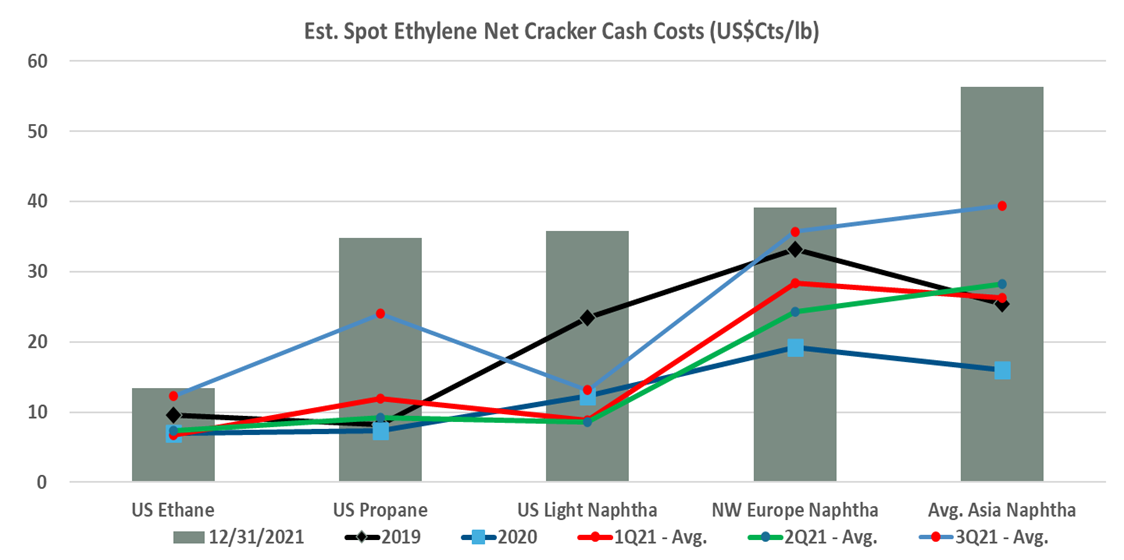

Given the higher prices of natural gas in the US, the shape of the current cost curve for ethylene in the exhibit below goes very much against traditional thinking and anyone looking at a historic crude oil to natural gas ratio as a proxy for the US competitive edge would be underestimating the advantage today. The major factor driving the change is the oversupply of ethylene co-products and their derivatives in Asia following a wave of new capacity in China and relatively lackluster growth locally during the Pandemic. As China and the region swung from net-short propylene and butadiene derivative markets to net-long, the price of derivatives declined and the price of the underlying monomers also fell – note that in our Daily Report today we show very positive margins for ethane based ethylene in the US and naphtha based margins in Europe, but negative margins in Asia and on top of that positive polyethylene margins in the US versus more break-even in Europe and negative in Asia. The exception in Asia is low-density polyethylene where there is extremely strong growth for solar panels, both for domestic markets and also for export.

The US Cost Advantage For Basic Chemicals Remains Significant

Jan 4, 2022 2:09:46 PM / by Cooley May posted in US Polymer, Asia prices, ethylene cost curve, Asia polyethylene, trade

Price Support From High Shipping Costs & Outages

Aug 11, 2021 2:17:47 PM / by Cooley May posted in Chemicals, Polyethylene, feedstock, PE, Asia ethylene, naphtha, ethylene costs, Asia polyethylene, US polymer prices, US propylene, ethylene feedstock, shipping, PE prices, US Polymers, shipping costs

