We have covered some of our Huntsman logic in today's daily report, but we would like to point out another concern that we find with Starboard’s proposal – the focus on operations and the nomination of Jim Gallogly as a potential board member. While we have nothing but great respect for Mr. Gallogly, and the work he did at LyondellBasell, we are concerned that Huntsman’s business model would not be best served with a “larger than life” board member with a very strong commodity background. We have seen several significant mistakes made in the past by commodity-minded companies and leadership, applying somewhat linear thinking to acquired businesses and we believe this could be a risk here. When Dow acquired Rohm and Haas one of the few mistakes that were made was looking at the acrylic acid business like a commodity and trying to drive more production through the units. The effect was to oversupply the markets and depress pricing and margins and it took a couple of years for the right management team to get the business back on track. Huntsman likely does not need more polyurethane and epoxy production if doing so creates a race to the bottom with competitors and destroys margins. The intermediate and specialty chemical business is as much about matching supply to demand as it is about plant throughput and efficiency. Every company can improve its operations and improve efficiency and costs but for some businesses, more material is not necessarily better. We believe that Huntsman’s stock would react negatively if the strategy changed to one of pushing as much volume as possible.

Commodity Leadership Not Best For A Specialty Strategy

Jan 13, 2022 2:57:31 PM / by Cooley May posted in Chemicals, Commodities, Polyurethane, LyondellBasell, Dow, specialty chemicals, Huntsman, strategy

Inflation Is Everywhere And Detracts From Strong Chemical Growth

Jan 5, 2022 2:34:49 PM / by Cooley May posted in Chemicals, Inflation, specialty chemicals, intermediate chemicals

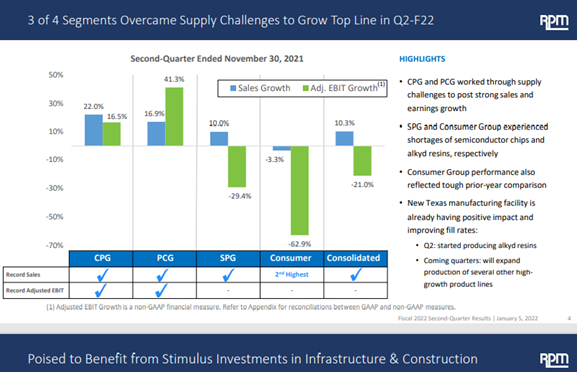

Following on again with our inflation theme, which features heavily in today's Daily Report, note that RPM’s release is riddled with references to inflation impacting results negatively as raw material and logistic costs increased. The commodity chemical and polymer producers have much more pricing flexibility than the specialty makers like RPM, and they can generally pass through higher costs quite quickly. For the specialty companies, there is generally a lag, as is clearly shown in RPM’s results, but they generally catch up with pricing as long as demand is robust, which it appears to be. The benefit for the specialty companies is that they can often hold on to price increases or at least some of the increase longer than a commodity producer can as raw materials and fundamentals ease. We expect the intermediate and specialty chemical producers in the US and Europe to have strong demand growth in 2022, as the reshoring momentum should continue and offset any risk of weaker consumer spending on durables as the year progresses. We have been more focused on companies that are selling materials into construction and renewable energy and EV markets, but RPM has enough exposure that it should also be a beneficiary as long as prices can keep pace with costs.

Many Adjustments Ahead For LyondellBasell

Dec 14, 2021 1:27:36 PM / by Cooley May posted in Chemicals, Recycling, Polymers, Propylene, Polyethylene, Polypropylene, LyondellBasell, Chemical Industry, energy transition, US Exports, specialty chemicals, Polyethylene Capacity, US polyethylene, US polypropylene, commodity chemicals, refinery, commodity polymer

Following on from the LyondellBasell commentary in today's daily report, we would make one further, but very important point. With its refinery (granted the company is exploring opportunities to exit) and its huge commodity polyethylene, polypropylene, and propylene oxide business, any attempt to pursue a “specialty” strategy that encompasses the whole portfolio will be seen (crudely) as trying to put some lipstick on a pig! This rarely works in the chemical sector and the real transformation stories involve wholesale portfolio shifts, many of which have taken notable periods of time to develop. We still believe that the right path for LyondellBasell is to spin off the good piece – recycling, licensing, and compounding, or even better, find someone they can sell the business to through a Reverse Morris Trust. This strategy would likely allow the company to pay down (or shift) a significant amount of debt. The commodity business can then focus on the best strategy for a commodity polymer business in the face of energy transition, which might involve taking the business private or merging with another.

