The clear advantage of chemical recycling – as seen in the linked Agilyx headline – is that there are no issues with product cleanliness, etc., to get the material back into the cycle. As the polymers are essentially destroyed in the pyrolysis process and then reused as a feedstock in the traditional polymer production process, the rigors of sorting and cleaning for a mechanical recycling alternative are not needed. From a food contact perspective, chemical recycling is the easiest way to close the loop. What we are seeing in the headlines, however, is still “proof of concept” stuff and there remain plenty of challenges with logistics and/or proof of custody with the feedstocks that are flowing back to the ethylene unit, as well as how much recycling credit is appropriate, given that roughly half of the recycled feedstock does not end up as a polymer.

Chemical Recycling: An Easier Plastic Waste Than Recycling Story

Jul 20, 2021 2:23:38 PM / by Graham Copley posted in ESG, Recycling, Polymers, Plastic Waste, Pyrolysis, Mechanical Recycling, feedstock, chemical recycling, Agilyx, advanced recycling

Solar: A Clear Example Of Potential Renewable Energy Inflation

Jun 17, 2021 1:32:30 PM / by Graham Copley posted in ESG, Hydrogen, Biofuels, Polymers, ESG Investing, Electric Vehicles, Raw Materials, LyondellBasell, Inflation, Gevo, solar, polysilicon, Wacker, copper, silver, Aemetis, renewable energy

