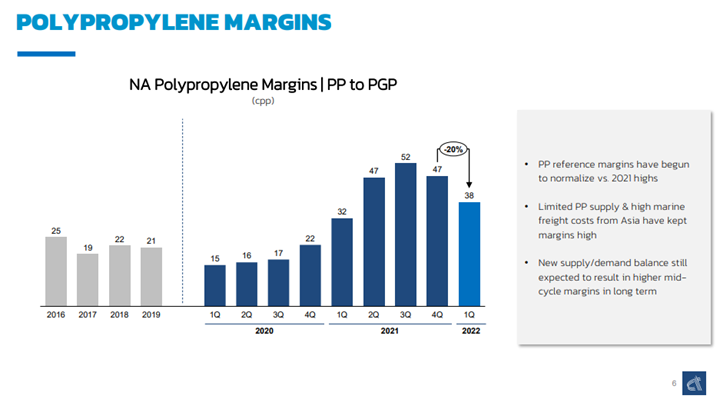

While Alpek shows a decline in the polypropylene to propylene spread in the exhibit below, it is important to note how high margins remain in the US. It is also important to note that the company points to high freight costs from Asia as one of the key drivers. China has significant polypropylene surpluses, and the price delta with the US is very high and, on paper, looks high enough to encourage imports into the US. But it is not that simple. The freight rates for containers from Asia are just one of many roadblocks, including wait time – on the water and the docks – and product quality. A US converter will likely not risk buying a few spot containers from China if focused on a product spec for a US customer. One way to get more material into the US would be for the end-user to buy the product – durable manufacturer or packager – and then ask its supplier to effectively toll-process. That way the product quality and logistic risk sit with the end consumer rather than the converter in the middle. The longer US domestic polypropylene prices remain inflated versus Asia, the more end-users may look at this option.

US Polypropylene & PVC: Both Benefiting From Logistic Challenges

Apr 27, 2022 12:32:52 PM / by Cooley May posted in Chemicals, Propylene, PVC, Polypropylene, freight, Logistics, US polypropylene, Alpek

Logistic Problems Are Far From Over: 2Q May Still Throw Some Curveballs

Apr 22, 2022 2:57:06 PM / by Cooley May posted in Chemicals, Supply Chain, Dow, Logistics, specialty chemicals, labor shortages, PPG, supply chain challenges

The linked China polyethylene headline highlights a possible risk for US producers, as we link much of what is happening in China to logistic challenges. China has high production costs in a high oil environment, which is driving some of the cutbacks, but a portion is likely driven by an inability to move product and a huge disincentive to build inventory at break-even or negative margins. If the current shipping challenges in China roll over more aggressively into the rest of the world and container and vessel availability fall again, the US may face more challenges exporting polymers. As warehouse space fills, especially on the Gulf Coast, we may see some need to cut back rates, even if all of the material in storage currently has an agreed home and an agreed price. The US can afford to build inventory, as production costs still remain attractive relative to international prices, but if the supply chain is full there could be nowhere to put more material. One of Union Pacific's issues highlighted last week was too much inventory in rail cars, snarling up the system.

Europe: Short Of Chemicals But Logistics Limit Help

Apr 1, 2022 3:34:45 PM / by Cooley May posted in Chemicals, Polymers, Ethylene, BASF, Logistics, energy costs, Europe

The BASF commentary about the impact of gas cuts in Europe should not be read as specific to BASF, but as we move out of the winter in Europe it is less likely that countries will directly restrict industry in favor of retail customers should gas supplies become limited. While many European countries will try to protect retail customers from hyperinflation in energy costs, their ability to do that for the industry might be more limited as they cannot find the additional gas, and subsidizing everything would be fiscally irresponsible. We expect to see more basic chemicals and derivatives moving from the US and the Middle East to Europe to displace uneconomic local production, but we understand that all shipping capacity is now constrained – liquids, gases, and containers – limiting the volumes that can move. The high end of the cost curve that Europe has occupied for decades in chemicals means that exports from Europe have been very limited and reducing exports is not a balancing act tool that Europe has to play with. We continue to see significant upward pressure on prices in Europe and the jump in inflation in the region, reported today, was dramatic but could accelerate as there are very few corrective levers that Europe can pull right now.