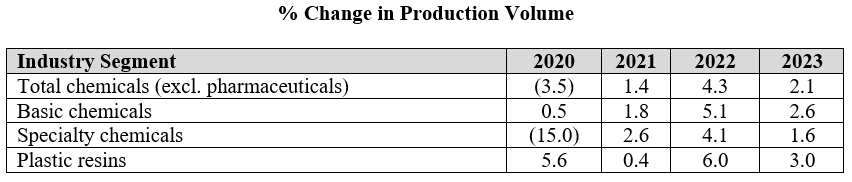

The ACC Forecasts Look Too Conservative To Us

Dec 9, 2021 2:15:01 PM / by Cooley May posted in Chemicals, Polymers, PVC, Polyethylene, Plastics, Polypropylene, Ethylene, Auto Industry, Shell, ExxonMobil, petrochemicals, Sabic, natural gas, natural gas prices, Baystar, Basic Chemicals, manufacturing, polymer production, specialty chemicals, ACC, Polyethylene Capacity, US manufacturing, plastics resin

The ACC forecasts below leave us a little confused as the implication for specialty chemicals is that production declines in the US by an average of 2.0% per annum from 2019 to 2023. Given the demand that we are seeing for US manufacturing, as covered in our most recent Sunday Report, we would expect demand for all inputs to rise and it is unlikely that the gap would be filled by a swing in net imports. The lower demand from the Auto industry in 2020 and 2021 and broader manufacturing shutdowns in 2020 explains the 2020 and 2021 numbers to a degree, but it is not clear why there would not be a rebound as auto rates increase. We would also expect to see a stronger rebound in polymer production in 2022, assuming weather events are less impactful than in 2021, given substantial new capacity for polyethylene from ExxonMobil/SABIC, BayStar, and Shell.

