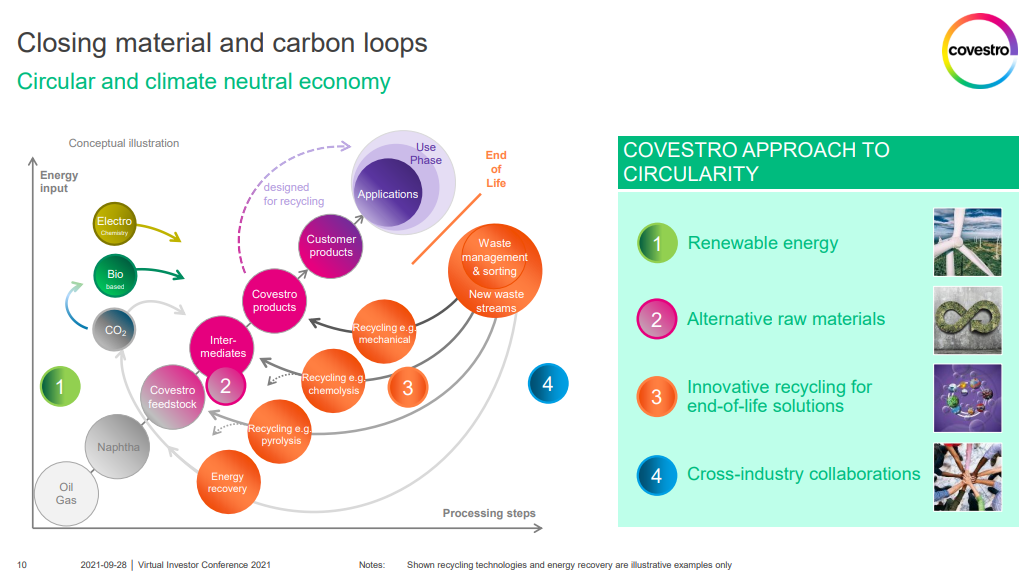

Sep 28, 2021 12:43:15 PM / by Graham Copley posted in ESG, Recycling, Climate Change, Sustainability, Carbon, Emissions, Mechanical Recycling, recycled polymer, Gevo, feedstock, chemical recycling, polymer, biodegradable plastics, Origin, polymer demand, Covestro

Companies are being encouraged/forced to produce climate plans by ever more focused shareholders many of whom only have a passing understanding of how some of the companies operate and how they might best set a course to lower emissions and otherwise be better stewards of the environment. The pretty graphic by Covestro below likely looks much better than the data and ambition behind it really are. This is not necessarily meant as a criticism of Covestro, but the company like many others is being challenged to explain a very complex, process, and engineering-heavy set of options to an audience not really qualified to understand them – pictures with circles are easier.

Food Grade Plastic Proving Difficult To Recycle - Pyrolysis Is The Answer

Aug 26, 2021 12:40:00 PM / by Graham Copley posted in ESG, Recycling, Polymers, Climate Change, Plastic Waste, Plastics, Pyrolysis, chemical recycling, reuse, food packagers, food-grade polymer

The exhibit below will come to many as a surprise, and it underlines one of the most significant challenges facing the recycling world. It is the food packagers who want the recycled content, but most food-grade polymer is not easily recycled (mechanically) once it has been in contact with food. Shrink-wrap for example is hard to collect and even harder to clean to a standard that is deemed safe and then hard to regrind because it is thin-film. This is where the polymer industry can really push the benefits of “advanced” chemical recycling as the process can take a mixed and not thoroughly cleaned stream of waste polymers with the recycling process itself (pyrolysis) destroying the contaminants and for the output that gets redirected back to ethylene units an additional shot at 1600-1700 Fahrenheit should remove any fears of contamination. You will not get the pound for pound recycle, but 35% is much better than the numbers suggested in the chart. Plus, in the process, you can destroy and reuse a great deal of plastic waste. See our ACC initiative write-up in yesterday’s ESG and Climate report.

100% Recycling: A Bold But Necessary Ambition For The ACC

Aug 25, 2021 1:33:16 PM / by Graham Copley posted in ESG, Recycling, Polymers, PVC, Plastic Waste, Plastics, chemical recycling, packaging polymers, ACC, plastics packaging, reuse, recycle, recover

The ACC goal of recovering 100% of packaging polymers is bold but likely necessary to show that its members are focused on a full solution, rather than some sort of halfway step. The goal is broken down as follows:

Friday Trio: Troubling US EV math, PET Tires, & New Exxon?

Aug 6, 2021 2:18:25 PM / by Graham Copley posted in ESG, Recycling, CO2, PET, ExxonMobil, Net-Zero, decarbonization, EV, carbon emissions, US Gasoline, electric vehicle goal, recycled PET, Continental

There are several things worthy of comment today. First, the math looks wrong in the Biden EV executive order, especially when combined with tighter fuel efficiency standards that are also on the table. The US consumes around 340 million gallons (approx. 8.1 million barrels) of gasoline a day and a reduction of 340,000 would only be a 1% reduction by 2030, even assuming growth in driving over the next 10 years we would expect the fuel standards and EV introduction to have a much more meaningful impact if successful. We will write more on this is our dedicated ESG and climate work.

