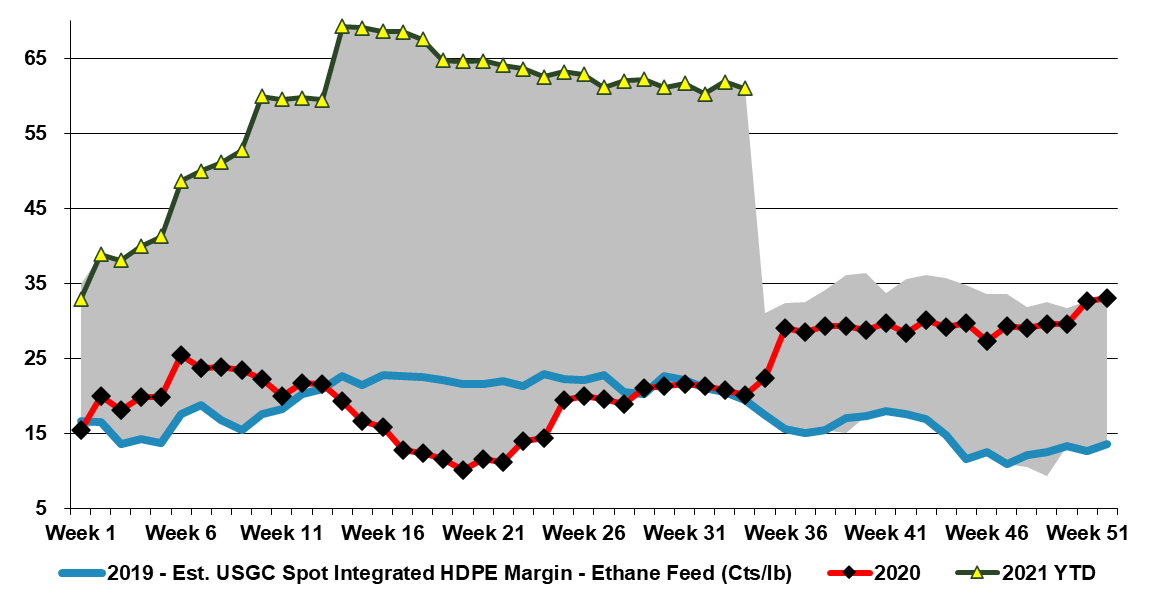

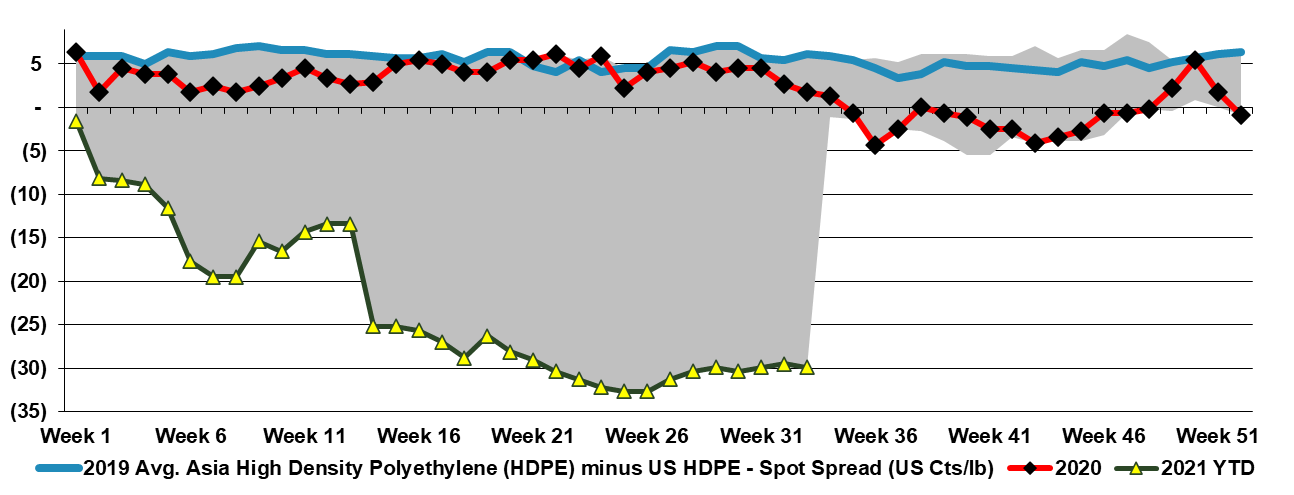

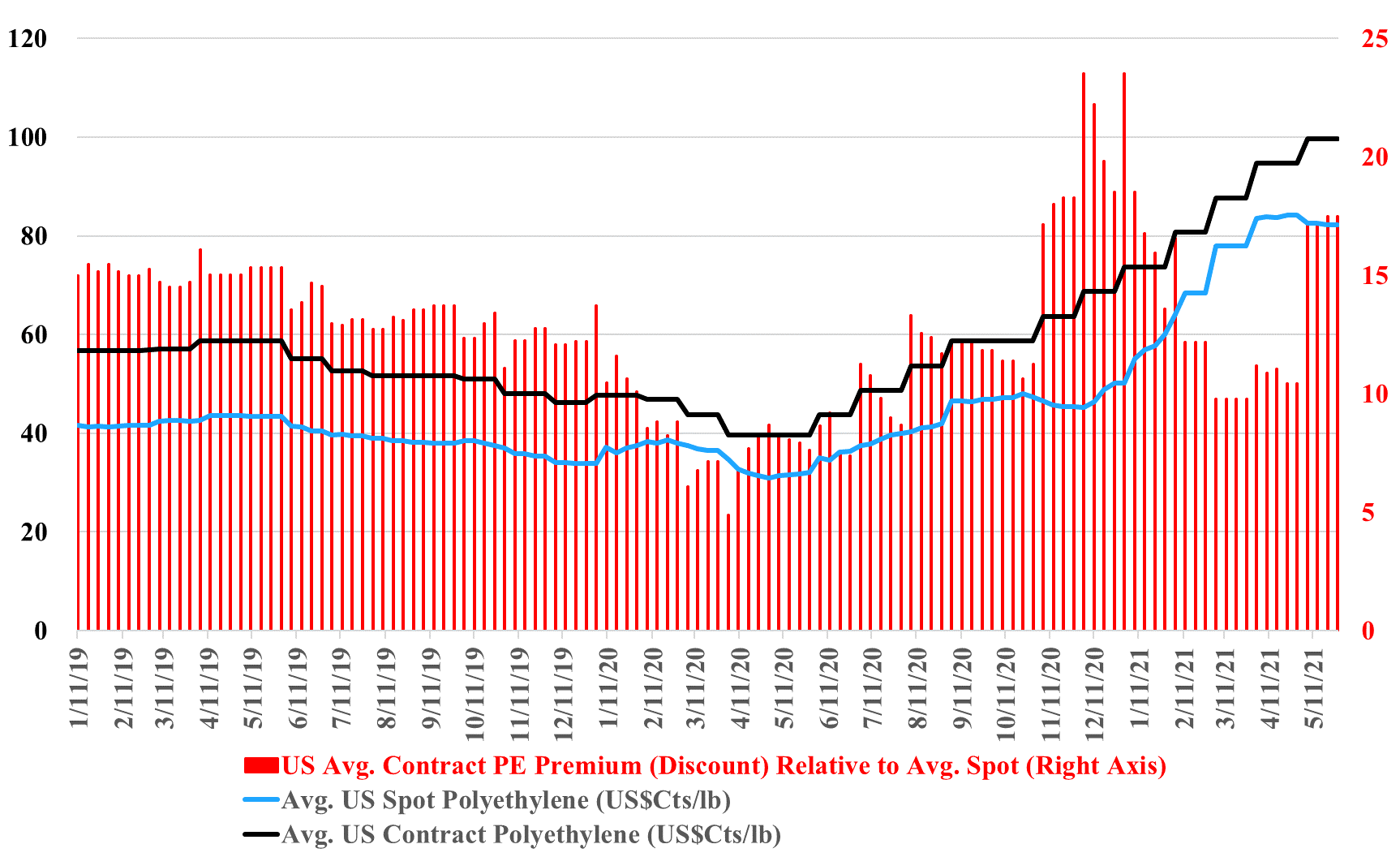

Is this the beginning of the end? The linked report that US traders are struggling to find export homes for incremental HDPE should not be a surprise given the significant price difference between the US domestic price and prices in other markets – Exhibit 1 in today's daily report. HDPE is the more fungible polyethylene, with both LLDPE and LDPE much more grade and application-specific. It is often the first polyethylene grade to spike in a shortage and fall when there is a surplus.