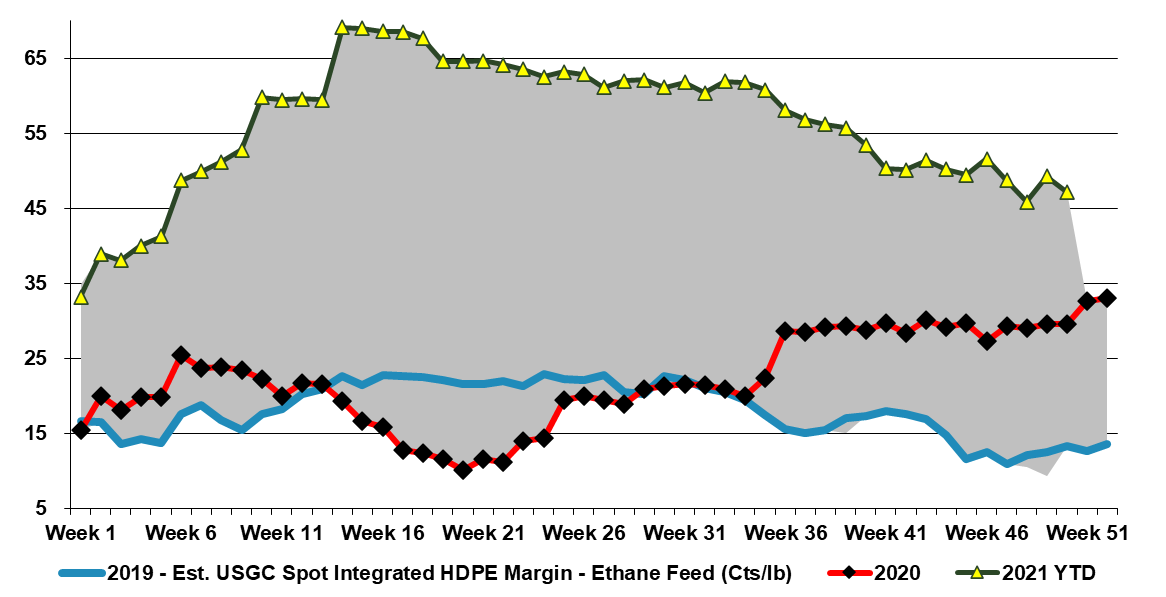

US Commodity Chemical Producers Face More Margin Pressure

Oct 6, 2021 2:32:43 PM / by Cooley May posted in Chemicals, Propylene, Ethylene, petrochemicals, feedstock, US Chemicals, specialty chemicals, commodity producers, downstream producers