Some Recycling Ambitions Expect Too Much Of The Consumer

Jul 23, 2021 12:43:02 PM / by Graham Copley posted in ESG, Recycling, Sustainability, Plastic Waste, Mechanical Recycling, chemical recycling, reusable plastics

The analysis behind the projections in Exhibit 6 in today's daily report, likely makes more assumptions than just the level of reusable plastics. To get the waste reduction projected, there will still need to be a step up in collection, sorting and recycling and it will all need to work to get the results desired. We are still concerned that these “high recycle” plans ask too much of an unwilling public, a slow to move average packager, and underfunded municipalities.

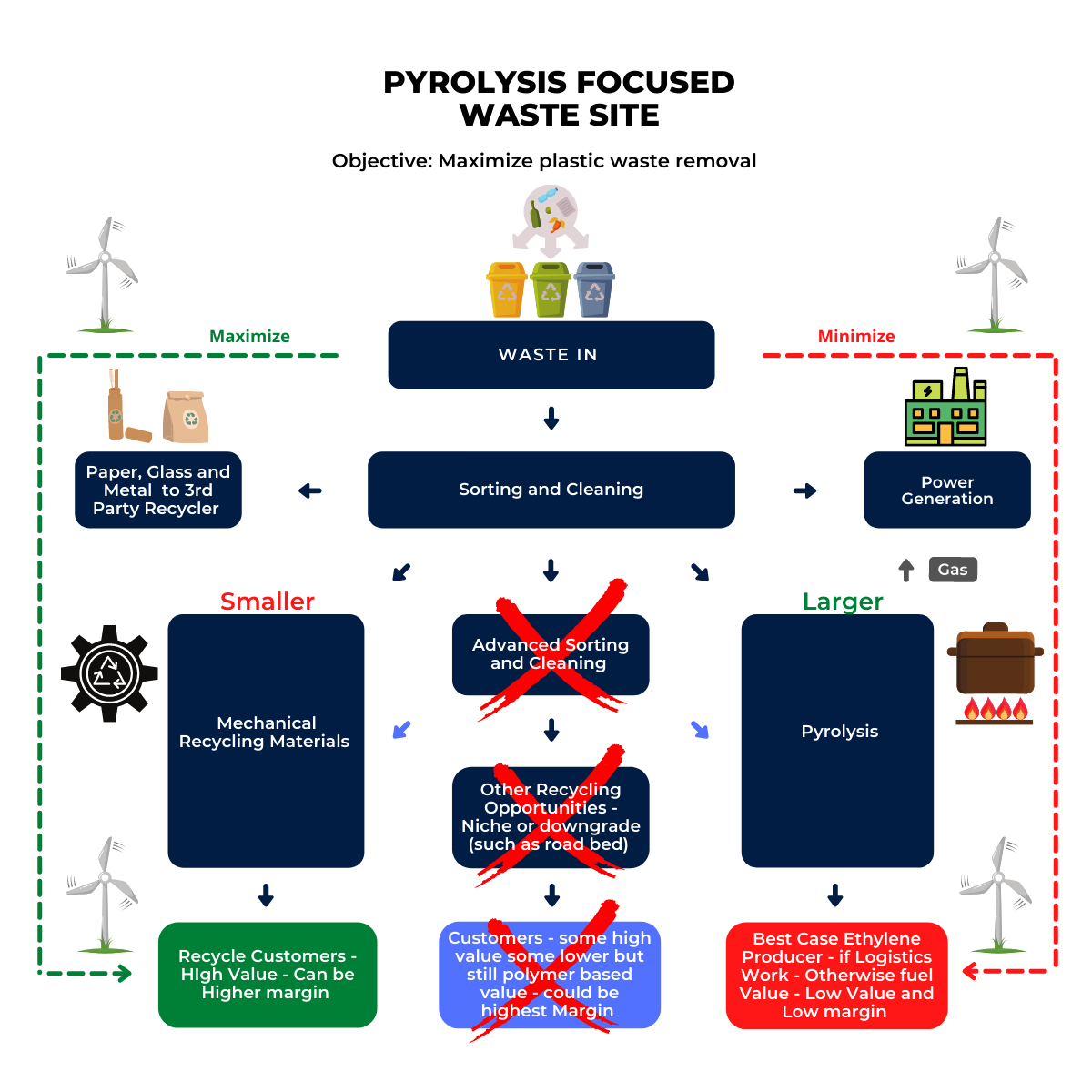

Chemical Recycling: An Easier Plastic Waste Than Recycling Story

Jul 20, 2021 2:23:38 PM / by Graham Copley posted in ESG, Recycling, Polymers, Plastic Waste, Pyrolysis, Mechanical Recycling, feedstock, chemical recycling, Agilyx, advanced recycling

The clear advantage of chemical recycling – as seen in the linked Agilyx headline – is that there are no issues with product cleanliness, etc., to get the material back into the cycle. As the polymers are essentially destroyed in the pyrolysis process and then reused as a feedstock in the traditional polymer production process, the rigors of sorting and cleaning for a mechanical recycling alternative are not needed. From a food contact perspective, chemical recycling is the easiest way to close the loop. What we are seeing in the headlines, however, is still “proof of concept” stuff and there remain plenty of challenges with logistics and/or proof of custody with the feedstocks that are flowing back to the ethylene unit, as well as how much recycling credit is appropriate, given that roughly half of the recycled feedstock does not end up as a polymer.