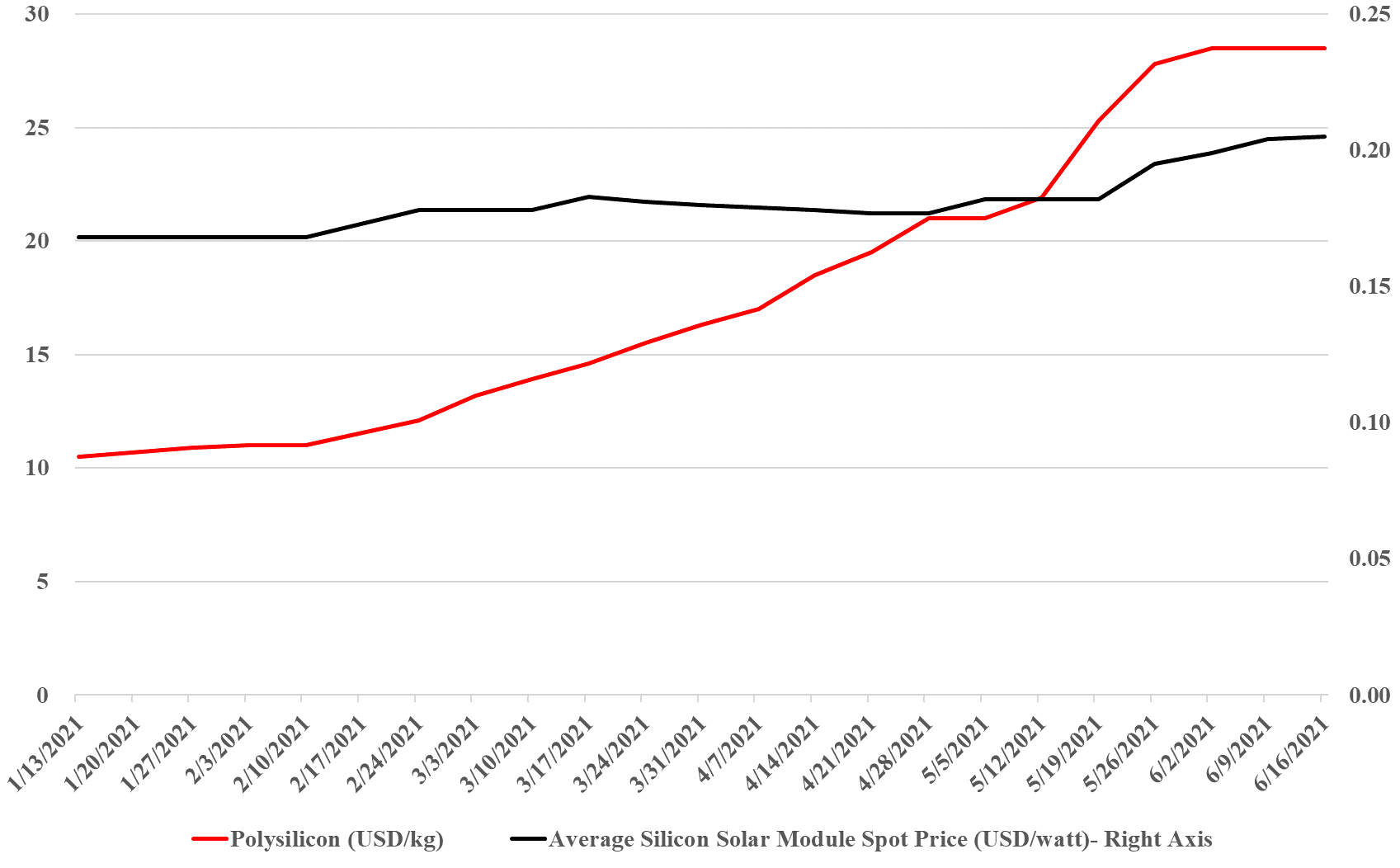

The exhibit below summarizes well one of the primary concerns that we have with some of the very ambitious goals for decarbonizing power grids, EV introduction, the further electrification of industry, and hydrogen. While the solar module price increase does not look that significant (yet), to put it in context, solar module prices have collapsed from over $1.80 per watt in 2010 to below $0.20 in 2020, and many of the expectations around cheap hydrogen require the cost to keep falling. The bigger concern is the polysilicon price, which is up 160% this year, good for the polysilicon producers like Wacker (see the headline here), but bad for the solar module producers, who are seeing major margin squeezes, especially given the rise in copper and silver as well this year. The raw material pressure should drive further increases in solar module pricing and while the higher margins for polysilicon will likely drive expansion investment, the metals are harder to call, given the ESG views on mining. We remain firmly of the view that raw material availability and price inflation, as well as module and wind turbine manufacturing capacity, will be the rate-determining constraint in terms of the growth in renewable power and this is why we question all of the near-term cheap power and cheap hydrogen goals that are being suggested by potential producers and government agencies.

More Recycling News. Hopefully More Recycling Action

May 27, 2021 1:48:57 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Polypropylene, Pyrolysis, Mechanical Recycling, LyondellBasell, Dow, unrecyclable polymer, sorting and cleaning, Nova, Closed Loop Partners, ethylene feed, PE

