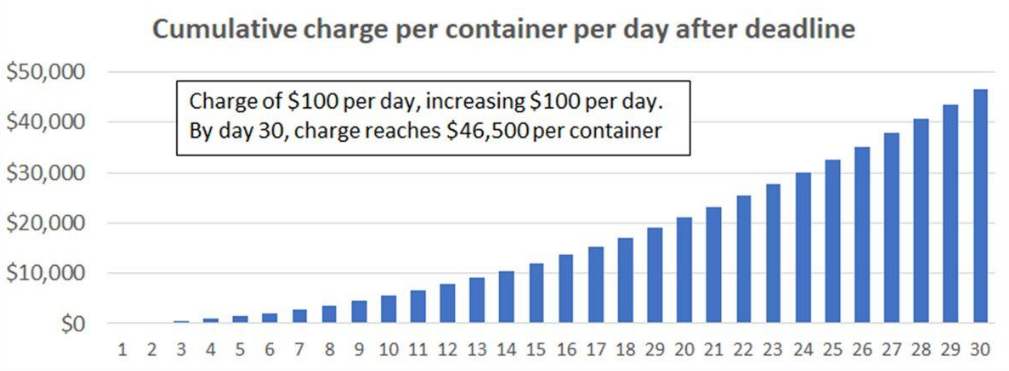

Shipping rates are falling steeply but we are not out of the logistic woods yet with the Ports of Los Angeles and Long Beach proposing very punitive charges for containers that are not collected quickly enough. The initiative is intended to decrease bottlenecks at the ports by clearing the docksides more quickly, but the reason why there are delays is often out of the shippers' and buyers’ hands as it is a lack of truck drivers and rail capacity that is at issue. The penalty rates proposed are steep and might discourage some shipments – especially of polymers and other low-value products. If it takes you an extra 20 days to offload a container from the port the cost of shipping polymers from Asia would double – very few importers would take that risk given the small margin opportunity that exists in the trade already. The penalties might encourage trucking companies to increase driver compensation to attract more drivers, but only if they can pass the potential penalty through to their customers. While this move proposed for containers may help drive down some of the port congestion times it is not a good sign for inflation as someone will have to pay – either pay the fines or pay up to improve resources to clear the containers more quickly.

Some Supply Signals Easing, But Some Proposed Fixes Are Inflationary

Oct 29, 2021 2:28:30 PM / by Cooley May posted in Chemicals, Polymers, Inflation, shipping, shipping costs, container freight rates, containers

Price Support From High Shipping Costs & Outages

Aug 11, 2021 2:17:47 PM / by Cooley May posted in Chemicals, Polyethylene, feedstock, PE, Asia ethylene, naphtha, ethylene costs, Asia polyethylene, US polymer prices, US propylene, ethylene feedstock, shipping, PE prices, US Polymers, shipping costs

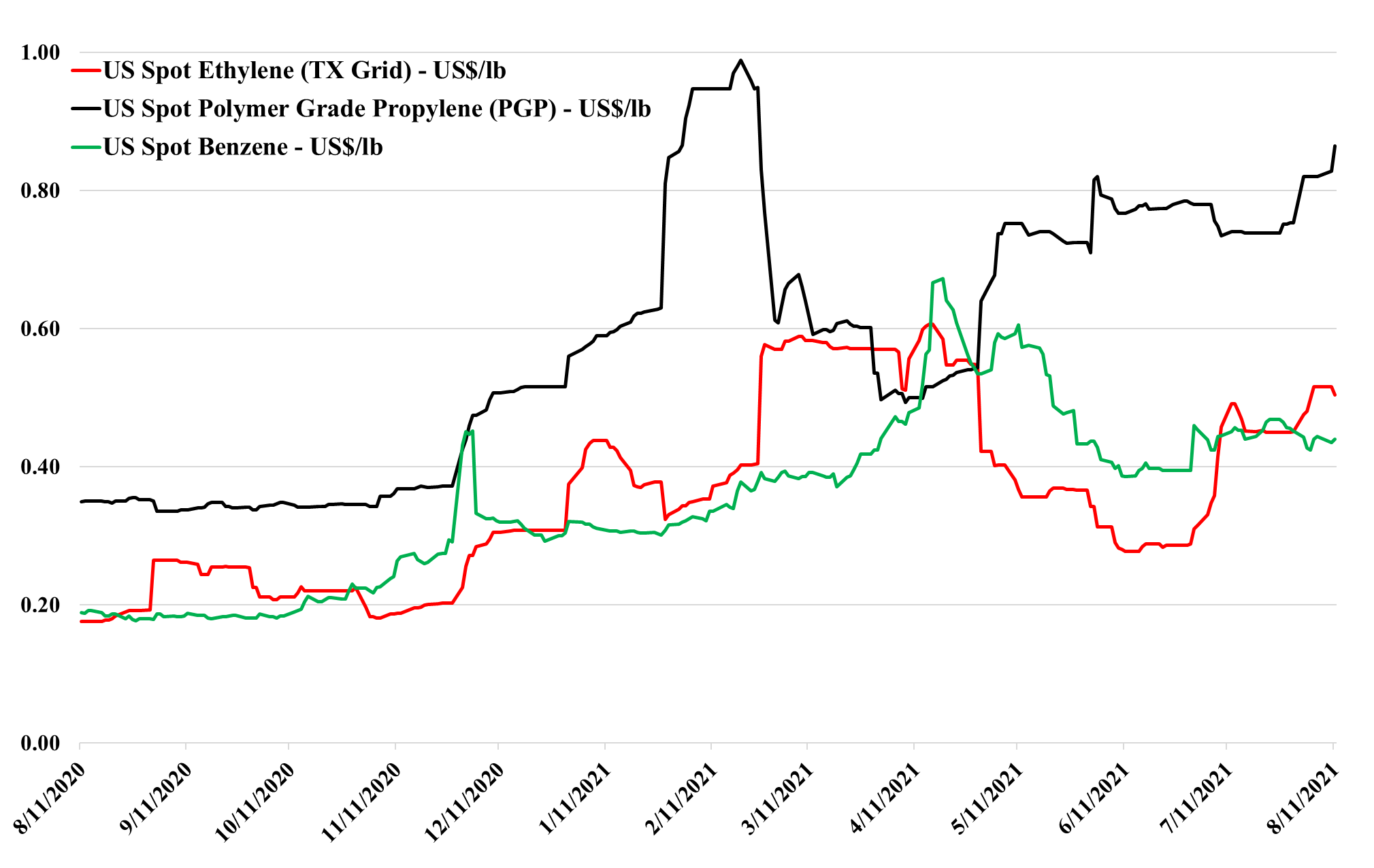

To put some perspective around the shipping container costs shown in Exhibit 1 of our daily report today, $20,000 per container equates to roughly 34 cents per pound of cargo assuming that the container is filled to maximum weight. If we also add in loading inefficiencies and assume 500 miles of road transport in the US or Europe, we can add another 5-10 cents per pound. Using ethylene costs in Asia at roughly 43 cents per pound as a basic benchmark (see our most recent weekly catalyst report), we thus estimate that it would cost around 90 cents per pound to get Asia polyethylene into the US. This does not include any working capital cost assumptions around ownership of the cargo from point of production to point of use. US spot PE prices are currently below 80 cents per pound for the more commodity grades of polyethylene, which is the market that could most easily be targeted by imports from Asia. When container rates were closer to $3000 per unit, the all-in import costs would have been roughly 30 cents per pound lower and the arbitrage would have been worth exploring. Of course, if the freight rate was only $3000 per container US polymer prices would likely be lower.