US Polymers: Are The First Cracks Appearing?

Aug 25, 2021 1:42:34 PM / by Cooley May posted in Chemicals, Polymers, Polyethylene, Ethylene, HDPE, derivatives, ethane feed, US Polymers, LLDPE, LDPE

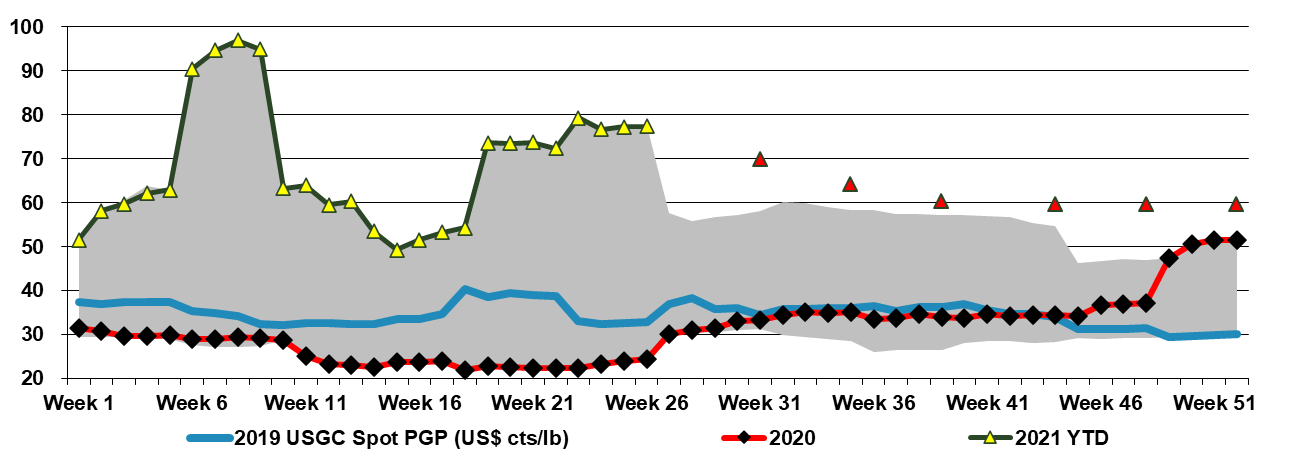

Polypropylene Should Be Traveling

Aug 17, 2021 6:16:09 PM / by Cooley May posted in Chemicals, Polyolefins, Polyethylene, Polypropylene, Export, arbitrage, polymer

