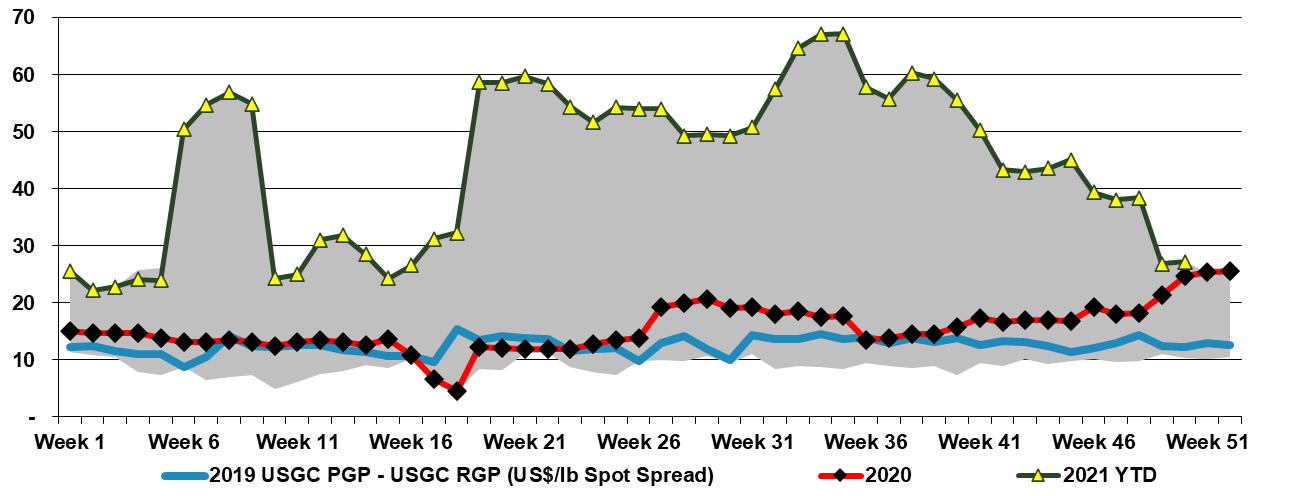

The CP Chem propylene splitter announcement linked suggests that CP Chem expects surplus refinery propylene to be around for the long-term, and likely has supply lined up from the parent companies. However, this is still a bit of a gamble unless both parents see a scenario where they would change catalysts on FCC units longer-term and run at higher severity for more propylene and more hydrogen. This project looked a lot better only a few weeks ago than it does today – based on the spread in the Exhibit below, but propylene demand continues to grow faster than ethylene demand in the US and with all incremental ethylene capacity based on ethane, propylene consumers either have to choose the path from refineries or invest in on purpose PDH. PDH is an energy-intensive process with a large carbon footprint, and splitting refinery propylene likely looks far less problematic from an emissions perspective, especially if there is surplus process heat on-site. In our ESG report today we talk about polymer recycling into new end markets, but polypropylene may see more direct substitution, especially if we see consumables related polypropylene recycled into durable polypropylene markets. This might dent demand growth for polypropylene going forward, but probably not meaningfully.

Refinery Propylene Remains A Cheap Source, If You Can Find It...

Dec 15, 2021 2:09:46 PM / by Cooley May posted in Hydrogen, Chemicals, Polymers, Propylene, Polypropylene, Emissions, CP Chemical, carbon footprint, ethane, PDH, ethylene capacity, polypropylene demand, refinery, Refinery Propylene, ethylene demand, surplus refinery propylene, polymer recycling, propylene splitter