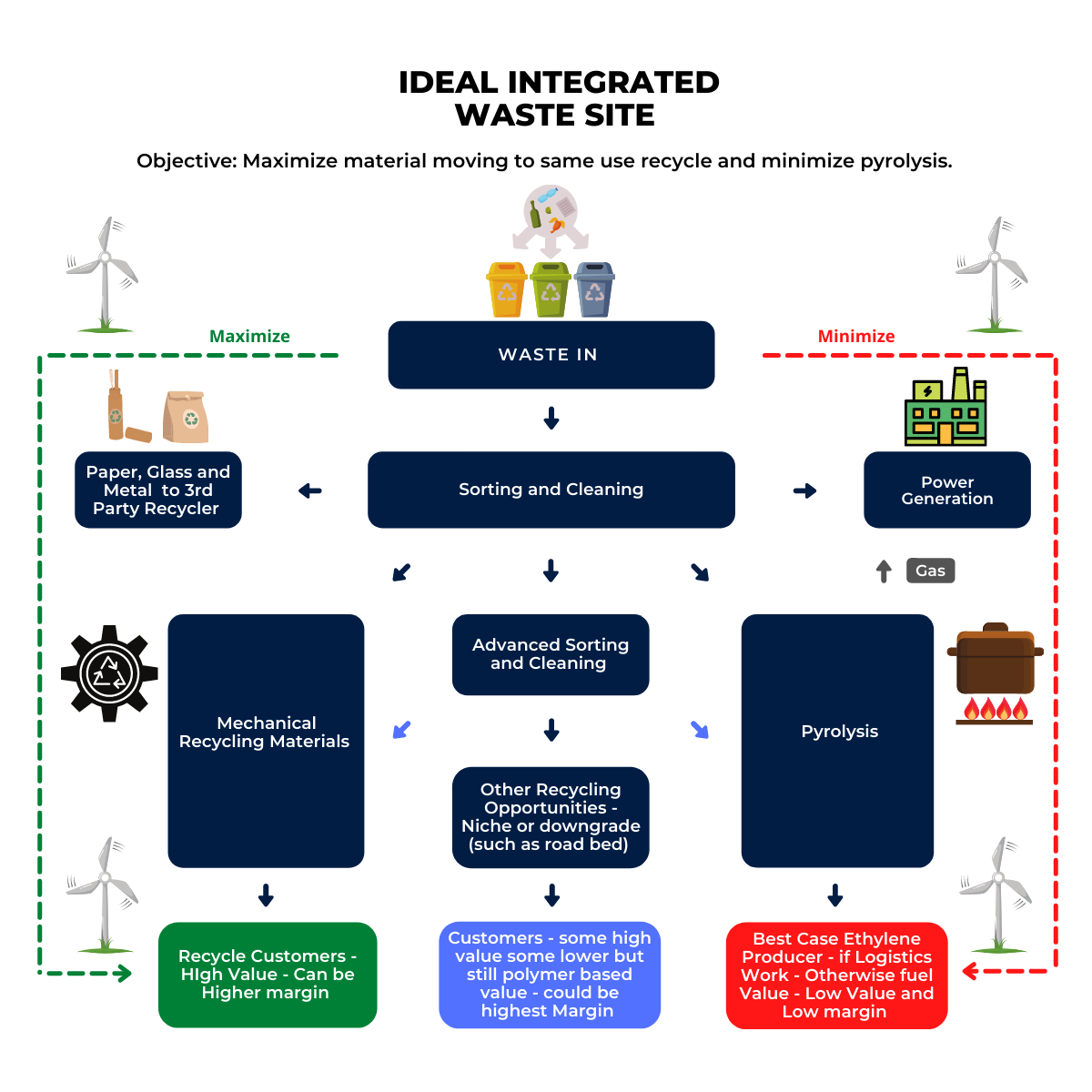

The Dow, LyondellBasell, Nova, Closed Loop Partners announcement yesterday is worth some thoughts. Closed Loop Partners is a PE company focused on funding recycling opportunities, but by its nature, it is relatively risk-averse as it has return goals to meet for its investors – to date its investments have been low-hanging fruit and niche in nature, but steps in the right direction nonetheless. The investment from the majors perhaps gives Closed Loop some wiggle room to look at projects that are less of a sure thing and maybe require a leap of faith on untested technologies or at least technologies untested at scale – primarily in sorting and identifying polymers and cleaning. We would still expect each project to be small, simply because access to the clean and easily sorted polyethylene and polypropylene in the US is limited by very poor standards of recycling and the vast proportion of unrecyclable polymer that ends up in a waste stream. If the group can find locations with significant supply, it might be wise to build pyrolysis at the same site to deal with everything that cannot be recycled. Our hope for this investment is that it is not simply an ESG PR opportunity for the polymer producers and that it does the following:

Packagers Are Looking At Renewable Sources As Recycle Availability Is Limited

May 20, 2021 2:17:33 PM / by Graham Copley posted in Recycling, Biofuels, Polymers, PET, packaging, Gevo, Supply Chain, Butanol, Coca-Cola, packaging materials, biogradable polymers, Renewable Sources, hydrocarbons

The coverage of the IEA study continues with lots of opinions, which is a good sign as it means that the work is being taken seriously.