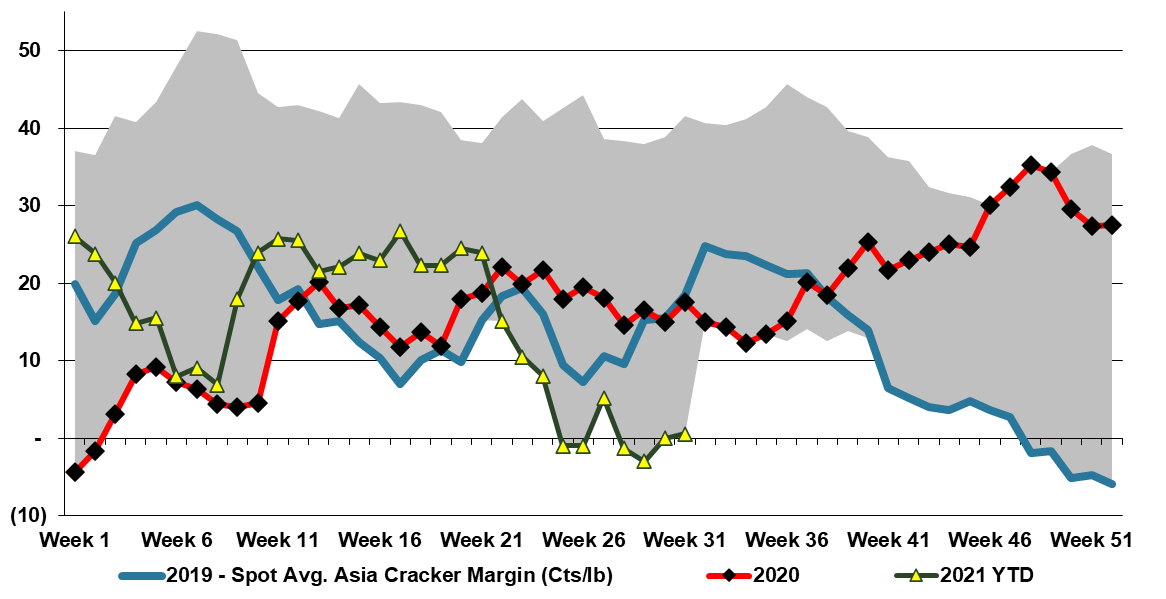

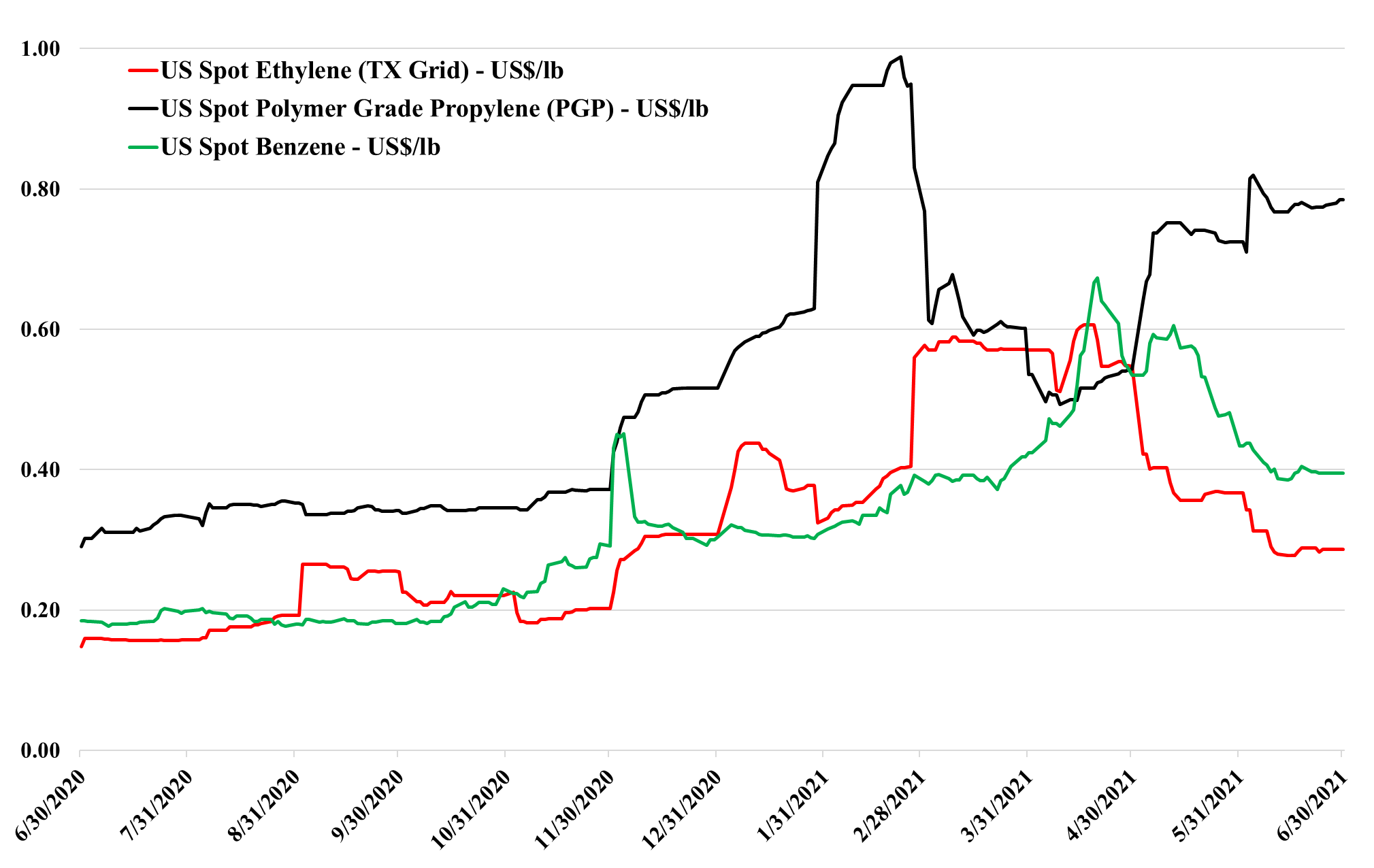

The chasm between US and Asia polyolefins prices remains wide, close to a 5-year high for polyethylene and setting new highs for polypropylene. The polyethylene arbitrage is not large enough to encourage US imports – first Exhibit below – largely because of the very high container rates from China.

Price Support From High Shipping Costs & Outages

Aug 11, 2021 2:17:47 PM / by Cooley May posted in Chemicals, Polyethylene, feedstock, PE, Asia ethylene, naphtha, ethylene costs, Asia polyethylene, US polymer prices, US propylene, ethylene feedstock, shipping, PE prices, US Polymers, shipping costs

To put some perspective around the shipping container costs shown in Exhibit 1 of our daily report today, $20,000 per container equates to roughly 34 cents per pound of cargo assuming that the container is filled to maximum weight. If we also add in loading inefficiencies and assume 500 miles of road transport in the US or Europe, we can add another 5-10 cents per pound. Using ethylene costs in Asia at roughly 43 cents per pound as a basic benchmark (see our most recent weekly catalyst report), we thus estimate that it would cost around 90 cents per pound to get Asia polyethylene into the US. This does not include any working capital cost assumptions around ownership of the cargo from point of production to point of use. US spot PE prices are currently below 80 cents per pound for the more commodity grades of polyethylene, which is the market that could most easily be targeted by imports from Asia. When container rates were closer to $3000 per unit, the all-in import costs would have been roughly 30 cents per pound lower and the arbitrage would have been worth exploring. Of course, if the freight rate was only $3000 per container US polymer prices would likely be lower.

The Last Conventional Ethylene Plant Built In The US?

Aug 4, 2021 12:58:57 PM / by Cooley May posted in Polyethylene, CP Chemical, Ethylene Price, supply and demand, oversupply, chemical recycling, Chevron, ethylene plant, E&P