US Chemical Price Support Higher On Strong Demand

Feb 2, 2022 12:42:43 PM / by Cooley May posted in Chemicals, Polymers, Propylene, US Chemicals, Logistics, US propylene, propane prices, demand strength, propylene contract prices, propylene spot prices

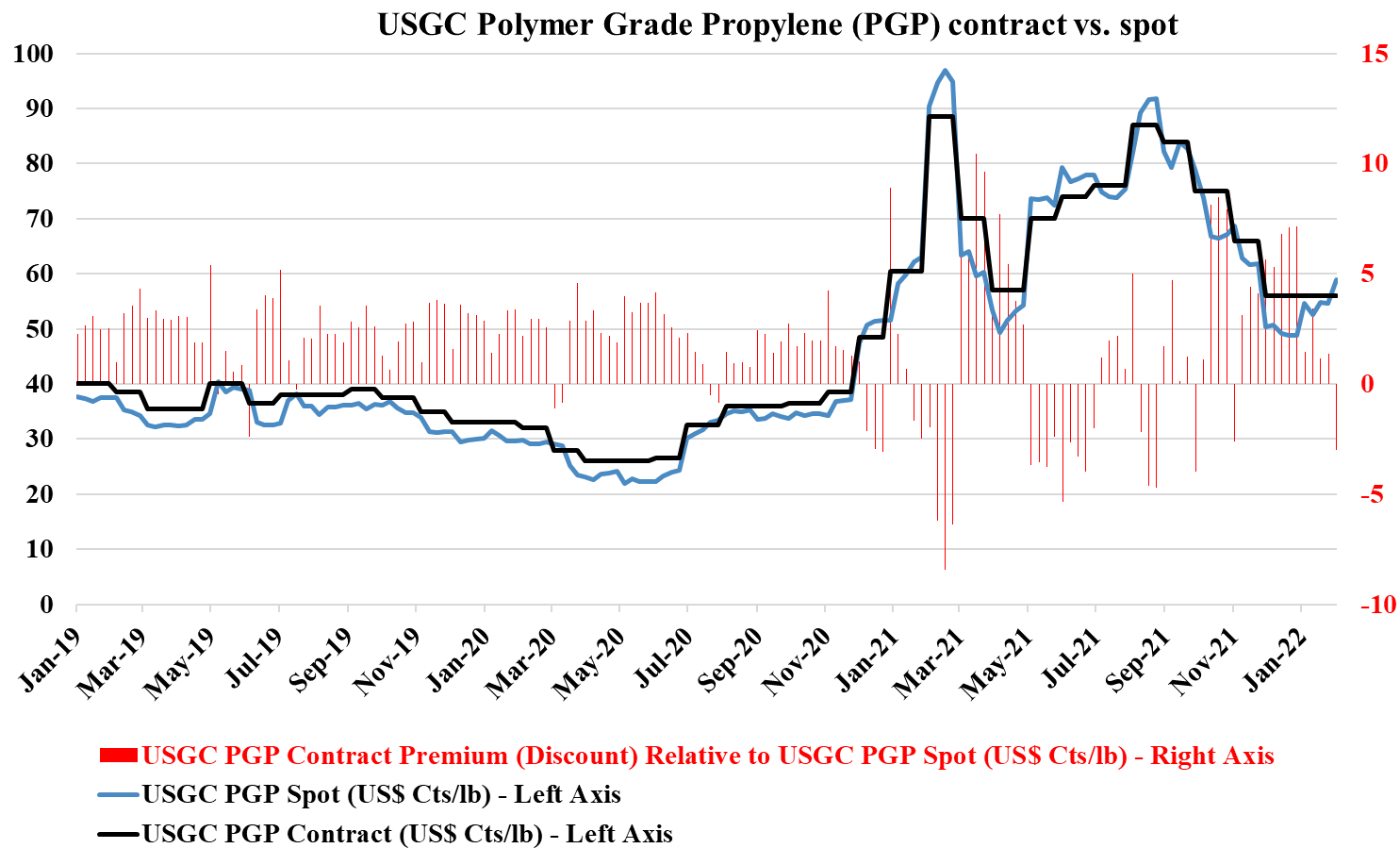

In a recent report, we discussed the relative demand strength in the US, as well as the high costs of importing chemicals and polymers into the US and suggested that higher energy and feedstock costs could arrest price declines in the US at levels that still drive significant profitability for US producers. With that in mind, it is interesting to note the upward move in propylene spot prices in reaction to higher propane prices and the resulting flat settlement in propylene contract prices.

US Polypropylene: Very Expensive But Clearly In Demand

Dec 7, 2021 2:55:45 PM / by Cooley May posted in Chemicals, Polypropylene, Chemical Industry, polymer, inventory, Logistics, polypropylene margins, US polypropylene, polypropylene demand