Consistent Supply Of Recycled Plastics Will Require Consistent & High Enough Pricing

May 13, 2021 1:37:30 PM / by Graham Copley posted in Recycling, Polymers, Polyethylene, Plastics, Polypropylene, recycled polymer, polymer pricing, hydrocarbon prices, virgin resins, supply and demand, raw materials inflation, LyondellBasell, Suez, polymer buyers

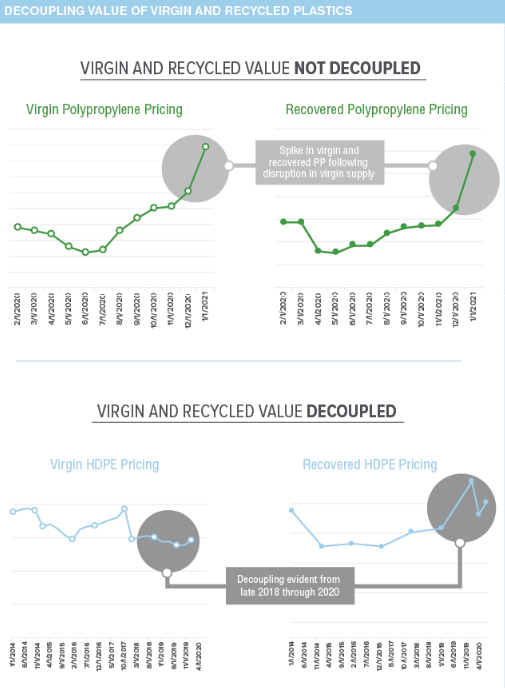

We talked a little about recycled polymer pricing in our ESG and Climate report yesterday. Recycled polymer pricing is rising relative to virgin polymer pricing (see chart below) and is likely to continue to rise unless hydrocarbon prices push virgin resins materially higher. Demand for recycled polymer is growing quickly and more quickly than supply, and we expect this to be reflected in an increased premium, barring more raw material inflation. Recycling is a fixed cost business – each step has a well-understood cost and companies are innovating to try and lower the cost of each step, but as so many different stakeholders are in the chain, it is a complex problem. One of the reasons why see the LyondellBasell/Suez venture works in The Netherlands is because Suez controls the waste in a region where recycling compliance at the household level is high. Despite this, it has taken a couple of years to get to the volumes needed to make the venture adequately profitable – mostly ensuring enough pure recycled polyethylene and polypropylene makes it to the facility. If polymer buyers are willing to cover the full cost of recycling in terms of the prices they are willing to pay, more material will become available – if LyondellBasell/Suez can demonstrate that they can make money when all the stars are aligned, it will likely encourage them to work with other municipalities in other parts of Europe (first) to see if they can replicate what they are doing now. In our view, all of the other advertised recycling programs are very small, very focused on niche applications, and don’t move the needle.

Pyrolysis Will Never Win If Consumers Are Willing To Pay For Recycled Plastics

Apr 30, 2021 1:46:22 PM / by Graham Copley posted in Recycling, Polymers, Plastic Waste, Plastics, Pyrolysis, Mechanical Recycling

Recycling is a fixed cost business – it does not vary with the price of oil or the price of natural gas – and the more willing potential customers are to pay on a fixed cost basis, to cover the collection, separation, cleaning, and re-pelletizing costs, the more recycled material will make it back into the cycle and not into landfill or pyrolysis. The pyrolysis technologies being discussed by the major polymer producers are a solution to the plastic WASTE problem, and they allow for a degree of recycling potentially, but they will never be able to bid waste polymer away from a mechanical recycling alternative if the buyer is willing to cover the costs. We have written extensively on these topics in our ESG and Climate reports and we would point readers back to Unwanted: Chemical Recycling – Necessary Now, Less So Later and the second section of True Blue: Not Green but Likely Good Enough.

Plastic Waste Challenges Revisited

Mar 11, 2021 11:20:12 AM / by Graham Copley posted in Recycling, Polymers, Plastic Waste

We are back on plastic waste today, following the IHS World Petrochemical Conference post that collaboration is key to evolving the circular plastics economy, reminding us what the largest challenge is regarding creating a circular plastics economy. Our work on trying to find a waste solution for a specific source material that we have discussed in prior reports has shown us firsthand how difficult it is to get the parties that should be interested in collaborating to talk to each other. While some see the waste problem as an urgent need, generally those that have the waste and are looking for a solution, others that are needed to complete the chain, have the issue far down their list of priorities. Making matters worse is that the margin in the collection, sorting, and then finding the most appropriate home for different streams of waste, is very small unless you are very efficient and/or unless you know that you are getting a disproportionate amount of material that can be upgraded (mechanically recycled) versus downgraded (chemically recycled).