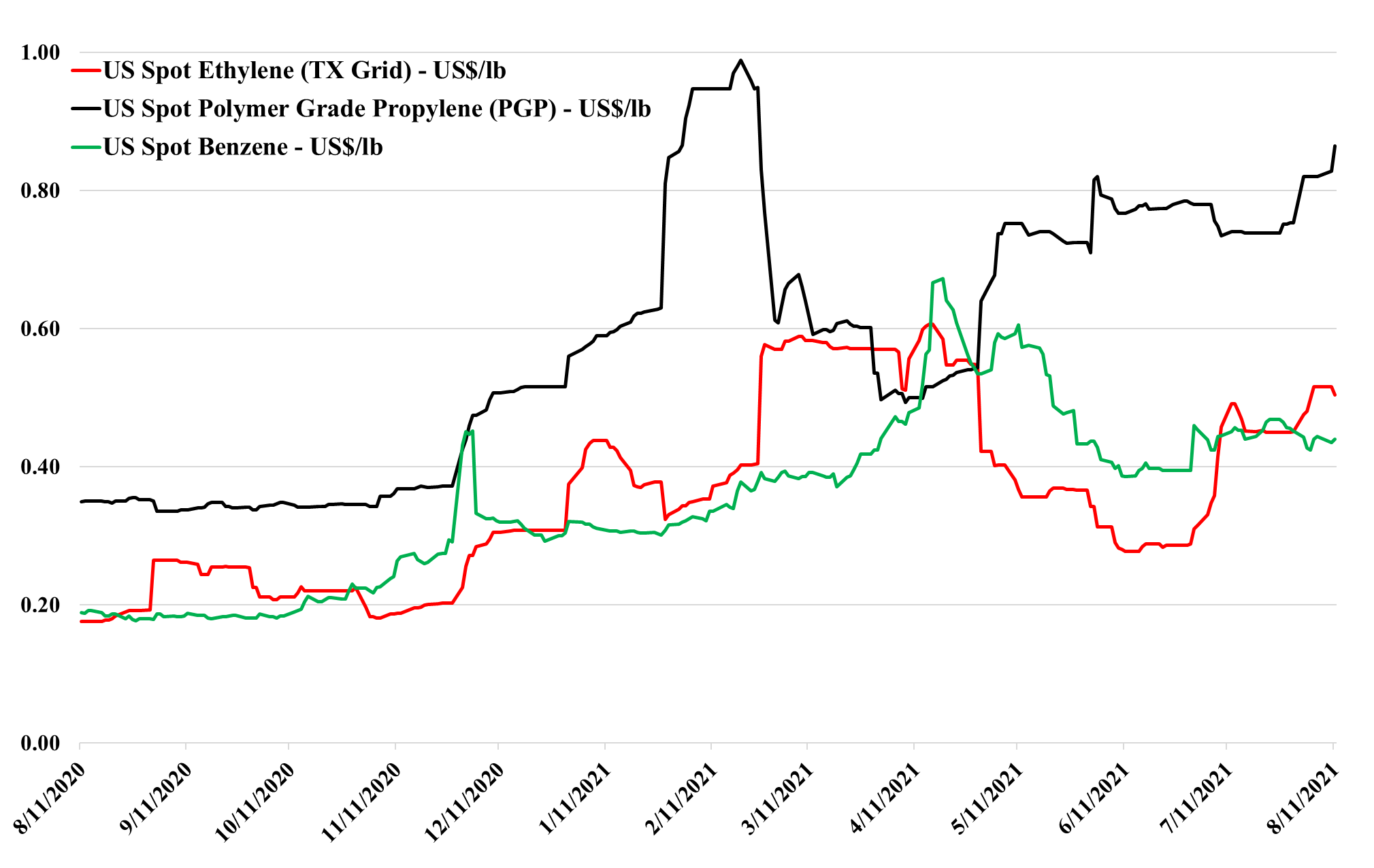

The ethylene price recovery in the US, discussed in today's daily report, is again a function of supply disruptions against a backdrop of robust demand. The net effect is to keep ethylene prices well above costs, at margins that justify investment and it is interesting to see the quick return of the CP Chemical project to the front burner. We could make a case that another ethylene facility in the US is likely a bridge too far at this point, despite the compelling current economics. The deep dependence on the export markets makes the US model very vulnerable to cyclical oversupply, and the current tight market is completely obscuring this risk and lulling producers into what we believe will be a misled sense of security. It is likely that the plants already built will prove to be good investments, not least because of the opportunity profits they are making in their early years of operations, but you would need to have a very bullish longer-term view of oil prices relative to natural gas to invest further, as even with an aggressive on-shoring manufacturing program in the US, the net export nature of the polyethylene businesses in the US is unlikely to change much. New capacity means more ethane demand, against a backdrop of lower E&P investment, and while Chevron has access to equity ethane from its US E&P operations, which may guarantee supply, it does not guarantee the price. Separately, while we believe that recycling targets in the US and the rest of the Wold will disappoint, they will still eat into virgin polymer demand. More chemical recycling will mean more “recycled” polyethylene available from heavy crackers – not ethane-based crackers.