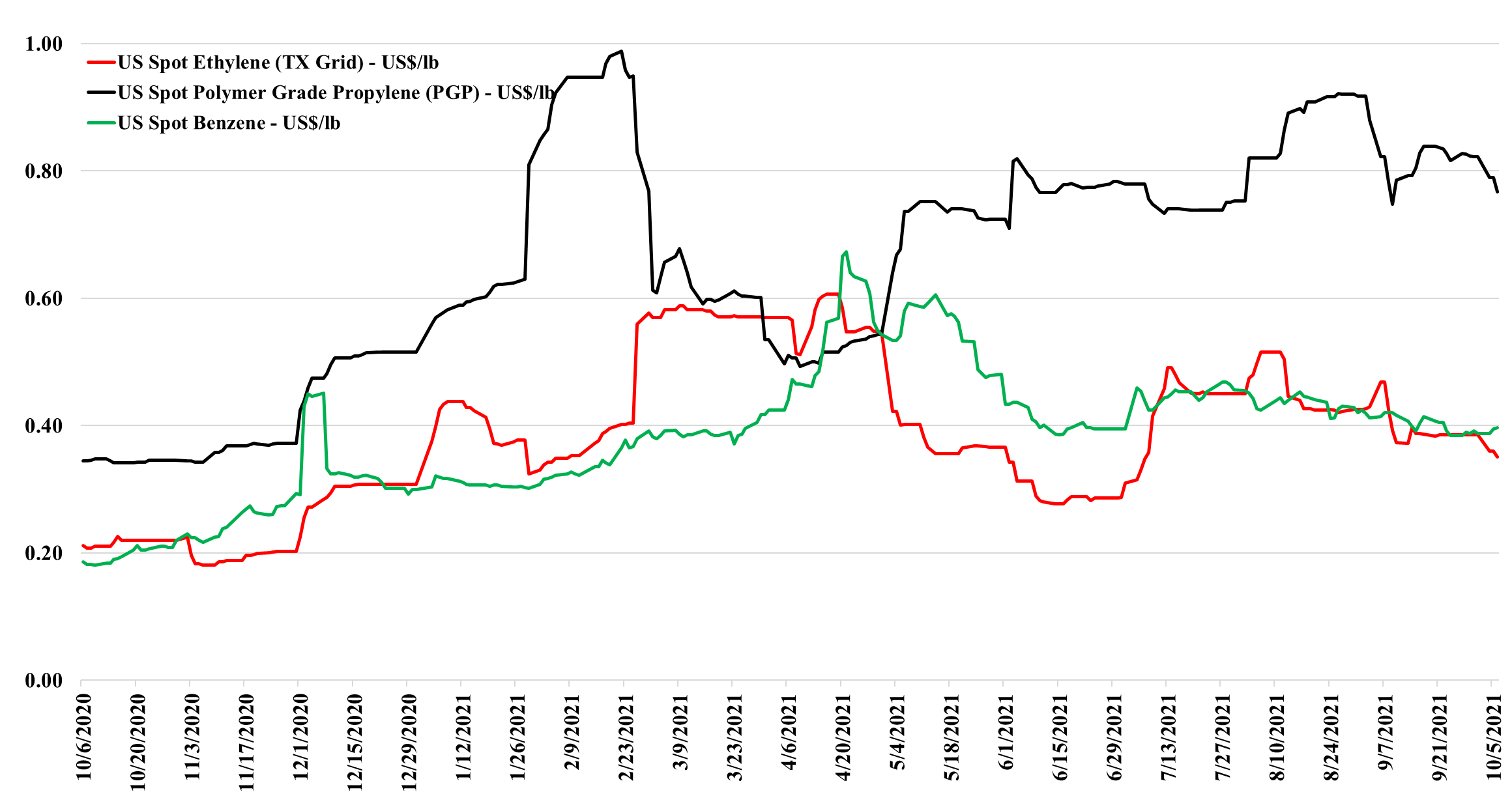

The decline in propylene and ethylene values is worth consideration today as it provides proof, along with the feedstock comments in today's daily report, that US commodity chemical producers are on average facing margin pressure WoW. We noted in yesterday's research that China prices were rising amid production cuts, but demand remains a notable concern. As production rises from current levels in 1H22, this will put downward pressure on Asia chemical prices and also translate into lower US export values.

Operating Leverage Spurs Downstream Profits, Combats Raw Material Cost Inflation

Aug 12, 2021 2:15:14 PM / by Cooley May posted in Chemicals, Propylene, Raw Materials, raw materials inflation, downstream, Basic Chemicals, Kuraray, specialty chemicals, commodity prices, basic chemical markets, commodity producers

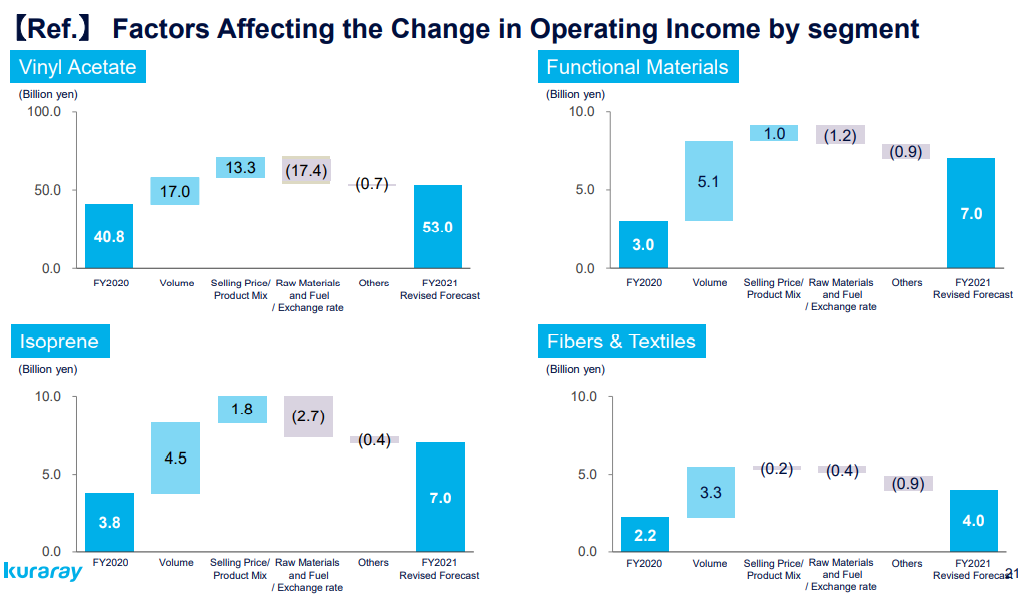

The 2Q volume driver of Kuraray’s earnings recovery was substantial, partly because end-market demand is strong and because this more mid-stream and specialty portfolio has significant operating leverage, much more than you would see from the commodity producers. We find this as a notable downstream sector trend to keep in mind. As seen below, increased selling prices are an important driver of Kuraray full-year profit growth expectations, but the volume piece is the most critical component, in our view. As discussed in our daily report today available in LINK, we continue to see volatile but elevated basic chemical prices.