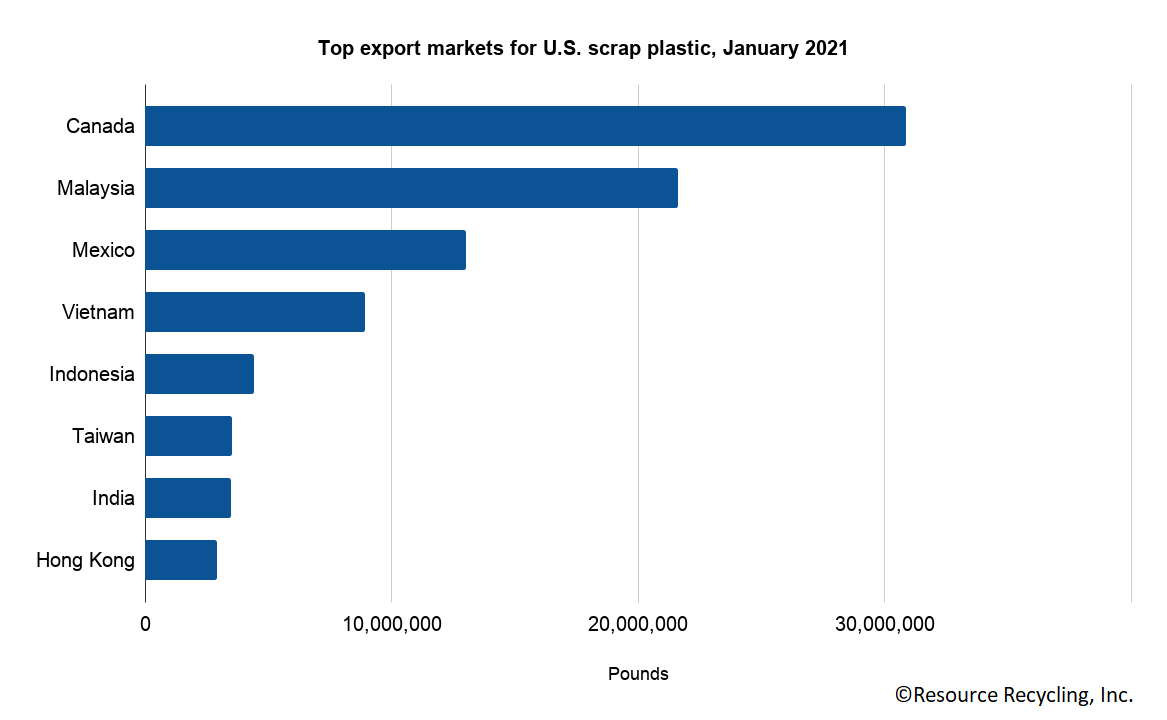

An added complication is that when China was taking waste, there was a payment for the mixed plastic and consequently, many who were involved in that trade are used to being paid for the waste – and have higher expectations of the margins to be shared than are likely available – in other words they want more for the plastic than it is worth locally, especially in a downgrading chemical recycling process.

Source: ResourceRecycling, US Census Bureau

In the chart above, it is likely that the prices being paid for the plastics that are being exported are very low and we have seen instances of local municipalities paying to have waste removes as it is less expensive than landfill – this is a mindset that is needed broadly to generate solutions for waste disposal and the optimal use of the various plastic waste streams. IHS is spot on with its call for greater collaboration, but that collaboration is not at a national level as the waste polymer is spread nationally and internationally and is a problem for local municipalities, counties and if they are coordinated, States, within the US. It is not one instance of collaboration and investment that is needed - it is thousands and while some solution investments may be common, many may not be. This one of the reasons why we believe that the chemical recycling ambitions of the chemical majors are wildly optimistic, given that outside of very large urban centers, they will need to work with hundreds of distinct local groups to get more material into the system. There is much more on plastic waste and recycling options in our March 3rd ESG and Climate Piece - Trash, or Treasure: Waste Plastic Challenges and Opportunities