ExxonMobil, SABIC JV Petrochemical Project Runs Ahead of Schedule

Jul 27, 2021 3:41:21 PM / by Cooley May posted in Chemicals, Polyethylene, Ethylene, Styrene, ExxonMobil, petrochemicals, petrochemical capacity, Dow, Sabic, Gulf Coast Growth Ventures, Aramco, Motiva, NPV, chemical plant, ethylene plant

ExxonMobil Chemicals has announced that its Corpus Christi JV project with SABIC is ahead of its original schedule – ExxonMobil is now targeting a start-up in 2H21, ahead of its previously targeted 1H22 expectation. It is unusual for projects in the US to be ready ahead of schedule these days, and start-up delays tend to be the norm. We also take a positive view of this development upon comparison to the Shell Pennsylvania project, which still has a vague 2022 start-up expectation though its construction began before ExxonMobil. One could argue that the remoteness of the location – well away from petrochemical infrastructure has been a constraint for Shell, but the Corpus Christi location is also a greenfield project for ExxonMobil/SABIC. This will be the largest ethylene plant built in the US, though it is likely that the recent 1.5 million ton units (Dow, ExxonMobil, CP Chem) are expandable to 2.0 million tons. Dow is already discussing such a move with a new polyethylene facility at Freeport. It will be interesting to see what impact this ExxonMobil/SABIC facility has on both the USGC ethane market and the polyethylene market – 1.3 million tons of polyethylene is a large increment and SABIC will have half of the capacity and will be a new market entrant with on-shore production. Aramco has ethylene, through Motiva’s purchase of Flint Hills, and SABIC owns half of the Cosmar styrene plant in Louisiana.

Sell It Or Store It: The Gamble For Ethylene Surpluses In 3Q

Jun 30, 2021 4:10:38 PM / by Cooley May posted in Chemicals, Polyethylene, Ethylene, US ethylene surplus, ethane feed

The higher ethane prices and the sharp increase in 2Q is likely offering some support for ethylene, but the more likely leveling factor of the last week or so has been the Nova outage and any lost production at Westlake, which will have a direct impact on export availability. Until ethylene spot prices in the US approach costs, which are around 10 cents per pound based on ethane feed, the more important driver of pricing will be whether or not there is a surplus and if there is what price is needed to generate export demand. The US ethylene surplus is equivalent to a couple of large plants and consequently, the market can swing from short to long depending on who is operating and is very vulnerable to weather-related closures, although these often take down ethylene derivative plants as well, creating shortages of the derivatives. Polyethylene can afford to pay more than y twice the current price of ethylene, while the ethylene export market needs a further step down from here. Consequently, the range of potential volatility in 3Q is very high – we underestimated the weather impact last year, as did everyone else and it would be a tough call today for a producer with a surplus as to whether to push it into the export market or hold on to it. See more in today's Daily Report.

US Ethylene & Propylene: Very Different Markets!

Jun 23, 2021 3:22:37 PM / by Cooley May posted in Chemicals, Propylene, Polyethylene, Ethylene, Monomer, polymer pricing, Baystar, US ethylene pricing, propane pricing, Ethylene Surplus

The Baystar polyethylene start-up date is consistent with the guidance that the company has been providing for a while, but it still leaves the venture with an ethylene surplus until that time and while the ethylene has been placed, according to the company, the ethylene that it has displaced will likely keep some downward pressure on US ethylene pricing until the polymer plant starts up (all things being equal). Even when the polymer plant starts, the US is expected to have a net ethylene surplus and we would expect exports to continue and prices to reflect levels to make the exports possible.