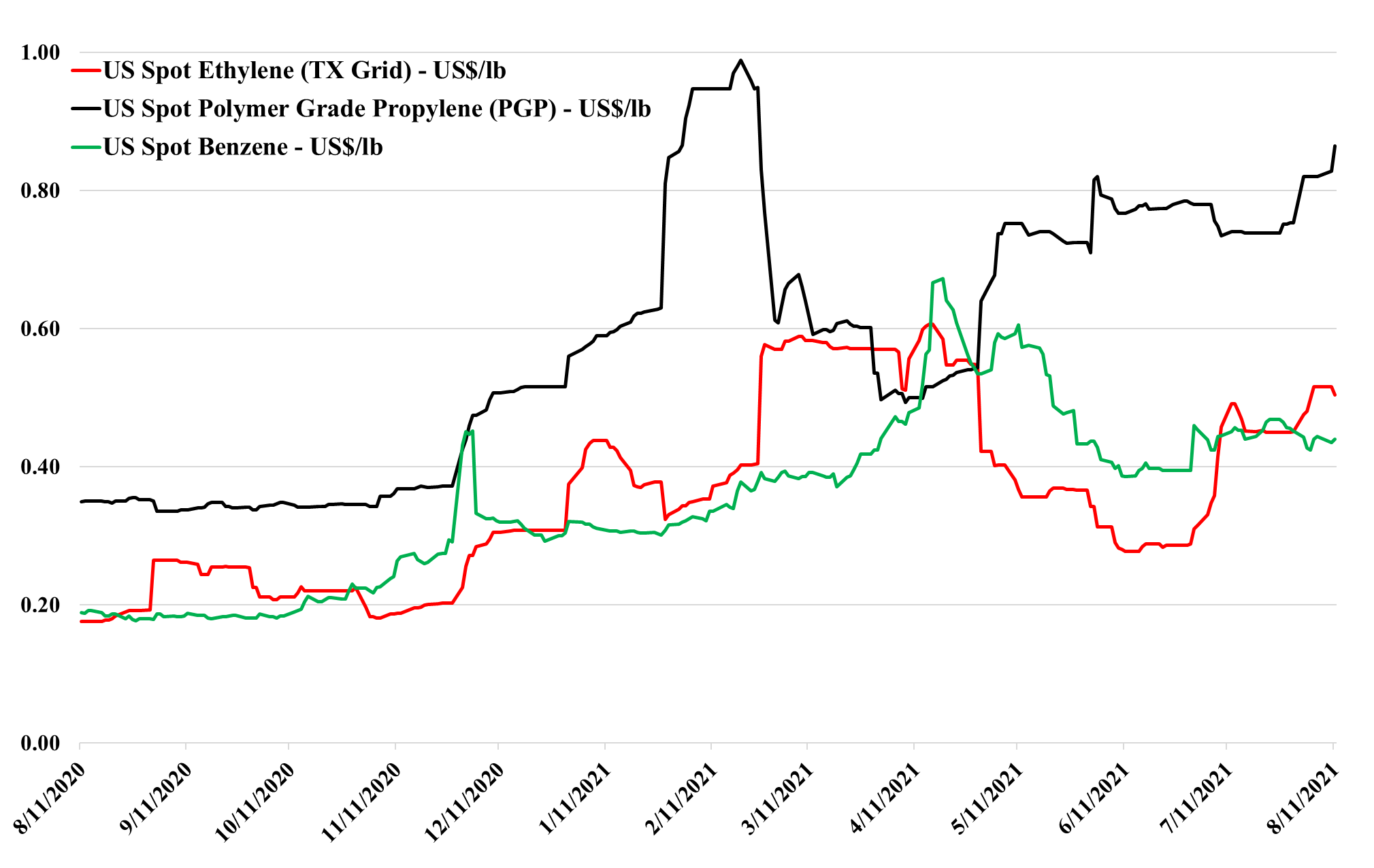

To put some perspective around the shipping container costs shown in Exhibit 1 of our daily report today, $20,000 per container equates to roughly 34 cents per pound of cargo assuming that the container is filled to maximum weight. If we also add in loading inefficiencies and assume 500 miles of road transport in the US or Europe, we can add another 5-10 cents per pound. Using ethylene costs in Asia at roughly 43 cents per pound as a basic benchmark (see our most recent weekly catalyst report), we thus estimate that it would cost around 90 cents per pound to get Asia polyethylene into the US. This does not include any working capital cost assumptions around ownership of the cargo from point of production to point of use. US spot PE prices are currently below 80 cents per pound for the more commodity grades of polyethylene, which is the market that could most easily be targeted by imports from Asia. When container rates were closer to $3000 per unit, the all-in import costs would have been roughly 30 cents per pound lower and the arbitrage would have been worth exploring. Of course, if the freight rate was only $3000 per container US polymer prices would likely be lower.