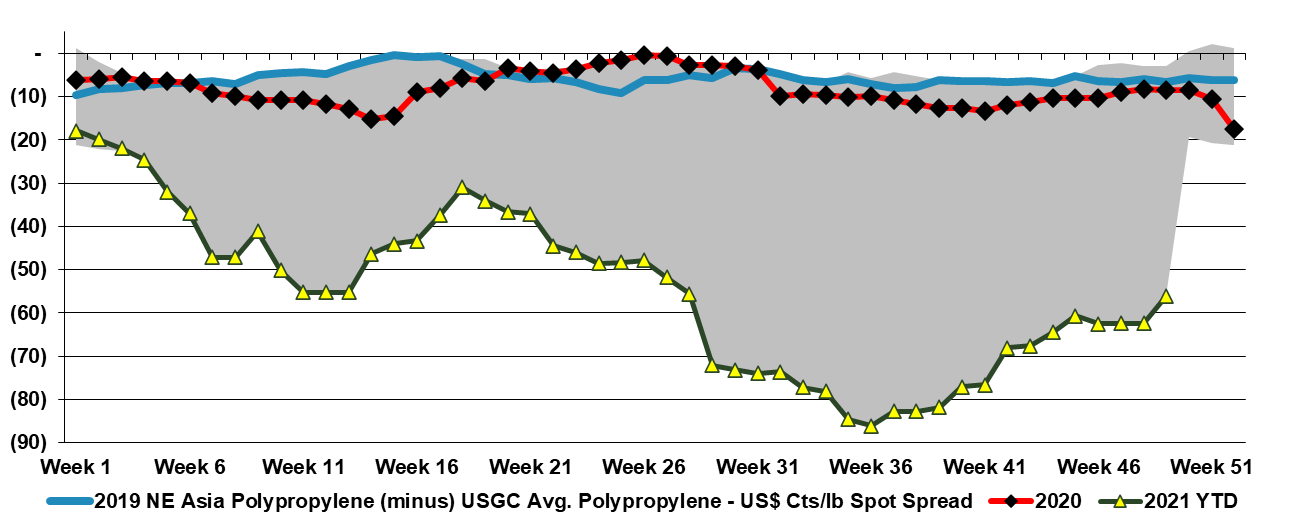

The polypropylene chart below, shows just how much of an impact the polymer has on the “average” in Exhibit 1 from today's daily report. Polypropylene is the only large volume polymer that can afford the freight rates to move surpluses from Asia to the US today and while some material is moving, volumes remain limited by the high cost of shipping and some of the additional logistic hurdles getting truck-based materials to US consumers that generally take the product by rail. The very high polypropylene margin in the US is a function not only of very strong demand but also demand that is likely growing faster than expected, giving buyers little negotiating room to get materially lower pricing. A year-end inventory correction from polymer buyers might send prices lower more quickly, but we have yet to see much evidence. We remain surprised by the apparent demand for polypropylene in the US given the lower automotive throughputs in 2021.

What's Contributing To Truck Driver Shortages & Why It Matters

Oct 5, 2021 8:31:12 AM / by Graham Copley posted in Chemicals, LNG, freight, Logistics, transportation, Shortage, truck drivers shortage, trucking

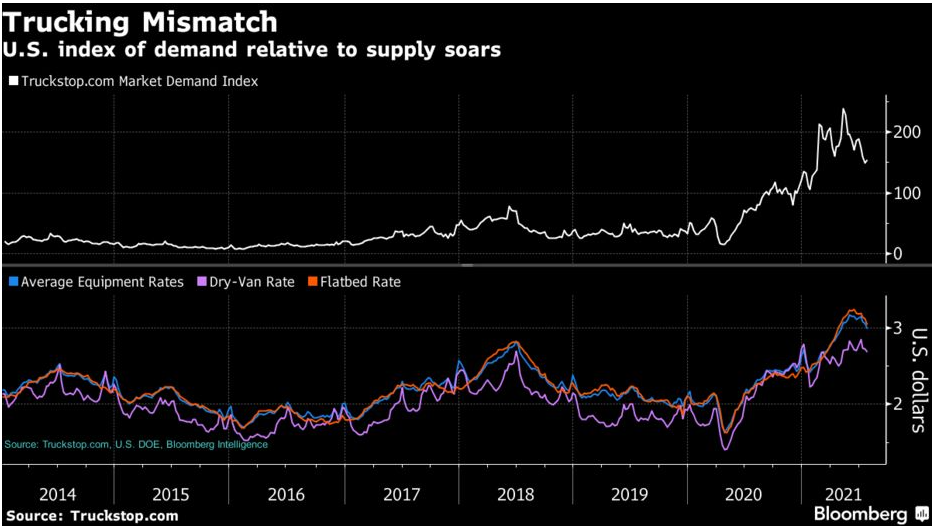

Our Sunday thematic and weekly recap report covers how the US is short of truck drivers (60,000) during a period when freight is struggling to move from congested ports – holiday buying will add more stress. This matters because we have record shipments of containers on the docks at US ports and record shipping backlogs waiting to unload as well as well documented shortages of durables in warehouses and at retailers.

The image below shows the mismatch in driver availability and trucking rates:

Logistic Issues Are Far From Over For Chemicals and Plastics

Jul 16, 2021 2:05:21 PM / by Cooley May posted in Chemicals, Plastics, Supply Chain, Logistics

We talk at length about the weather risks in the US following multiple extreme weather events during the last 12 months, but we forget that other regions are equally susceptible. Not only are there many chemical facilities on the riverways impacted by the floods in Germany but a significant volume of chemical trade takes place by barge on the rivers for both gases and liquids. We do not have an industry impact assessment for this tragedy in Germany, Belgium, and the Netherlands, but on-site flooding, especially any flooding that impacts electrics, can result in extended shutdowns for repairs, as we have seen in the past in the US.