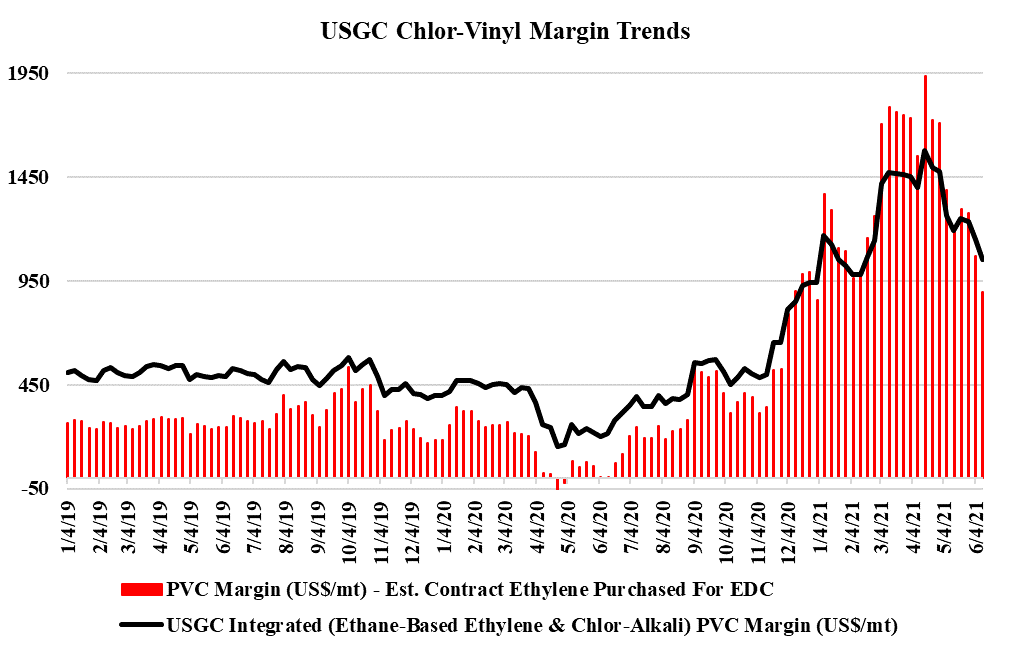

PVC Off Its Peak, But It's Long Term Outlook Remains Compelling

Jun 16, 2021 2:04:55 PM / by Cooley May posted in Chemicals, PVC, Polyethylene, Oil, PVC Margins, US Ethane

PVC margins are off their highs, as pricing is falling through June. The building product markets remain robust in our view, albeit off their highs, and some of the strength in PVC in April and May was a consequence of production shortages caused by the winter freeze in February. While PVC may be falling faster than polyethylene today, we see support for US PVC at higher prices and margins than for polyethylene in a weaker market unless oil climbs further relative to US ethane. See more on our daily report.

Propylene Too Expensive, Ethylene Cheap Enough

Jun 15, 2021 2:18:27 PM / by Cooley May posted in Chemicals, Propylene, Polyethylene, Polypropylene, Ethylene, Auto Industry, polymer pricing, consumer spending

The weakness in polymer pricing in Asia and the drag that auto sales had on US consumer spending in May (spending was up ex-autos) should begin to undermine the very strong polypropylene market in the US, and the fall may happen at a reasonable clip. Polypropylene is more fungible than polyethylene, in that much more of the customization of polypropylene comes post-production rather than during production. There are several unique polyethylene technologies, especially for linear-low where the process drives the properties and adds value. For polypropylene, while there is some of this, most product is compounded and consequently, there is more fungibility before compounding and less risk from experimenting with suppliers. If freight rates were not so high as discussed in today's daily, we believe that we would have seen a notable amount of polypropylene moving from Asia to the US by now.

More Indicators Point To US Polyethylene Contract Prices Near A 2021 Peak

Jun 3, 2021 11:48:26 AM / by Cooley May posted in Chemicals, Polyethylene, Ethylene, US Prices, polyethylene producers, Polymer plants, Polyethylene prices

While we continue to see valiant efforts from the polyethylene producers to increase prices further in June, this is what we used to refer to as a “cow in front of a train” strategy. In that throwing a cow in front of a train was not going to stop it, but it might slow it down a bit! Barring weather, it is inevitable that US polyethylene prices shown in the chart below will start to give back some of their premium pricing over the coming months. One factor among several others pointed out on today's Daily Report is that Ethylene is much weaker and the international markets are materially out of line, and if freight rates have peaked, the arbitrage will undermine prices in the US. Producers will do their best to hang on to the high margins for as long as they can, and a few more cows may be sacrificed, but the weather is their only hope.